-

Posts

2061 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Anasazi37

-

And it will be a TWE item only available inside Japan or through a proxy service

-

A gunpod hug may or may not have happened at one point. My wife thinks that it's adorable. She wanted to use it as a body pillow. I had to pry it out of her hands to get it back into its protective plastic bag. Yes, you'll receive a shipping email. It will be in Japanese. It's not easy to use the tracking link they provide, but the courier they use is reliable. Your order should show up at the forwarding service within a day or two.

-

Bummer that it sold out so fast. I snagged one the first time around. I still rate it as the most ridiculous and most fun Macross item that I've ever purchased.

-

I *do* have 3D printers and would love to make one myself, but @bzwacks hasn't let us know yet if he'll make the files available at some point. A lot of work went into the design and I would understand if he wants this to be a one-off creation. I'd also be very sad...but would understand.

-

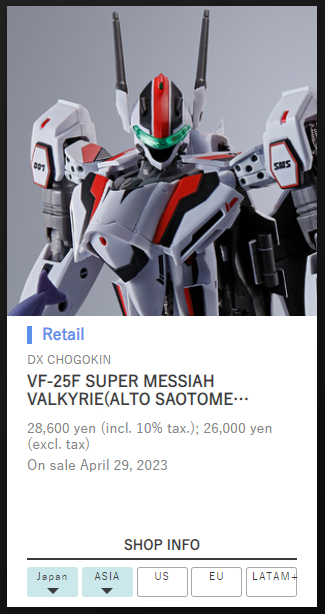

Grabbed this from the Tamashii Nations site. It normally loads in English for me, auto-translated from Japanese on Bandai's end. Looks like they recently changed how the site works, though, because when it loaded tonight only the WWM releases showed up. Pro tip: just above the language selection button is a small greyed-out region selection button and you have to select Japan for everything to show up. Turns out that when you select English, the site assumes that you don't care about anything sold outside of the US. Bad assumption on their part.

-

Theoretically, by the end of this month

-

You have a gift for extreme understatement

-

Indeed he did. I have one, currently unbuilt, and it takes up an entire storage tub in my hobby room. Also weighs a ton because it's solid resin except for the cannons, which are PVC pipes.

-

I'm passing on this one. Saving my hobby funds for something new instead of yet another reissue. Looks good, but can't justify it.

-

My plush gunpod is the weirdest and most fun Macross item that I've ever purchased

-

You and me both. One of the fun parts of living in New Mexico....

-

Or, if Bandai truly wants to troll Macross collectors, they'll just include the 011 markings with the VF-1A and tell us to fend for ourselves on the secondary market. What I think is (hopefully) more likely is a reissue of the Super/Strike Parts set along with the 011 markings being included with a VF-1A release. Sure, that means you now have to compete for two POs, and possibly both are TWE items that require you to buy through a proxy, but at least it's...something. A combo set would be nice.

-

Why Macross merchandises (toys) are relatively expensive?

Anasazi37 replied to Vintage Fanboy's topic in Toys

It's unfortunately been that way since the Armored Parts set for it was announced in 2019. Bandai had been hinting that a PO for the set might happen soon, so I took a chance and bought a new 31S on Mandarake for about $250, thinking I would pair it with the armor. The PO was announced a few days later and the 31S price on the secondary market instantly shot up to about $450. The price for the DX VF-1J Hikaru was similarly high for a long time. It only started to come down when the GBP combo set was released. Why pay $450 for just the 1J when you could get it (with some improvements) and GBP armor for $150 less? If Bandai ever reissues the Kairos, still arguably the most highly-priced, recently-produced Macross toy on the secondary market, the value of the original release would likely come back down to a reasonable level. -

I'm VERY happy to see that you're working on Daedalus and Prometheus options for the arms. For me, the DRYL-only arms are the one truly disappointing thing about the Yamato and Arcadia releases. I'm a much bigger fan of SDFM compared to DYRL and have always wanted a high-quality TV version of the SDF-1.

-

Why Macross merchandises (toys) are relatively expensive?

Anasazi37 replied to Vintage Fanboy's topic in Toys

Another thing to consider is that the fan base for Macross is likely a lot smaller than for other franchises, like Gundam. Smaller fan base means smaller production runs, generally resulting in higher prices because the cost of design and manufacturing can't be spread out over the sale of a large number of units. I'm only guessing here, but Bandai probably makes at least an order of magnitude or two more Gundam units than Macross units every year. And Arcadia is a small operation that caters to fans, so higher prices come with the territory. -

Well...since it's a non-canon valk, I guess that's the best they can do....

-

...and that's why I ended up designing and building my own high resolution laser scanner. You know, for "scientific research" and whatnot.

-

Red kite symbol should be on the left wing and pointing forward, so yes, they're on the wrong sides. Since all of the wings are detachable with HMR, it's an easy mistake to make.

-

That is coming together so nicely. As a professional photogrammetrist, I can say with confidence that most camera modeling software is crap. If they'd actually get the math right, the distortion you're talking about shouldn't be an issue--especially if you're tying together a large number of overlapping images of the same object taken from different perspectives to build a 3D representation. With that said, if the top portions of the guns are the only problem areas, that's great news.

-

I've given up on AJ for POs. For the past year I've consistently seen Macross items go from unavailable to third party sellers instantly. No chance at all to place an order at MSRP. I even tried using a VPN so it would look like I was shopping from inside Japan, thinking AJ was restricting item visibility by IP address. Same outcome. Maybe there are some scalpers with hyper-efficient bots targeting AJ now?

-

Looking good!

-

I was thinking a bit more selfishly...you know, in case you decide to make your files available to folks with resin printers.... I completely understand about the smell. I've gone to great lengths to minimize it in my house. Created a tighter seal where the cover meets the base, run two charcoal filter air purifiers inside the enclosure during printing, run a larger purifier in the space I use to clean and cure parts. And still my wife occasionally complains about the smell. I don't blame her.

-

We might see a Millia Q-Rau, but we don't even have a standard one yet. The Destroid Monster doesn't change into anything else. It just sits there, looking very impressive. Yamato and Bandai both produced transforming Koenig Monsters, but not at this scale (although the Bandai might be close). Once you start collecting HMR, it's really hard to stop. They are just the right size and price point. Even the harder-to-find ones generally aren't insanely expensive on the secondary market.

-

Would you be open to making two versions of the antenna? A resin printer could likely handle the finer detail of the original, but I can definitely see why you'd need to beef it up a bit for PLA printing.