-

Posts

4579 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

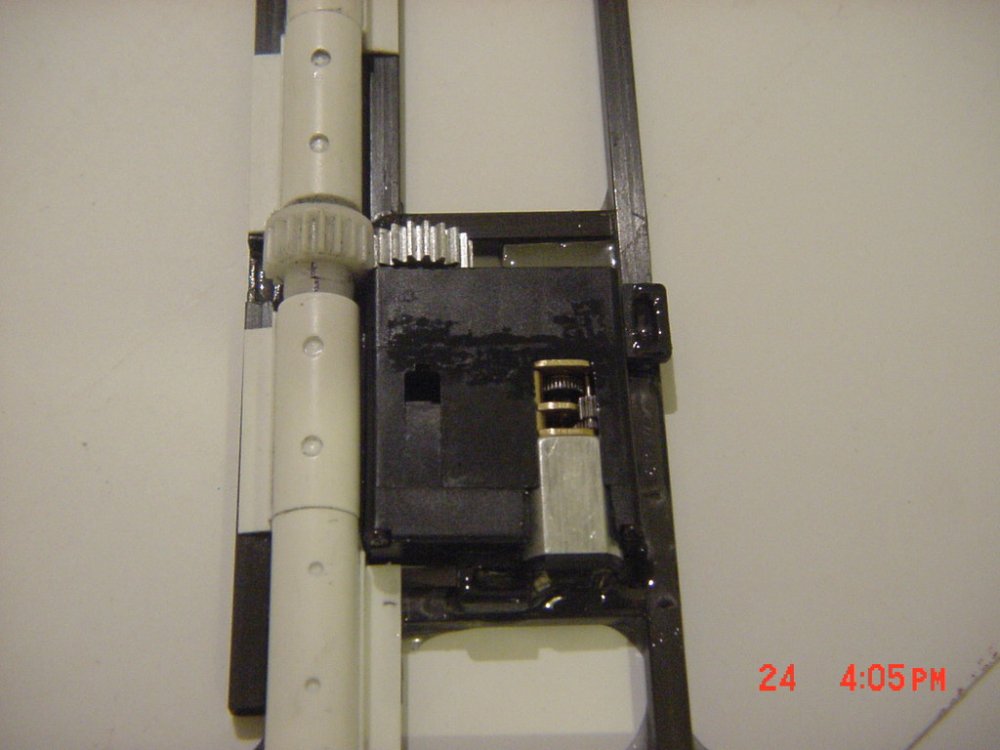

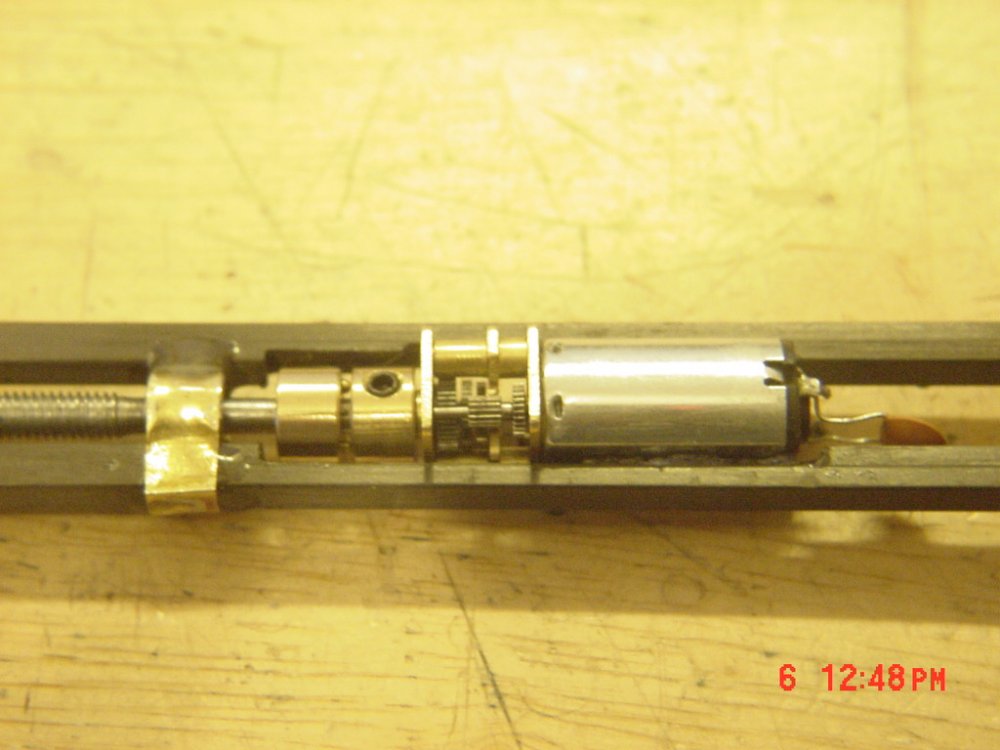

Thanks everyone for your support! IAD, sorry, I thought you meant the final drive gear chain. The final drive gear is a Hitech servo arm with the arm cut off and the core epoxied into an old Tamiya car gear. However, Servocity has these: http://www.servocity.com/html/servo_mount_gears.html. I made another one last year to rotate the drive motor pods on the lower hull. Rotorhead, thank you for the help. I posted this earlier: "Chrono, The top will open up with either a servo or another type of screw and lead mechanism. It's on the very top of the hanger so weight will be the biggest issue; especially with the door construction." You are right. The screw drive is the way to go. Helping someone fix a flat tire gave me inspiration after using a jack with a screw drive. Thanks Isamu for the offer! UPDATE 12 December 07 Well, at least a small one anyhow. Good news and bad news. The bad news is that when I put a rail on the other end to support the ramp, there was too much drag and the ramp kept going back at an angle causing the drive to drag badly. I thought from the start I'd put the drive down the center (one drive, one motor, less weight). I tried to put the drive on the side for better appearance and now another setback. The good news is that I am putting the drive in the center with two light weight rails on the ship sides as guides. With the drive in the middle, it will always pull/push from the center solving my problem and keeping the weight and complexity down. Where the drive will go (blank tube showing location). I cut off the angled supports and soldered two square tubes on either side. The tubes are almost flush with the edge, but not fully to allow the edge of the deck to rest on them. The drive will sit flush with the floor in the center of the hanger deck. I didn't want anything in the middle of the floor; but oh well! Note the modified gear case in the photo (flattened end). The motor is a rewound Mabuchi 280 with added ball bearings. I think I will go with a Mabuchi RS-555 (12v) motor instead. Lots of quiet torque and no gears at only 3v! It just weighs more! Now I gotta go make it fit in the deck nicely and cut carefully! - MT

-

VF-1S Strike Battroid Valkyrie step-by-step

MechTech replied to DrunkenMaster2's topic in The Workshop!

Looks great man! - MT -

ALL those kits look great! The variable kits have a special place with me since they were the first kits I ever built from Macross - before I saw the series! I just got tired of building 2-14's, 2 SR-71's, 3- A-10's etc etc. - MT

-

ce25254, I couldn't do a lot of my work without a pinvise! This place is the bomb: http://www.micromark.com/ They are in NY so shippping should be quick. Search "pin vise" and take your pick! 21105 is comfortable for first time use. Then you'll NEED a #60362 set or for the tiny (smaller than needles) stuff #82416. Search for "drill sets" and be amazed. Hope that helps! - MT

-

That looks awesome man! I wish I was that far along! As far as weathering goes, the only recommendation I have is to add some panels lines in a slightly darker red. The other question is how "new" is it. If it's been in the water for years and its in dry dock, add some rust and barnacles! If it's new, the panel lines still help give it depth. Experiment on on something disposable before touching your beautiful ship. Keep it up! - MT

-

YEAH; models are cool! I won't tick off the toy guys though . - MT

-

First off, thank you guys for ALL the compliments. My regular job has little to do with this stuff; so it's a lot of fun for me to figure stuff out like this and make it work. Even my wife got in on the project with interpreting the drawings. The good and the bad of Miyatake's Daedalus drawings are that the mechanical parts are vague in how they work. That lets me make stuff up to a degree. Isamu, if I get stuck, I'll PM you for help! LL Cool VF1J, I told my wife what you wrote. She and I busted up laughing! All I can say is take stuff apart when you're a kid to figure out how it works. When you grow up (and your parents stop yelling at you for breaking their toaster), then you begin to start making your own stuff. Of course you're probably already grown up (is that you're toaster squirming in the background?). I'm still always taking stuff apart (some of it you've seen pictures of ). Seriously, challenge yourself to build something new; you never know until you try! IAD, the servo is a Hightech HS-125MG. It's awesome. 3Kg of torque (4.8v), dual bearings on the spline gear. All that for 10mm thin (see calipers in photo)! You can buy them all over. Just Google it. I bought mine at the local hobby shop. The smaller gearcases (also 10mm thin were from Solarbotics.com (Canada). In the UK, Technobots.co.uk sells them. Servocity.com is also an excellent source for ALL KINDS of servos (U.S. I believe)! Chrono, The top will open up with either a servo or another type of screw and lead mechanism. It's on the very top of the hanger so weight will be the biggest issue; especially with the door construction. I'll update with photos Sunday hopefully. - MT

-

Thanks guys! So far so good with the other stuff. Posts later on in the week. - MT

-

No matter what you do, you're pilot will always be underaged . Looks great. - MT

-

Looks good so far! I'm glad someone else had a productive weekend. - MT

-

There really is no good match for train stuff with 1/100. HO Gauge is 1:87 and N gauge is 1:160. Building in 1:200 makes life rough for me sometimes trying to find stuff. Preiser's figures though are spot on. Get a dude sitting down and just make him holding a helmet . Other than that your back to busting open a kit or casting a copy. - MT

-

My head is usually burried in the models due to hobby and lack of time. But when I saw this topic pop up I had to chime in! NO WAY AM I TIRED OF THE VF-1! (In a very non confrontational voice ) Almost every company that makes cool Macross stuff started out with the VF-1. It's the best, the original, it's what made Macross what it is. In the 80's it looked really awesome too before stealth came on the scene for real. Henry Ford got started with the "Model-T," Macross's Crew got the VF-1. Both are classics! - In my VERY humble opinion... - MT

-

1988. Those were the good ole' days! You could find those things all over it seemed. I had the same Robotech kit, but it was the VF-1S. Mine has not faired nearly as well as your Bandai kit ce25254, but I still have the pieces. The scratched up decals will be nearly impossible to fix. You never forget your first and favorite Valk! At the very worst it will sit in an urn on my mantle someday ! Thanks for sharing. - MT

-

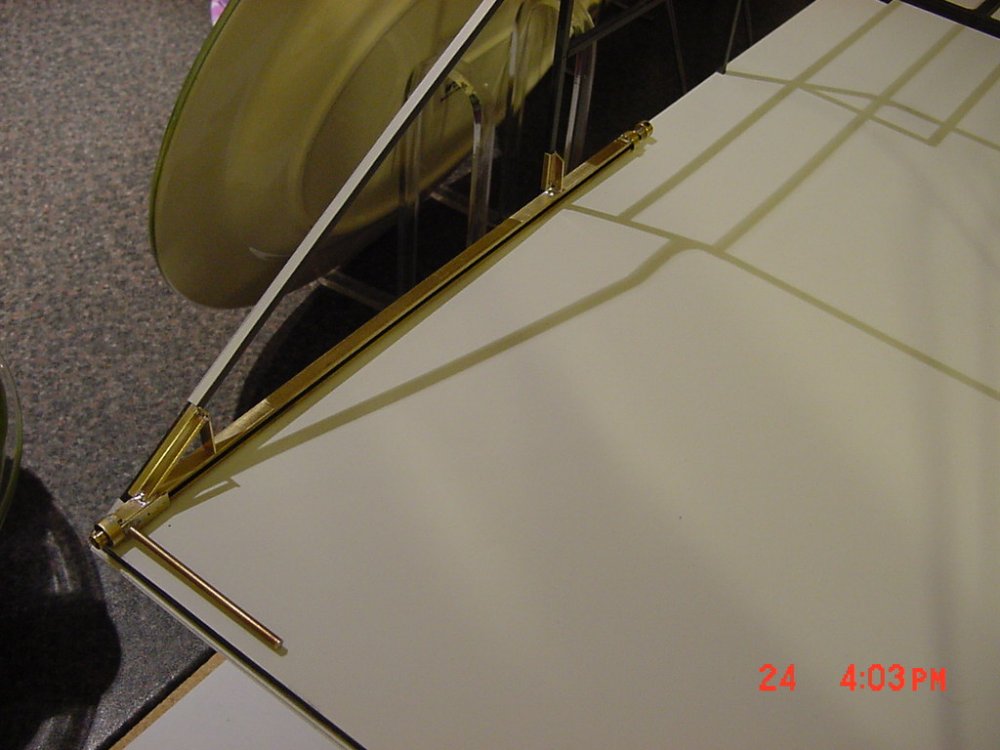

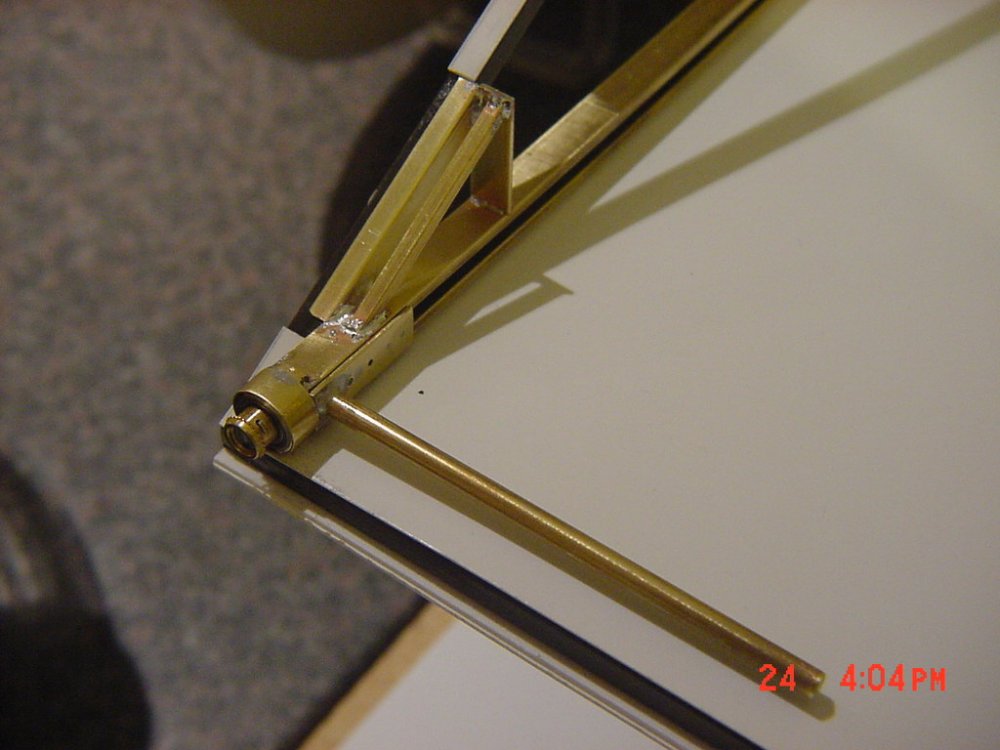

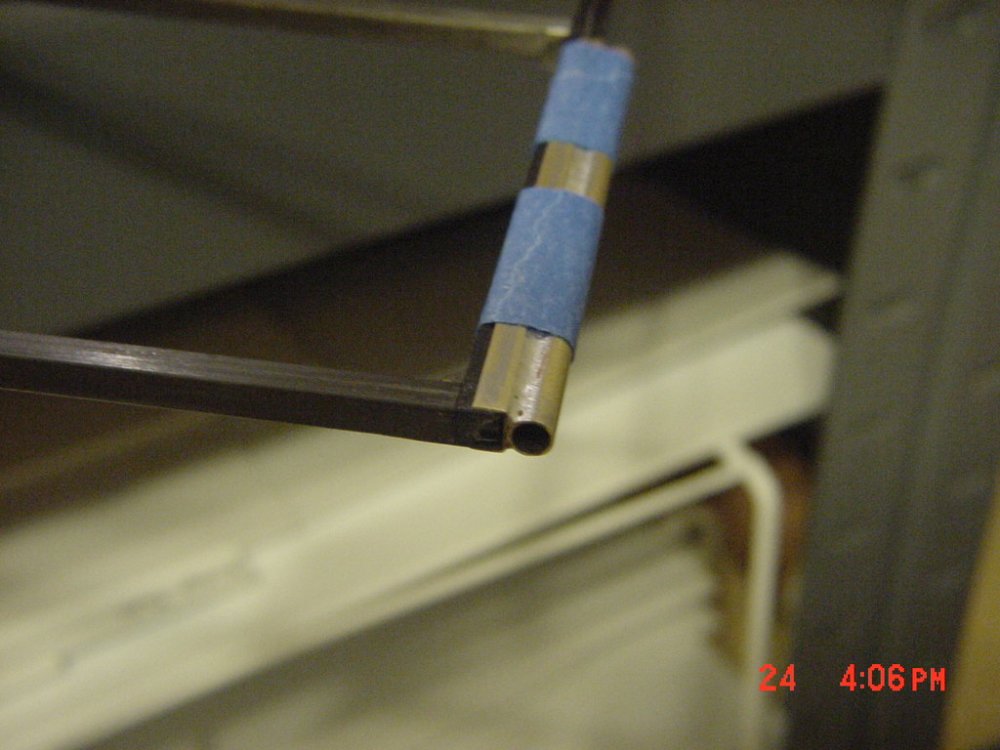

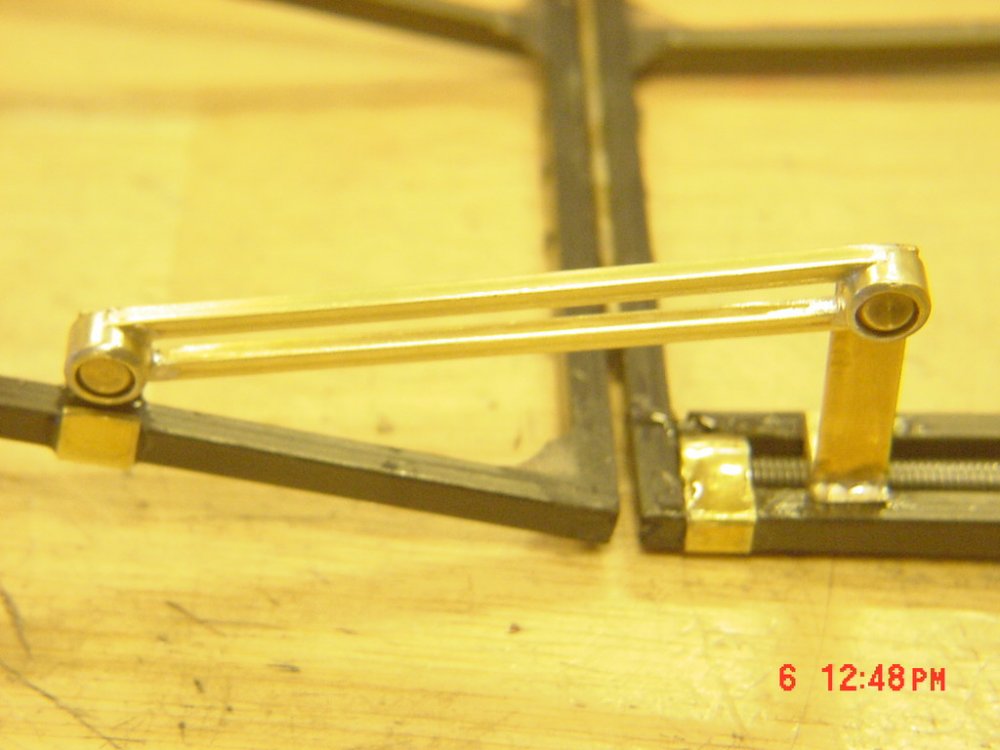

Thanks guys for the comments and a HUGE thanks Dave for sharing that link! I love both the IJN and Space Battleship Yamatos! Someday I'll build my 52" long Nichimo kit! UPDATE 24 November 07 I've finally got most of the problems worked out and I'm back on track (and short a little more money too ). The retract and fold mechanisms work great. I've made everything kinda on the slow side for dramatic effect and realism. A giant ramp that size would not just flop down and quickly fold shut with any technology so that's what I'm shooting for. No video yet, but the whole sequence would take longer than what we can upload here so I'm trying to figure out what would be the best solution. First the biggest problem; getting the ramp to fold over 180 degrees on itself (with a small / thin gear case and motor). First I took an awesome ultra thin servo (dual ball bearings-metal gears: see the box) and took one of those awesome tiny geared motors, a lot of machining and stuck them together! I got a smooth, slow and POWERFUL drive to fold the ramp. Don't ask how much it cost - I stopped counting . Next is the linear drive for the ramp. It's that "C" section of tube from my last post with ball bearings at either end. The recycled clutch from my previously made fold mechanism was reused. An overall view of the whole drive minus the gear case, motor and ramp. The reinforced front end and mounting bracket (grips CF framework). And the gearcase "interface." Everything works great and a little 30:1 ratio gear drive with only a RE-280 motor on it works great! That pole sticking out of the drive slips into the ramp hinge point. I just have to make the rail for the other side. It will move only to support the ramp and hinges, it will not be powered; only the side you see. The trick was making this all work and still look like it belonged on the model; not a toy. Everything works together, I just have to put it together permanently and record it on tape. Some ball bearings will probably be put under the ramp to help it glide over the edge of the hull better. An arm on the ramp will catch as it goes back and make the middle part fold upward. That is the next engineering step before it all works like it should. Talk to you all later. - MT

-

Nice job on the decal graphics! - MT

-

You know, I'd sell the cockpit seperately as an option, just an opinion. I would seriously consider buying one. - MT

-

Has anyone actually ever completed a Nichimo 1/200 scale model kit?

MechTech replied to drkstar00's topic in Model kits

I'm glad to see this thread is still alive! Nice works guys! Especially the scout mod. - MT -

If you get desperate, check out Preiser's line of figures - here's a sample http://www.ontracks.co.uk/index.php?page=c...&toplevel=1 Scroll down and note the the guys in orange jumpsuits. They are perfect maintenance crews for the Valks. Get them in orange if possible (see my avatar). There has to be a Preiser dealer in your area. - MT

-

Looks great! I always did like that design. - MT

-

Has anyone actually ever completed a Nichimo 1/200 scale model kit?

MechTech replied to drkstar00's topic in Model kits

That looks great man! Especially for the scale. If you haven't seen this yet (in another older post), check this guys stuff out: http://www.geocities.jp/sidenet_note/sidem...dematerial.html . Awesome Macross models in there (serious 1/200 mods). - MT -

1/60 YF-19 Gerwalk Locking Chest Mod

MechTech replied to Lonely Soldier Boy's topic in The Workshop!

I don't have one; but great idea! - MT -

1/4", yeah, I think you're safe! You could hang your grocery shopping bags off that too ! So far so good. - MT

-

Ions ago I had the vinyl kit and loved it. A dream trip to Japan, I'd love that too! Keep up the great work. - MT

-

Update 11 November 07 Hey everyone, those stupid laws of physics have been getting in the way again! Long story short, there is not a powerful enough and small enough gear motor that I could find on the market to drive the folding mechanism and still keep a realistically low profile (and do it fast enough). Here's what I built and am not using (...again) and the updated version. Here's that beautiful gear motor (these little things rock!) and the clutched linkage I made for it. It's just not strong enough (with the voltage doubled and a bigger motor put on it too!). Here's the folding linkage with custom crafted ball joints. They worked great at least! Here's the whole assembly. A length of threaded (and machined) rod drives the arm to retract the joint. There's a problem with the fulcrum and power of a small profile motor. It works great at any angle OTHER than at 90 degrees when the ramp is fully open. Other than that, it works great! Another shot overhead. The fix... I took a 1/4" square brass tube and machined a slot all the way down it. The threaded rod will be inside and the nut will ride inside that too. Then a regular sized gear motor (hidden in the side of the ship) will drive the whole thing. The back segment of the ramp will ride that whole thing forward and backward with standard tracks on the other side for support. A lever will then catch and fold the middle segment within the same movement. The final segment will fold on it's own with a modified servo. Hitech recently came out with a metal geared low profile servo that should work (HS-82MG). It's tiny with the same torque as a standard servo. That's it for now. - MT

-

That's the most realistic box of Whoppers I've ever seen! And the dropship looks great too ! - MT