-

Posts

4305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by wm cheng

-

I hand painted the rear interior of the legs black. Then I applied a wash of pure black to the metallic objects. I love the head sculpt - its too bad that you will see almost nothing of it when its buried into the fuselage. Its too bad that there was no clear piece for the top of the head which is supposed to have a red light at the front.

-

Here's a overall shot - kind of looks a bit retro eh? or cannon fodderish Once the panels are lined and the post-shading applied, the contrast will be less noticeable.

-

You can see the gloss white landing gear bay behind. Quite a bit easier than painting the white onto the dark blue YF-21 body!

-

-

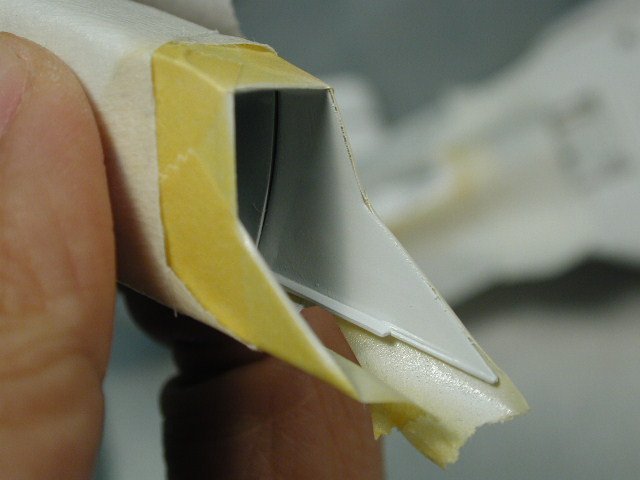

Here's a shot of the masking I did around the edges to separate the gloss white interior from the light grey exterior.

-

Here's a shot of the white interior which looks good against the light grey exterior of the intakes. You can see the original coat of sky grey inside feathered out to the gloss white - this exaggerates the apparent depth of the intake - kind of like painting a shadow. When the top is glued on, and the actual intake falls into shadow - the effect looks better.

-

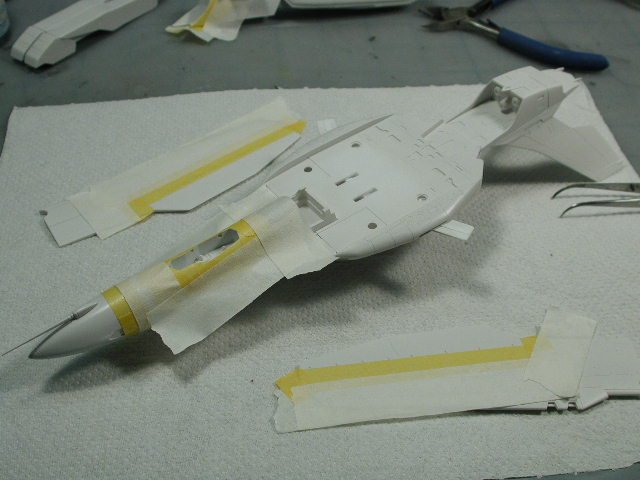

Here's a shot after the white spray on all the parts. Must leave to dry - DO NOT FIDDLE WITH IT! This is my most vunerable time - when I start to paint the different colours, and I loose patience and start to mask and handle the plane before the last coat is completely dry. I can't count how many scratches or finger prints I've had to sand off and re-paint over the years! I always try to do this late at night, so I have to go to sleep to let the paint cure. Or find something to do on another part of the model while the paint cures.

-

I'd decided it might be nice to spray the radome and flaps in gloss white too like the old Tomcats, plus it will differentiates the greys on the aircraft. Anywhere where I can liven up the straight white/grey paint scheme would be nice without going against canon art.

-

-

-

-

-

Hmm, I'm not to sure of the spray can - I have used the Tamiya white primer spray, and it goes on great for large areas, but I find the spray cans lay on too much paint and its too hard to control for fine details and small parts. Good to know though. I've been itching to try some of the different glues out there. I've just stuck to my old favourites over the years - for anything that requires strength, I use the Testors regular orange tube stuff. Smaller stuff I use the liquid cement - I've used the same bottle of testors for 6 years now, and finally I had to go out to get a new one - they had a sale on Tamiya (which puts in the same price as the testors) and I got that, don't notice a real difference though. Saw a neat glass tube for precise liquid cement placement, but it was too expensive ($25-30cdn) for now. I'd love to try that MicroWeld or MEK stuff - man, I didn't have so many choices in glues in my day - its really weird to be using the same stuff all the time and then suddenly look up and see all this stuff around you - it makes me feel old Can anyone let me know what their experiences are with these other glues - I'd like to know what to try. Like David, I'd like a little bit of time to precisely place a part (5sec) then have it hold the part or set soon (10sec) - prefereably something that doesn't ooze out the sides and can be very thin/vicous that can be precisely placed. Do they "melt" the plastic, or is it a chemical bond? Hey I'll start a chart with what I use: Name: Type: Play Time: Set Time: Cure Time: Testors Orange Tube Solvent (Thick) 15-20sec 30-60sec 4-8hrs Testors Liquid Cemet Solvent (Thin) 5-10sec 20-40sec 2-6hrs Crazy Glue (regular) CyanoAcrylate 0-5sec 5-10sec 30mins (-this stuff comes in all flavours, thin to thick, fast and slow, with accelerators) 5min Epoxy Epoxy resin 2mins 5mins 6hrs Hey can anyone fill in the rest - participation encouraged Good questions, I'd like to try some new glues next time around. Sorry, noticed that all my careful spacing to make the chart readable is ignored when I post - oh well - I hope you can make heads or tails out of it

-

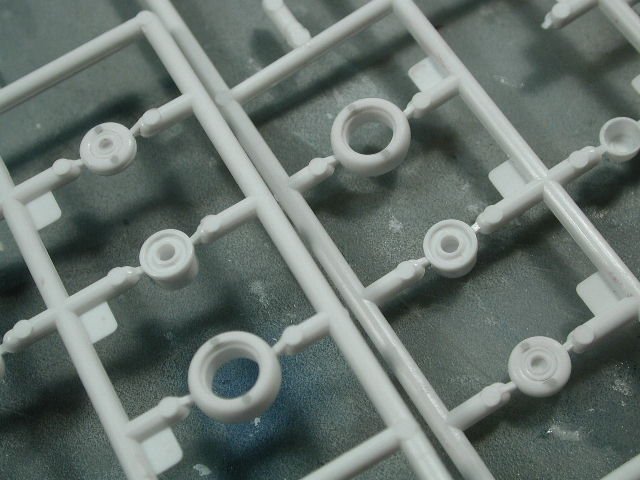

Again, there are injector pin holes/depressions on the wheels which needs to be filled in with a few coats of Mr. Surfacer (they were deep) and sanded down. Its wierd that there are so many pin depressions in this kit. I am going to give the bird its first coat of light grey paint today. Its a mix of 50:50 flat white with gloss white with 2-3 drops of sky grey. I'll let you know how it goes.

-

The two dorsal antennas had their leading edges sanded down at 45 degree angles to reduce their apparent thickness. The square edges just didn't contribute to the aerodynamic look of the aircraft.

-

Here's what they look like when they are done. I didn't do it to the nose pilots tube, it was just a bit too small - maybe someone would try it out and let me know, I'm just not that anal yet

-

I thought its about time to drill out the head laser tips, it will add a lot more realism to have the lasers hollowed out.

-

A shot of a dry fit assembly - I like the airbrake a lot with the hole drilled out, I think its worth doing even if you are gluing it down fold back. It lets you see into the brake well with some details inside.

-

Here they are after they have been sanded - it will probably take a few coats of white to truely get the grey spots to be white - why don't they make white Mr. Surfacer?

-

This makes it easier to sand away the holes that were filled in earlier with Mr. Surfacer while still keeping the surrounding details.

-

Here's a shot of those sanding sticks. They came in real handy when trying to sand the filled in injector pin depressions inside the landing gear doors. I'm lazy so I just bought a pack of these - but I suppose anyone can make them, just glue your favourite grade of sandpaper to little wooden sticks.

-

Hey Everybody. The metalizers I use are Alclad - you can get them at most hobby stores, they are laquer based so Mr. Colour thinner or ModelMaster Acryl thinners and solvents work on them. They are great, found them on the Yukikaze model thread, and I will never look back. The great thing is that they do not need a sealer nor buffing - although it does say that buffing will improve the look - I haven't had the need yet. Most metalizers require a sealer, and the sealer often dulls the shine down - which in my opinion kind of goes against the effect you want to achieve with a metalizer. They are pre-thinned to be airbrushed (so its a bit expensive for what you get, those little bottles are around $12cdn - maybe $6-8usd) and must be airbrushed. The gray primer is also pre-thinned and is excellent - they are sprayed at a lower pressure around 12-15psi is recommended on the bottle. With these and all metalizers, the surface preparation is essential. The smoother the underlying surface it is, the more mirror/glass like you finish will be. I would spend extra care in filling or sanding any pieces that are to be metalic, since the sheen will often catch the light at odd angles and exaggerate any flaws in the model. I do prime the parts first with the primer before using the metalizer - te primer tends to to smooth things out a bit. With the polished aluminum or chrome, they even suggest a coat of gloss black after the primer before the metalizer. I've tried it both ways, and you really need the gloss black underneath, I think it acts as a mirror with a backing - the shine achieved is well worth the extra step. I'm ready to give it the first coat of light white/grey - so wish me luck, I'll post as soon as I can.

-

Here it is from the rear - a prime candidate for a photo-etched part later on (are you listening Hasegawa?) That's it for the time being - more sanding on that glue oozed seam - then its painting - yipeee!

-

Here's the back side - you can see the bevel at the rear to make the brake appear thinner - I did the same thing with the VF-1 brake if you choose to display it open.

-

Here it is with the holes finished, I used a slightly larger bit to finish them off more as a reamer to finish the sides. I am glad that I did not thin the piece down in the beginning - it would be too fragile. The holes are small enough that the edges showing do not bother me as much. Please take care at the two last corners, as the holes are really close to the end corners of the brake.