-

Posts

4701 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

The finished background looks awesome! Definitely 1/72nd scale accurate. I'm just waiting for battle stations alarm to sound looking at the picture . - MT

-

How small are those parts? If they are as small as I think, you can heat some plastic sprues and stretch them out. The long strands can be cut and you get easy antennae. They also taper out naturally so they look like antennae. Real easy to do. Great work overall! - MT

-

I thought I would check in after a while to see how this thing turned out. I'm disappointed with the rounded chest pieces and the really long shnoz on that thing. The opening missile bays are a really sweet touch though! - MT

-

It looks great all the same! That kit takes a little work to make it look cleaned up anyhow; it's got some bad seem areas to work on. - MT

-

Looks great and on the realistic side! - MT

-

Bandai 1/72 Scale Macross Frontier Plastic Models

MechTech replied to Graham's topic in Hall Of The Super Topics

I wouldn't rule out a quality sculpt for Bandai. A lot of their kits have awesome detail in them (most anime stuff doesn't have a lot of panel lines or details to start with). They've also got some heavy guns to bear in the molding department. The 1/20 Votoms kit I purchased has awesome detail and a few multi - slide molded sprues. Painting will be a piece of cake with the way the parts are made. They make it easier on the modeler instead of putting seems in the middle of everything. I also haven't had a styrene quality issues with them before. Other well known brands I have (not Hase). - MT -

Ditto... - MT

-

I bought the Robotech packaged kit about 20 years ago. I walked into a unique collectors store and it was sitting up on a shelf right above the doorway with tons of dust on it, unopened. This was a couple years after all the kits were sold off the shelves. I got it home and thought, "Thank God, this is like the holy grail of Macross stuff - awesome!." Even when I saw it in the store I played it down. It was an "expensive" $38.00 . - MT

-

Try looking up the top of the main for customs under the "robographics" thread (pinned area) - or- http://macrossworld.com/mwf/index.php?showtopic=21527. He might be able to hook you up with a set. - MT

-

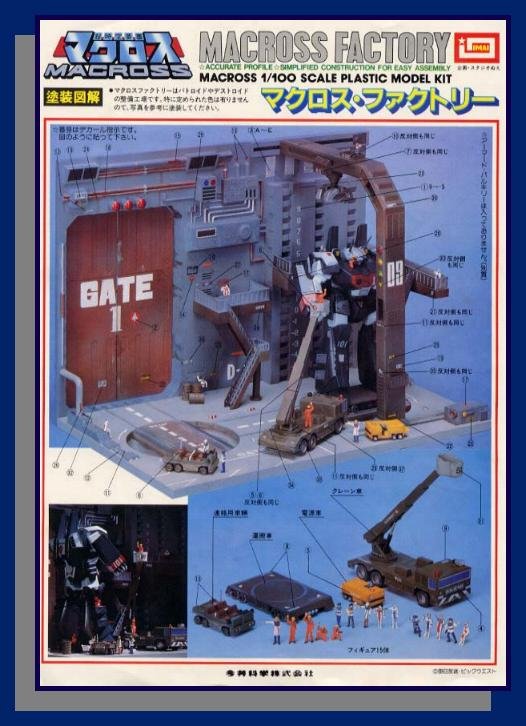

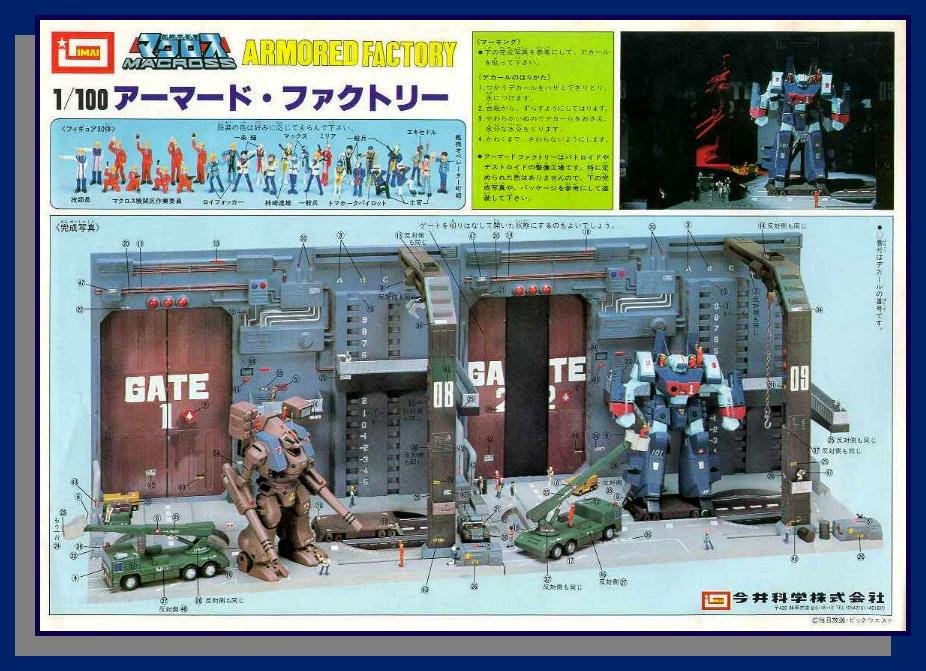

You mean these? If that's the case, yes, 1/100. All accessories (unlike other kits like this) are 1/100. - MT

-

I haven't seen carrier stuff (please share if you have) but... http://store.houseofhobbies.com/he1acgrsueq.html and http://store.houseofhobbies.com/he1acairfope.html click on the photos to enlarge them. I've got them and they're great! Add some orange paint to the figures and voilla! - MT

-

Yeah, I've got some; just nothing in 1/20th scale yet . - MT

-

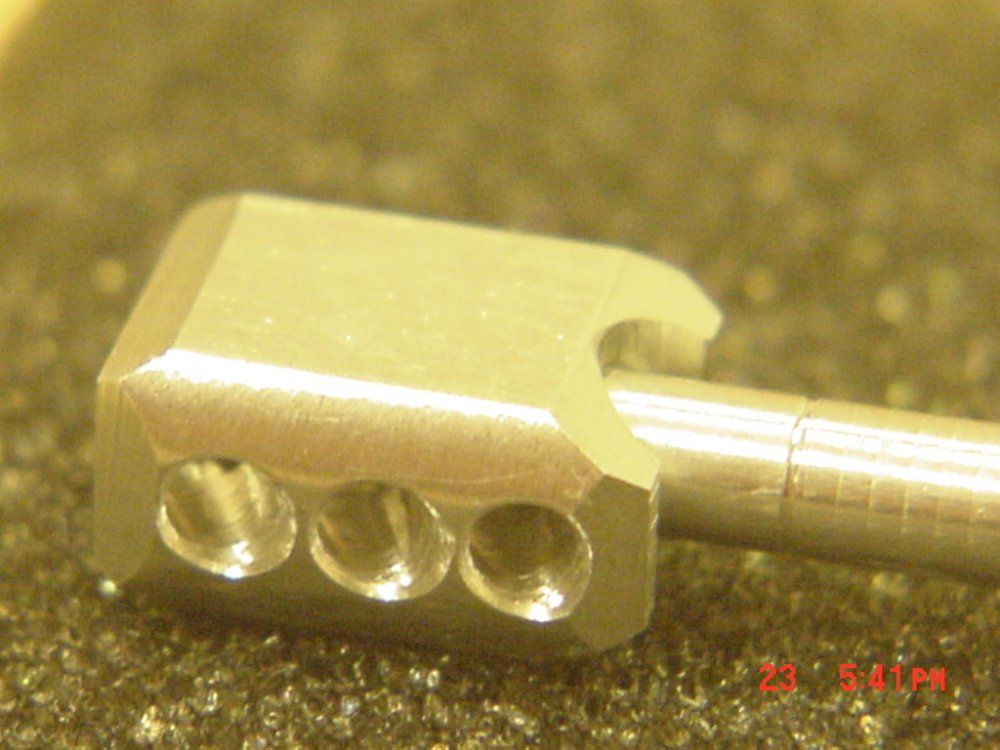

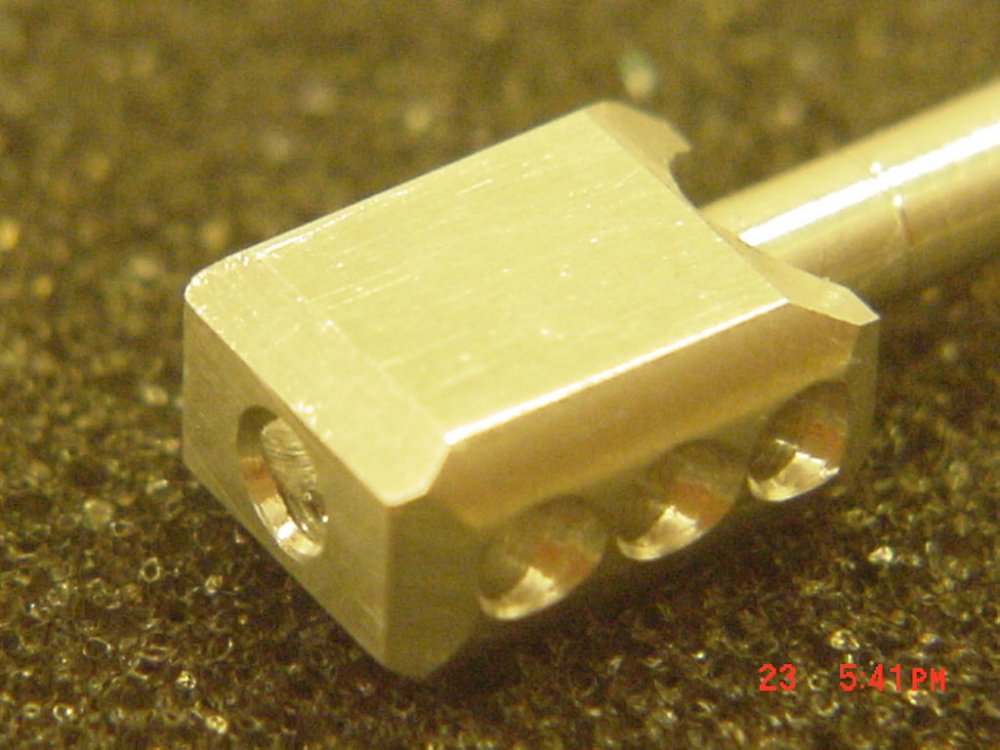

Well, I finally did some modeling/machining today. When I get the time (and my Votoms books) from HLJ, BeNippon, I'm getting to work on my Bandai 1/20 Scope Dog RSC. It is an awesome kit and hyper articulated. I thought I'd upgrade it with better armament and details like photo etch and spring hoses. I remade the main camera "eye" from an old aluminum Tamiya gear. The machine gun will have an upgraded longer barreled cannon, with a fancy muzzle brake I made up from an old piece of R/C car shock absorber. (note the 45 degree angled exhaust) The barrel is a Lion Roar Pak42 L/70 barrel (for a Jagdpanther funny enough HWR). For years I've had the Tamiya 1/35th scale 75mm brass ammo just waiting to be used. In 1/20th scale it looks like it's 35/40mm ammo so it's perfect. A few spent "rounds" on the model base will look more convincing. A couple on top of some magazine would be cool too.

-

Graham, thanks for keeping us clued in and not in suspense! Many thanks!!! LeDudeModele, you heard me yelling all the way to Canada, I better chill out . I think the reason the other toys are 1/60 is that it seems to be a popular scale in Asia. Even Votoms stuff was available in 1/60. We're not the only fanatics. A little background on why 1/200. In Europe during WWII and afterwards, a 1/200 scale model is the size a fighter would be at arms length (simulated) if you engaged him in combat. There were many kits in that scale from then on afterward. 1/200 is now very popular for conventional aircraft; military and civilian. Plus it is small and takes up very little room. Less plastic, more profit. Less space on the shelf too (Japan isn't known for having giant living spaces). Plus they're really cool looking that small - IMHO .

-

You guys have been busy. A chick with an M-60, Custom armor, and one of the newer Tamiya R/C Tanks? I finished the A5 to A6 upgrade on my Leopard. The thermal sleeve connector towards the front of the barrel is a little thick, but I took a shortcut and used a segment of PS tubing that fit snug after some work. The paint is a little darker towards the front, but oh well. It's just for driving around the house and fighting with my children's tanks! - MT

-

Thanks!. The Daedalus project is over two years old now. I finished the Leopard conversion (short-easy job). I haven't been really building anything and it's driving me nuts! I'm just too busy studying for some job related tests. I've even got the awesome 1/20 Bandai Votoms Red Shoulder Custom sitting in my closet and it's driving me nuts! Every time I go in to get my clothes, it just sits there staring at me . - MT

-

OK, I'm a model guy and I know that's a messed up price! Throw your money into the fireplace, it'll keep you warmer . - MT

-

Somebody heard me crying out 1/200 FINALLY!!! Time to start saving! - MT

-

Those look awesome cool8or! Don't overdo the weathering like others said. They look great already! I don't know about the "Public Enemy" Poster though . - MT

-

Great idea! See, there's always something new to put Macross on. When they make toasters and hot pots like they do for "Hello Kitty," my wife is getting them for Christmas ! - MT

-

Looks great! - MT

-

That paint scheme is really snazzy! It's tough getting clean lines like that. Congrats! - MT

-

Thanks for the update! - MT

-

Sorry jipe, that's all I have left . You REALLY want the Macross Perfect Memory book. I didn't have it and made a few mistakes using limited resources with what I built. The book is still around for retail if you Google it. LOTS O' SKETCHES! It's the greatest resource book next to the big expensive gold one! - MT

-

BUILD IT! Build it! You know you want to ! I think you should give it a shot. Some of these guys are talking about filling seems and stuff. Toys have seems and you're cool with that. Every skill is on a learning curve anyhow. build it...build it...build it... - MT