-

Posts

4305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by wm cheng

-

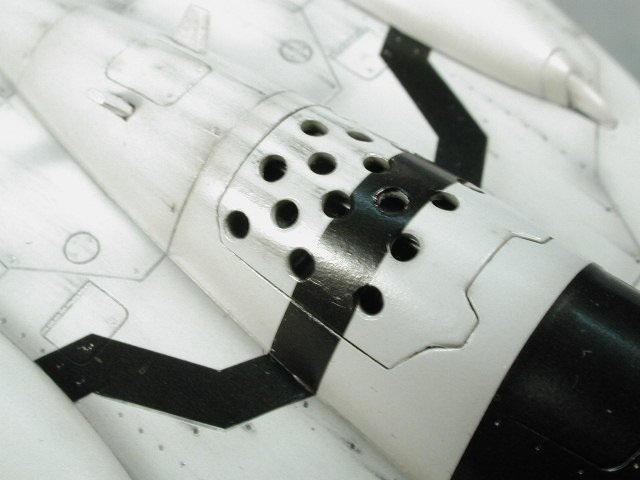

Here's a close up of the airbrake, its easier to weather with it in place and decal it so that they all recieve the proper placement. I just decalled right over the holes - then when its semi-dry, I dabbed some MicroSOL right over the holes, and the perimeter decal just kind of "melted" right into the holes. Just the center hold remained, but a few more drops of MicroSOL, and a little encouragment from a small brush and the center hole gave way.

-

-

-

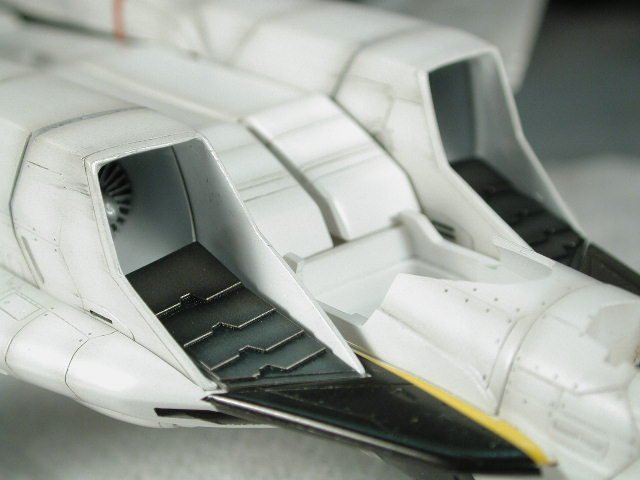

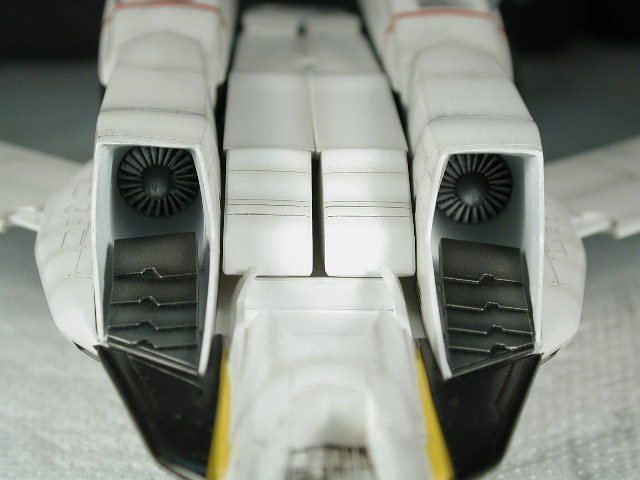

So now they look like a moveable piece. I wasn't anal enough to extend the width of the intake covers to both ends to meet the walls of the intake - but it just looks like something that moves in the intakes (artistic licence )

-

I wanted to glue all those loose parts lying around on to the bird as soon as possible - I just know they'd be lost soon - plus I'm impatient I thought it might be cool to angle the intakes like the F-14 intake ramps a bit and partially obscure the intake spinners. What I didn't really like on the YF-19 was how flat these intake covers look when glued right up against the top of the intakes. So I bent the last segment of the cover up a bit (careful, you don't want to snap it off, just a bit) and I glued a cut-off piece of sprue underneath it to wedge it up a bit.

-

So did you guys hear my screams through cyberspace! Well, it didn't work out very well at first, man that SET and SOL combination really "fused" the decal like "paint" - no amount of tape was pulling it off - just little bits and chunks, really made a mess of the whole situation. To pour salt onto wounds, I was pressing down with the tape to lift some more of the decals up, and SNAP! one of the lower ventral fins (black & grey) snapped off - DAMN! I knew it was a weak joint, so little surface area to connect the fins to the legs - I thought of re-inforcing this area with pins like with a resin kit, but I was anxious and wanted to get on to the next stages, so I coped out and used liquid cement thinking it would be less sanding later on. Well... now I know, I would suggest re-inforcing this joint next time - or at least use tube solvent glue liberally, and then sanding the seam down before painting. I hate these repairs. Well, a few hours later, the fin is back in place, the joint is not ideal, but less noticable than I thought it was going to be, the black decal hides a host of sins And as with all repairs, it will be weak, so I have to watch out for it. The decal mess being too long was then solved by soaking a bit of MicroSOL on it for a bit and using a stiff bristle brush, carefully scrubbing the extended portion of the decal away without going too far into the paint finish. Thank God for the clear-coat underneath. Anyways as you can see, it looks okay - I didn't bother with the one on the inside of the legs, you can hardly see it anyways.

-

Thanks Jesse, What do you mean by cutting down not slicing - won't that tend to rip the decal? And what do you mean by "tacky" - do you mean before its dried? Unfortunately mine is very dried, and "fused" in there with lots of SET and SOL to get it to conform to the crevice. So any help would be good. Maybe I can try to very cleanly slice it, and use tape to lift it up off the plastic - without scraping it with a knife (learnt from that old radome mistake on the VE-1 - maybe it will be good for something afterall ) I'll let you know - otherwise you may hear me swear all the way through the internet

-

Hmm, trimming them after a clear-coat eh, what does the clear-coat do? I am tempted to try, but I'd hate to make a mess of it. I am afraid the combination of the SET and SOL has "fused" the decal to the paint. It would be fantastic if it just came off - flaked off - but I'm afraid I might need to scrape it, and I might damage the paint underneath. I'm not sure about the home-made stuff, it kind of depends on the brand and how many coats of decal film was applied to it afterwards. It certainly is not as thick as Anasazi's decals for the Yamato 1/48. It is thicker than Microscale, that's the thinnest stuff I've ever used. In fact some of it has desintergrated right in my decal box over time. I'd say its like Cartograph (from a few years ago - the last time I have had the pleasure). I'd say its great thickness, not too thin, not too thick - its just that I wasn't used to it, I was expecting the practically indestructable VF-1 type decals. Yes, those sweep areas behind the wings are decals.

-

-

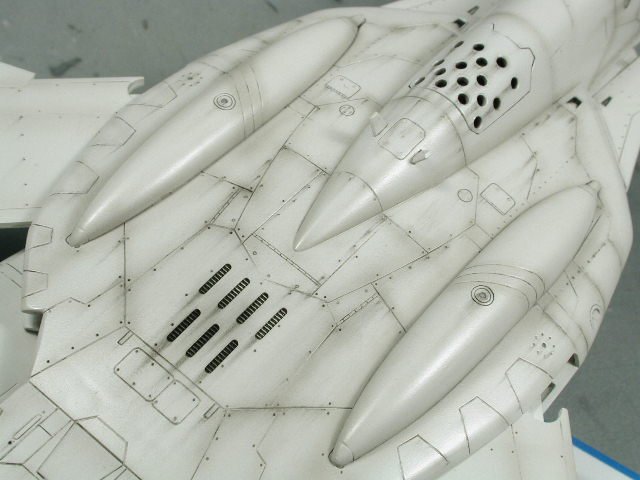

I love the fact that Hasegawa has thoughtfully provided so much of the black markings that otherwise would be another few days of masking. I finally glued the legs in!! I love how this plane looks! Its a shame I have to put landing gears on it and ruin the sleekness - oh well, I just might have to build another one with the gears up.

-

-

Wooohoo! decalling stage - my next favourite step These decals are quite thin, compared to the other Hasegawa stuff. They are very good, but I was kind of used to the other stuff and lathered on the MicroSET liberally and was a bit rough with them, as a result, I ripped a few here and there before I got the hang of the new thinness of these decals. They are great, don't get me wrong, just a little thinner than I was used to from Hasegawa. They are also a bit over sized - I'm not sure whether they are actually oversized or that in combination with the MicroSET softening them and being thinner, that they stretched a little bit. As you can see here at the legs, the black stripe is supposed to end at the knees but there should be some white showing on the lower bulkhead - the black is only supposed to be on the part that bulges out. I already had too much MicroSET on them to neatly trim off the excess length, so I just kept them as clean as I could, luckily the profile of the black stripe matches the knee portion perfectly so to the "undecerning" eye it looks intentional. Unfortunately the photo doesn't show all the little details that must telegraph through these black stripes. I used a bit of MicroSOL on the panel lines and those triangular recesses near the knees to get them to show through the decals properly. I think the next time I do this, I might just mask and paint the black stripes on the legs - its a pretty easy shape and all the details will show through. I chose to decal this first since I want to glue the legs onto the fuselage as soon as possible (just anxious). I will probably omit the numerious warning stencils on the inside of these legs (keep them as spares for my decal box) since they are totally obscured when the legs are attached. The ones that do show are still accessible after the legs are glued in.

-

Hey David, looking forward to your new F-14 analysis. Does the Fujimi kit's wings swing - that's the bugger for me on my Hasegawa kit, you have to choose which position to place them in. Can you include a photo of the Fujimi box (I am interested in the re-issue with the Jolly Rogers decals) do you have a part number for it? Secondly, can you also include the box of the newer Hase F-14D? I might just switch over to Fujimi - never built one before... but you're convincing.

-

Club M - Nearly Done! (okay..still a while away)

wm cheng replied to Myersjessee's topic in Model kits

Congrats on the coup! What a great feeling to have your collection completed. Now I want to see step-by-step theads from you very soon!! Forever long live 1/72!! -

Hey anyone with a subbed version of Operation 4?

- 1076 replies

-

- yukikaze

- sento yousei yukikaze

-

(and 6 more)

Tagged with:

-

I just remembered that excellent article that David pointed us to about Naval weathering, it suggested another coat of the base colour to tie everything together. I thought this might be my chance ot lighten the whole bird up again. So I mixed a very vicous (lots of thinner 60:40) gloss white and lightly dusted the entire model with it, concentrating to hit the highpoints and areas where I wanted to tone down the post-shading and weathering. I like it a lot more now - everything ties together much more nicely. Although its still really dirty (a little too weathered for my taste) - but I think its pretty close to the animation now. I think I'm ready for decalling soon - woohoo! There will be another dusting to tie the decals in as well as weathering on top of them - but thats another story for later. I just want to glue those damn legs onto the fuselage - I guess I've got to decal the inner calf black stripes and the grey portion on top of the legs before I can make this bird whole again. Must take a break, goint to see "13 going on 30" with the wife tonight (Jennifer Garner)

-

The whole plane looks a little grey now - its not what I really wanted. I wanted a weathered white plane (well slightly off-white, very light grey) Its gotta eventually go next to my VF-1 on the flightline.

-

-

Here's my reference. I know David, its too heavily weathered - but hey not all aircraft have to survive an avalanche of rocks and debris

-

Well there it is - I just repeated the above process all over the aircraft, trying to duplicate the CGI reference where I could. Actually, the photos looks light, its actually more heavily weathered than this. I post the reference I used below this image.

-

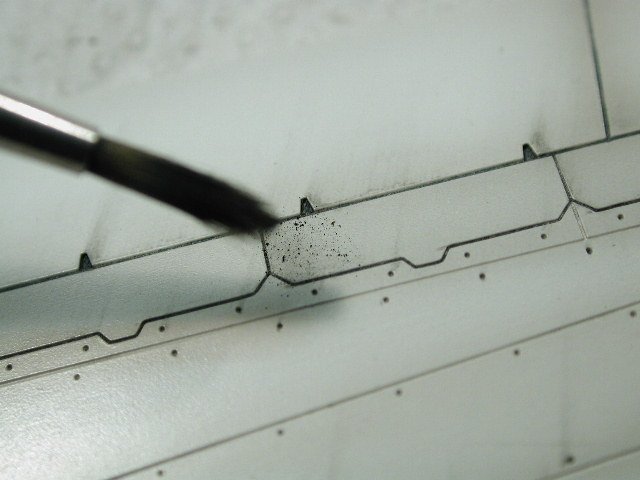

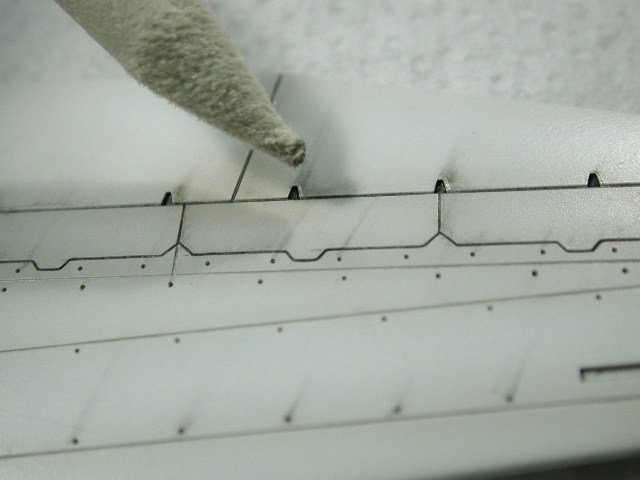

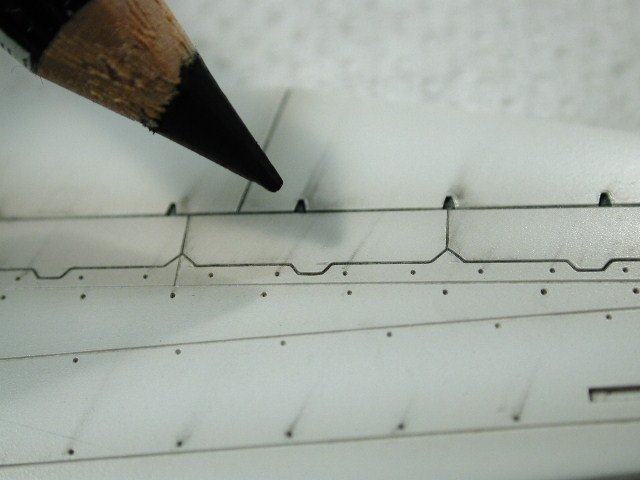

I noticed that on the CGI model, there are darker spots in the panelling especially around certain junctions where a few panel lines meet. I use the shavings and dab a dry brush into it and work the dust into the areas lightly where I want it to be darker.

-

I then used the smudge stick / shader to smudge the drawn oil streaks in the desired direction - then I use a paper towel to also wipe in the same direction. If I had to much, I would rub it with a damp paper towel or use the kneadable eraser.

-

Specific leaks I drew on lightly - I took David's suggestion and made the leaks in the direction of airflow when the wings are fully extended. This is a comprimise, since the CGI model (believe me I've looked carefully) wings streak at a nearly perpenticular angle to the trailing edge of the wings (not even fully extended would the airflow be in this direction!)

-

I use an xacto knife to scrape away at the pencil to create shavings/dust in a plastic container (battery packaging bubble) that I can brush on for general darkening not specific leaks.