-

Posts

3530 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by captain america

-

I realize we're talking about transforming motorcycles here, and left realism in the rear view mirror, but I just... Why does the pilot's helmet have a crash bar right in the pilot's line of vision?!? Shameless plug: there are ways to design a helmet that offers impact/crash protection without obscuring visibility... if only they'd try a lil' harder.

- 13234 replies

-

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

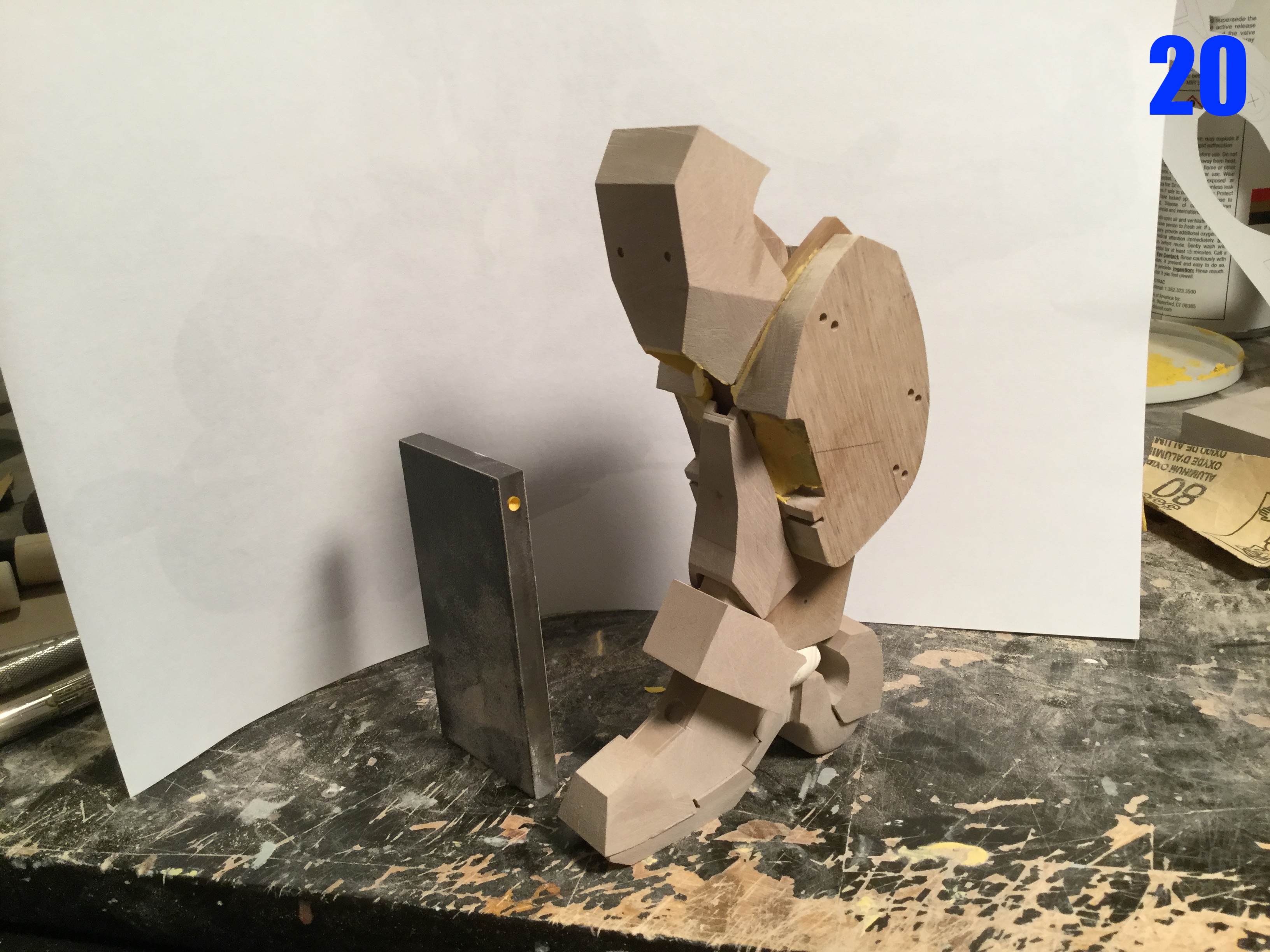

I've done something "interesting" with the foot on this figure, because of the need for good overall mobility of the soldier, in spite of him/her being on stilts! I've made the toe of the boot separate, which will then be hinged. Then, I will mold the sole in rubber to allow it to flex without compromising the aesthetics, just like a real steel-toe boot. -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

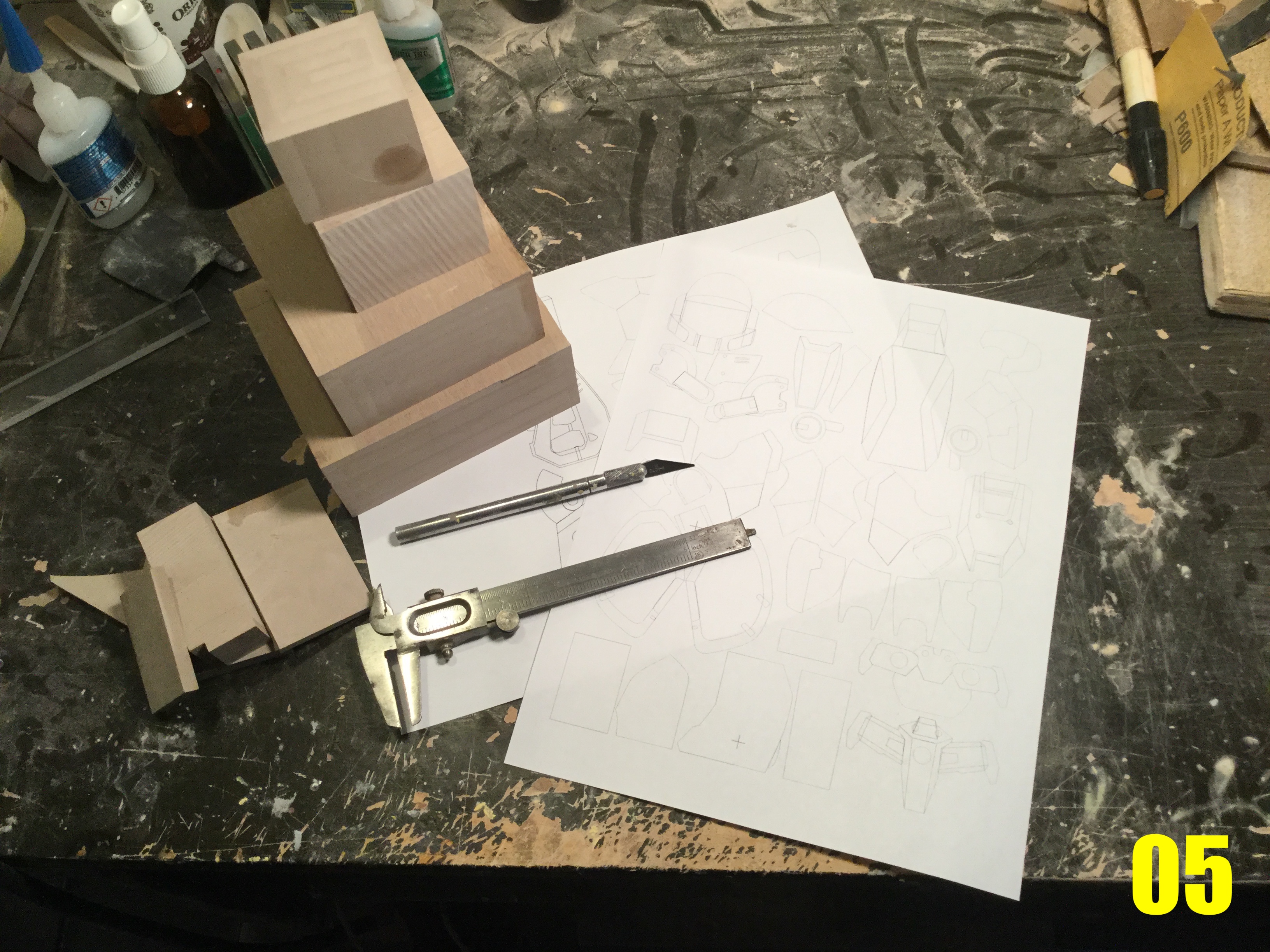

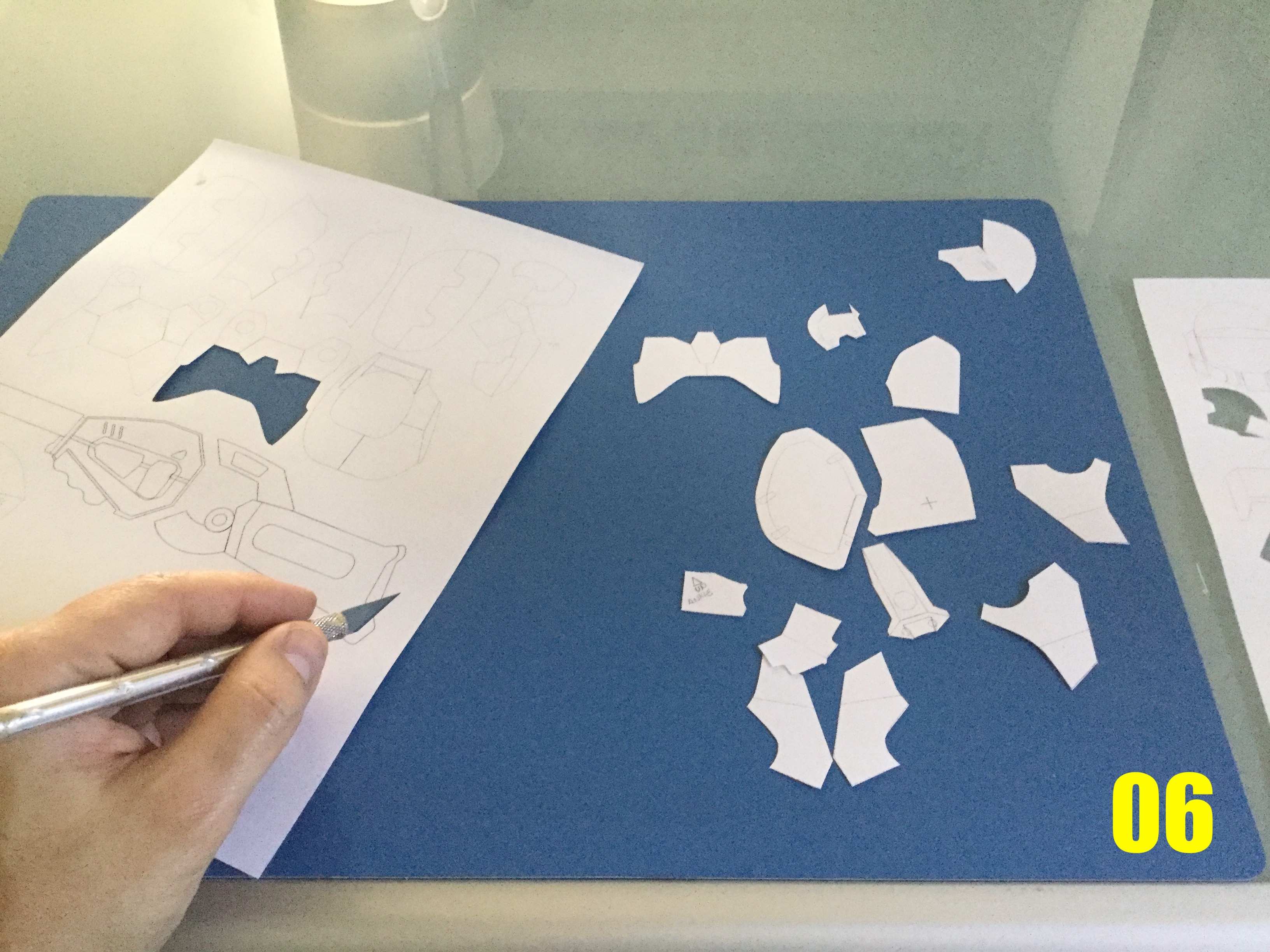

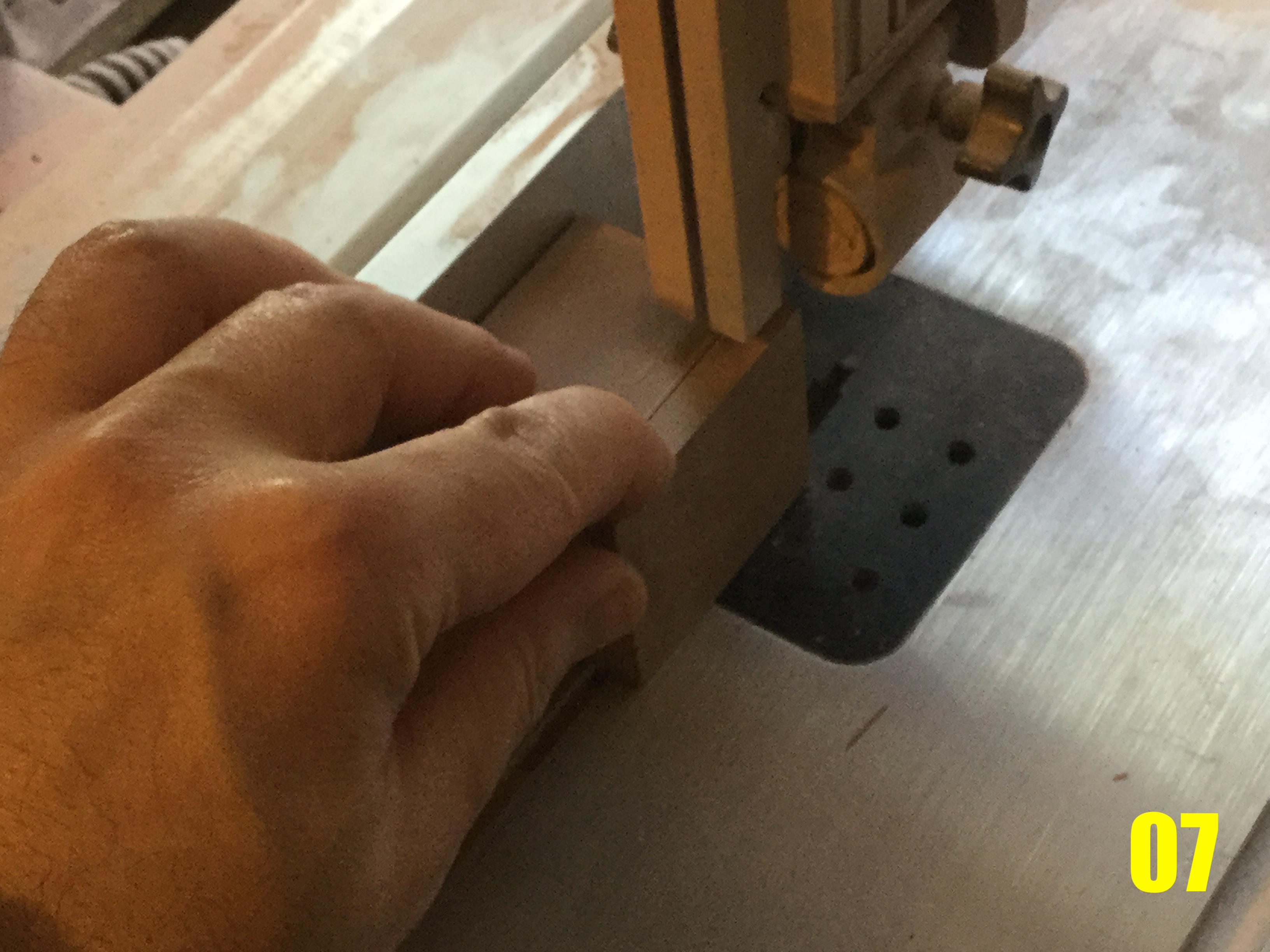

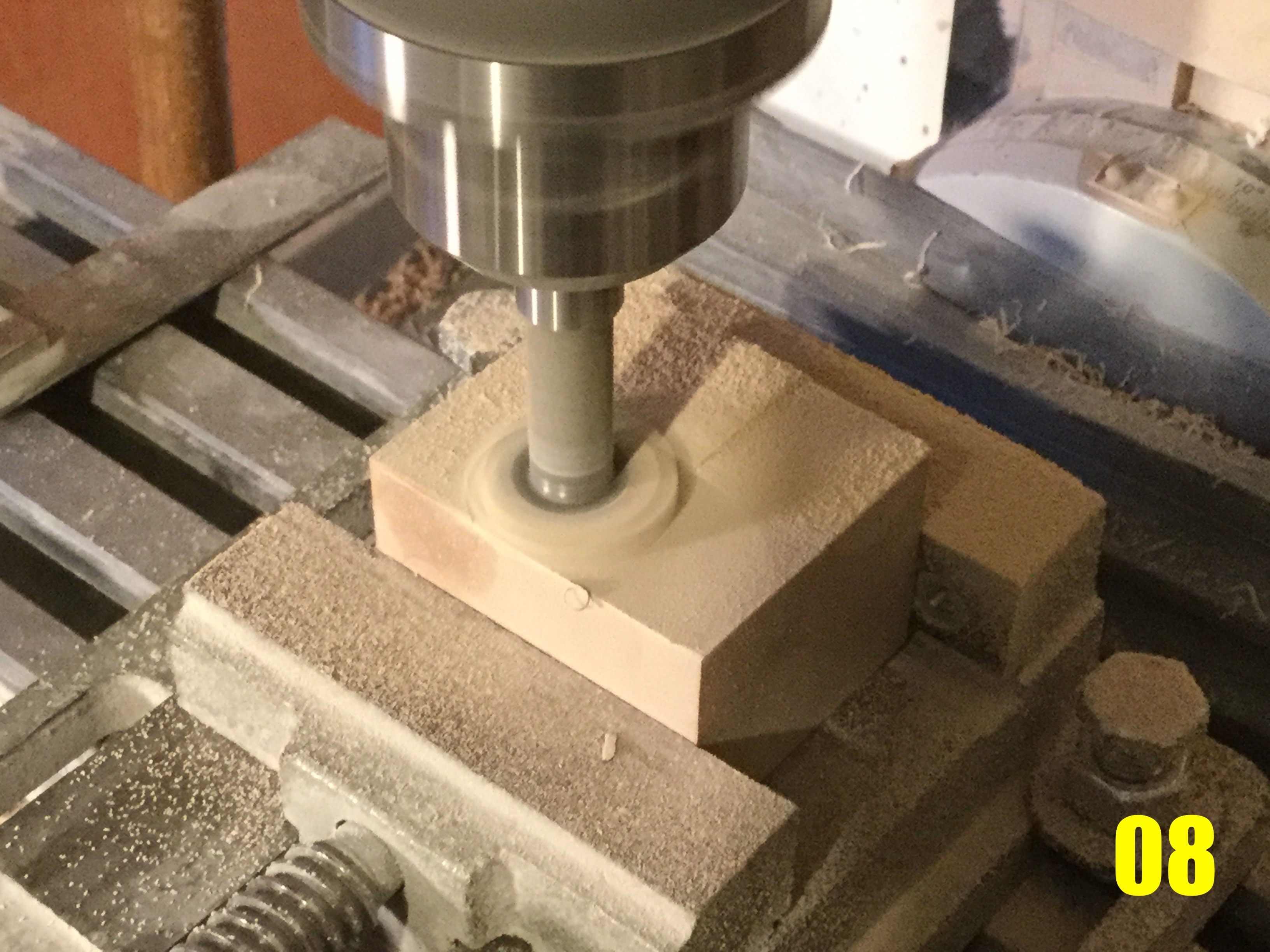

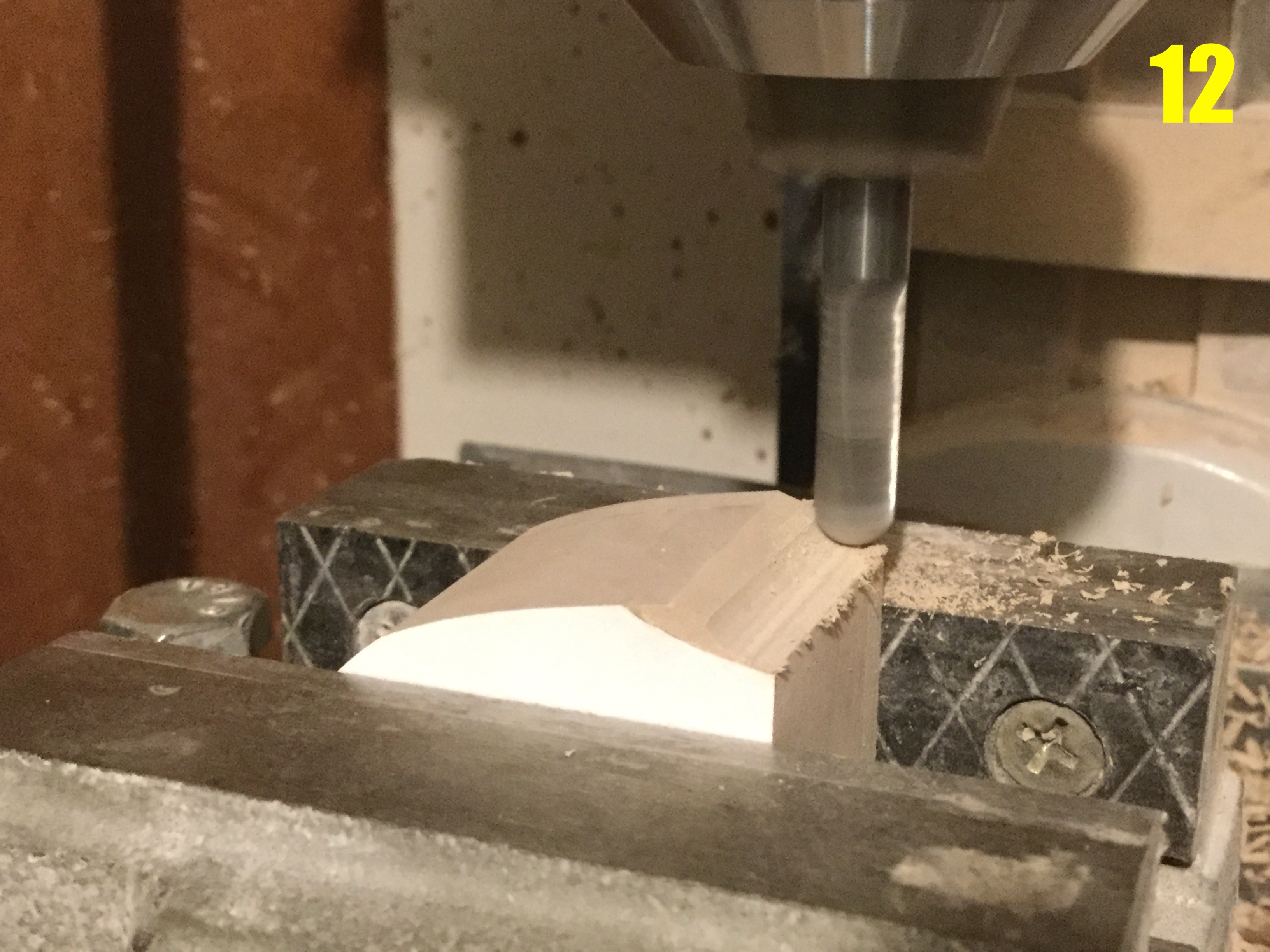

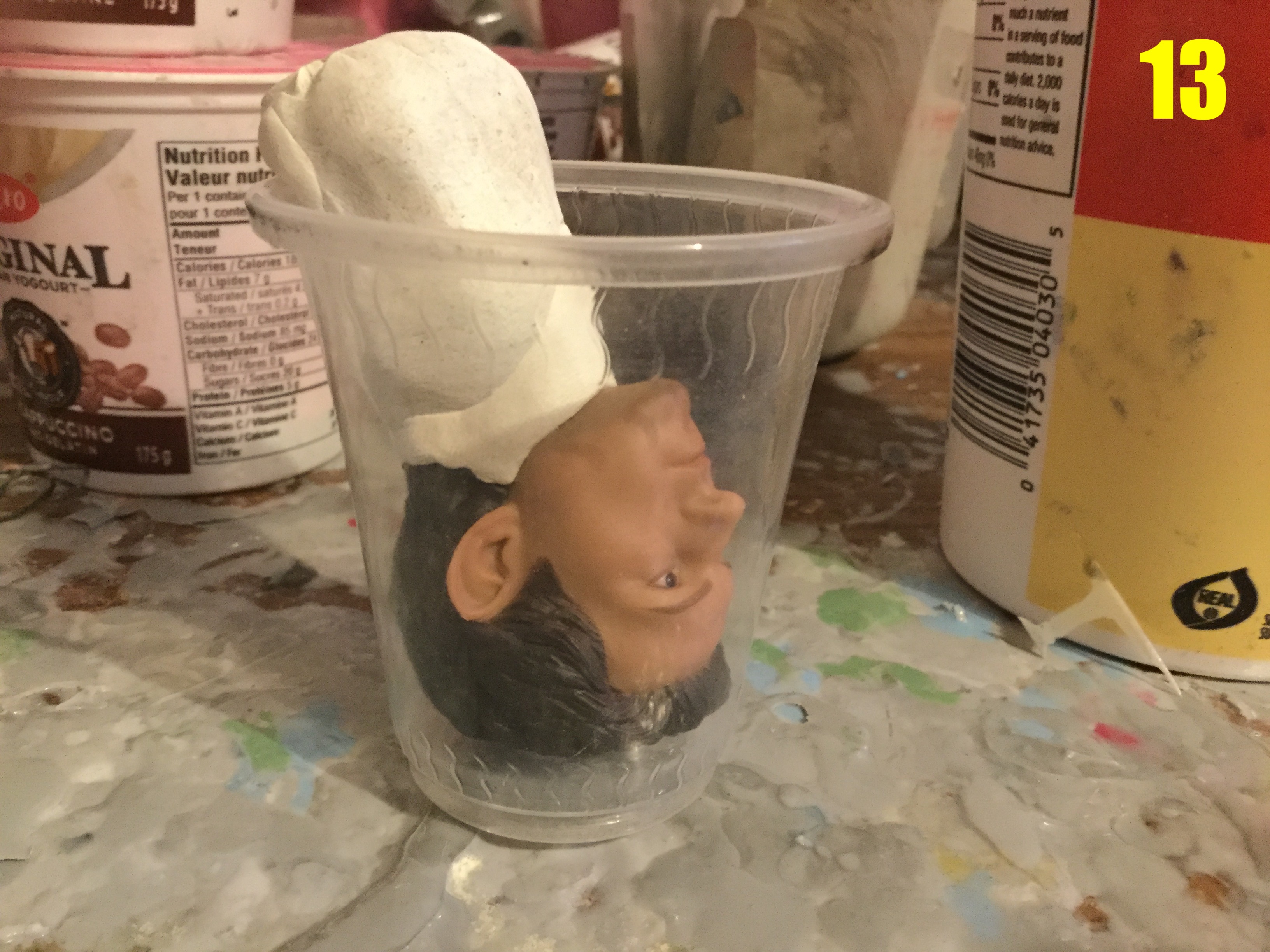

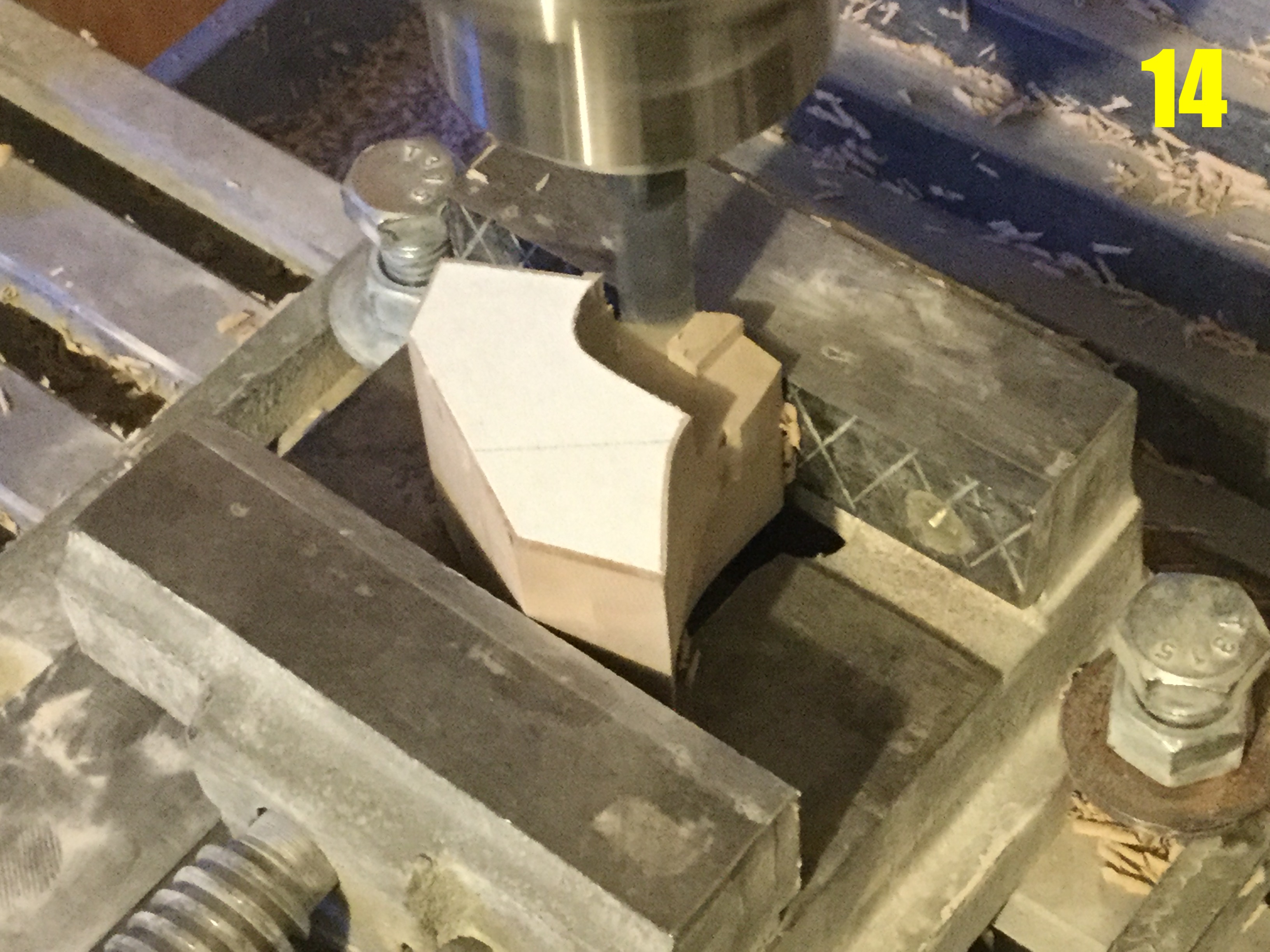

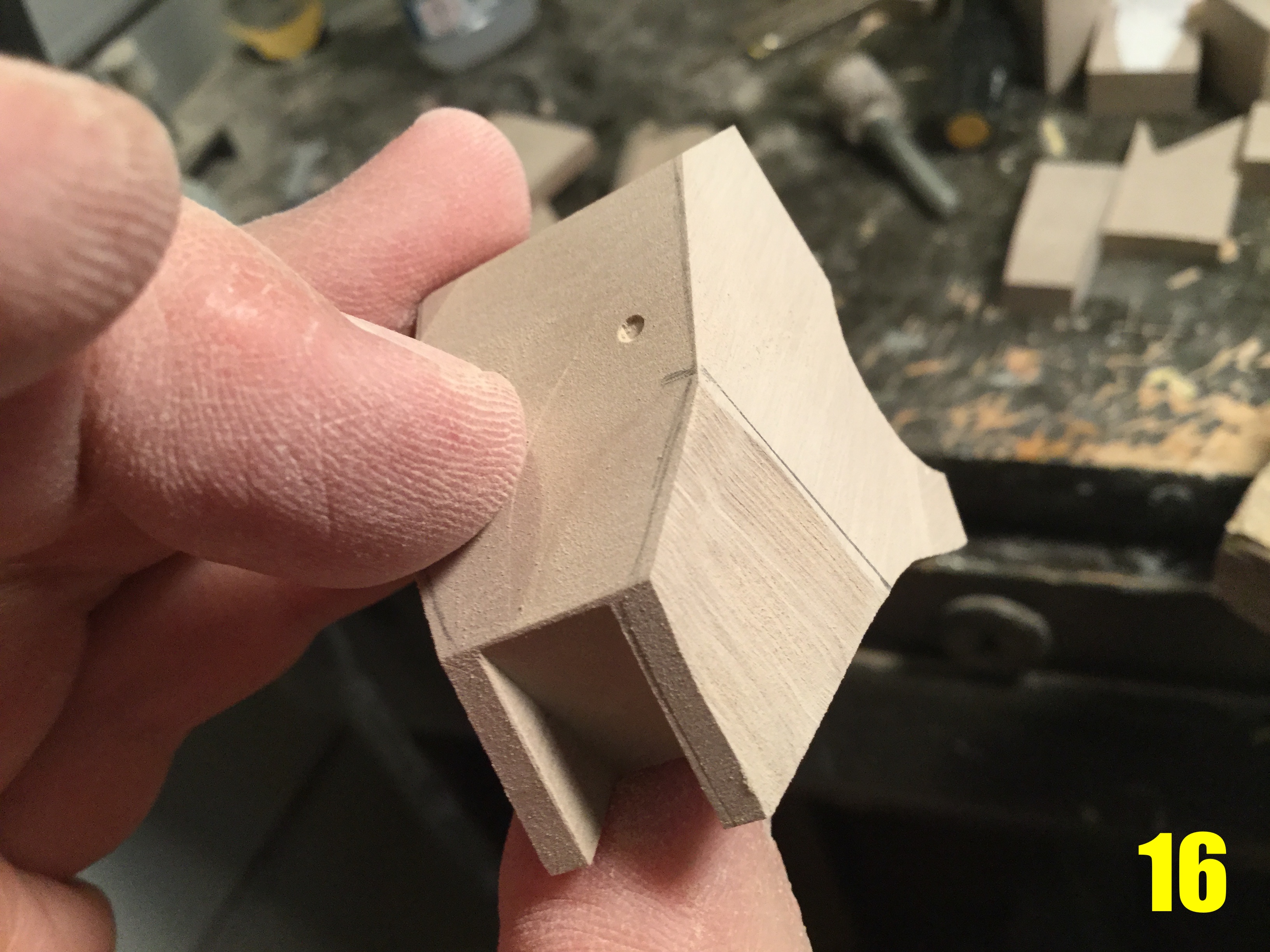

1/6 Motocycle Freak Scratchbuild Project Captain's Log: Thursday, November 10, 2022. Construction goes forth at a break-neck speed. Thanks to the time I invested in the diagrams earlier, I was able to begin the building process with confidence. Pic 05 shows the customary basics from which each mode is birthed: some pieces of modelling board, and printed diagras to be used as cutting templates. Pic 06: the first order of business involves cutting out the templates I need for certain parts. I avoid cutting them all at once, otherwise I'll lose them in the process of preparing the carving blocks. Pic 07: to avoid wasting material, I measure the rough size of the parts needed, and trim the blocks accordingly. This actually saves time too, because I don't need to spend extra time removing excess material from the blocks in the sculpting process. Pic 08: the surface of the block left by the saw blade is rough, so each new cut part goes under the face end mill to be smoothed out. The large cutting area of this tool is also a big time-saver. Pic 09: some of the major components are now ready to be trimmed. This is phase one, and most parts only require one template, but some of the more complex pieces will require a secondary template. I'm thinking specifically of the multi-component chest armor. Pic 10: in this initial stage, as much of the excess material is removed with the band saw. I go the extra mile here, because it produces less dust and saves time. Pic 11: here's a bench sander I don't use nearly often enough! This comes in handy for convex curvatures, provided the curve isn't too tight. Pic 12: once the part has been sufficiently trimmed, it goes to the milling machine, where more precise operations are performed. Pic 13: here I'm preparing to make a mold of Mr. Holland's head, so that I can get a face inside the visor of the helmet. The mold setup is crude, but works perfectly. Pic 14: while that mold cures, it's back to the milling machine I go. This is the outer knee armor assembly. You may not have noticed, but in Aramaki-san's original artwork (pic 14B), the knee geometry is different on the inside and outside, so I need to make mirror parts. Sentinel took a more “efficient” route by making the knee identical left and right, and just inserting a different part for the inside and outside. Pic 15: that same knee part is then given a quick bit of sanding in the right places, and chamfer lines are added with a pencil... Pic 16: then comes the grinding tool. I almost always need about ½ mm of material, which I will then remove with manual sanding for better control. Pic 17: on the left, the lower boot structure and the knee modules on the right, undergoing a quick putty repair. Pic 18: this is the upper body armor plate which covers the back, and is one of those parts which requires more than one template. Because it will be a crude C-shape, careful removal of the innards is needed, and I have to perform some unusual cutting with the band saw. Pic 19: so far, this is what the foot looks like. Pic 20: a crude mockup of the lower leg. This part was absurdly complicated to make, but it came out great so far. Pics 21 and 22 show the helmet coming along nicely! The 3D printed visor fits like a glove, and is being kept in its raw form the time being. I'm still adjusting the position of the face, and will then create the necessary molding around the perimeter. The face itself will be separate, so you'll have the option to put a different one in there to avoid clone syndrome. That's it for this week—stay tuned for another exciting update next time!! -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

Pre-orders are now half filled. -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

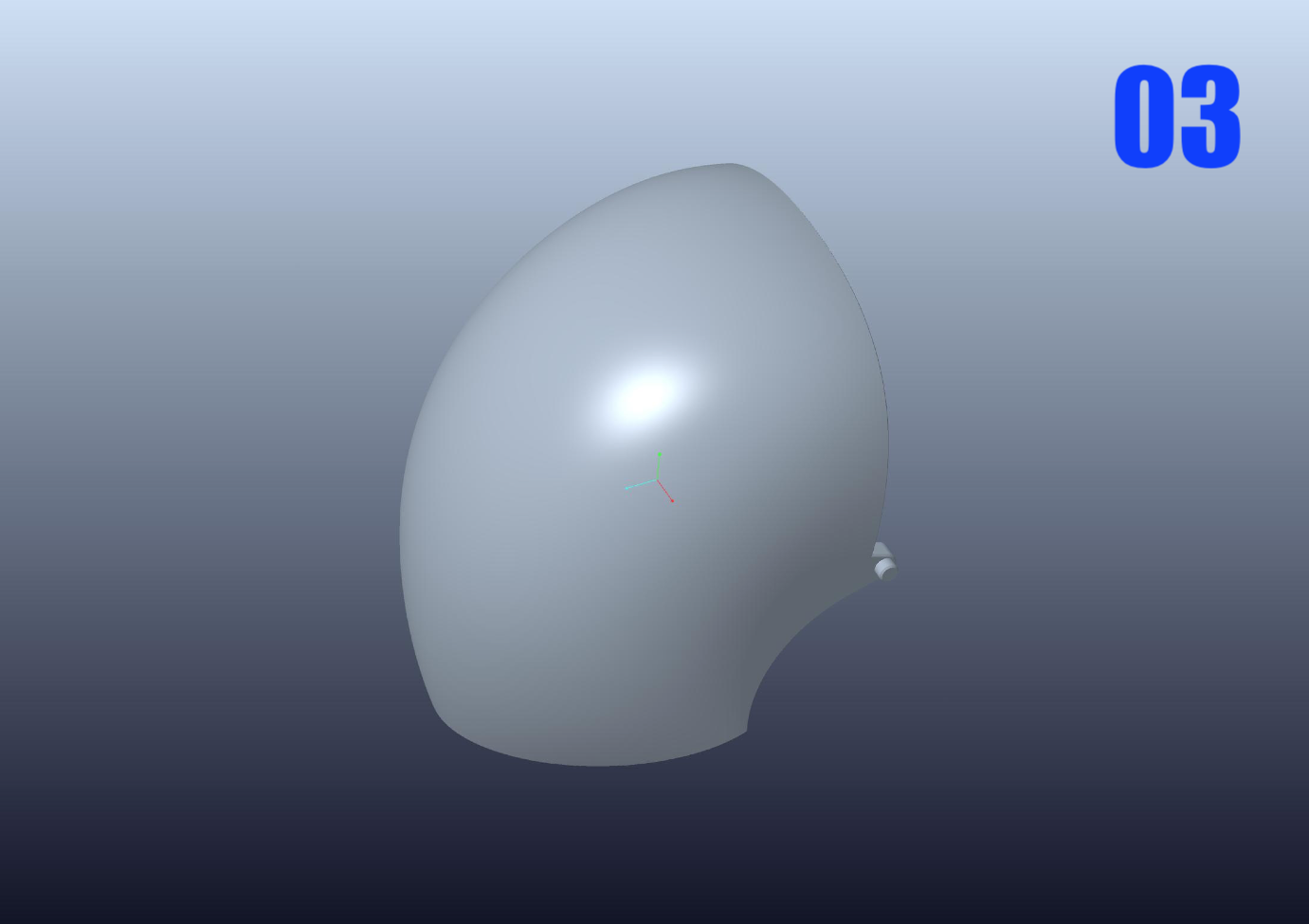

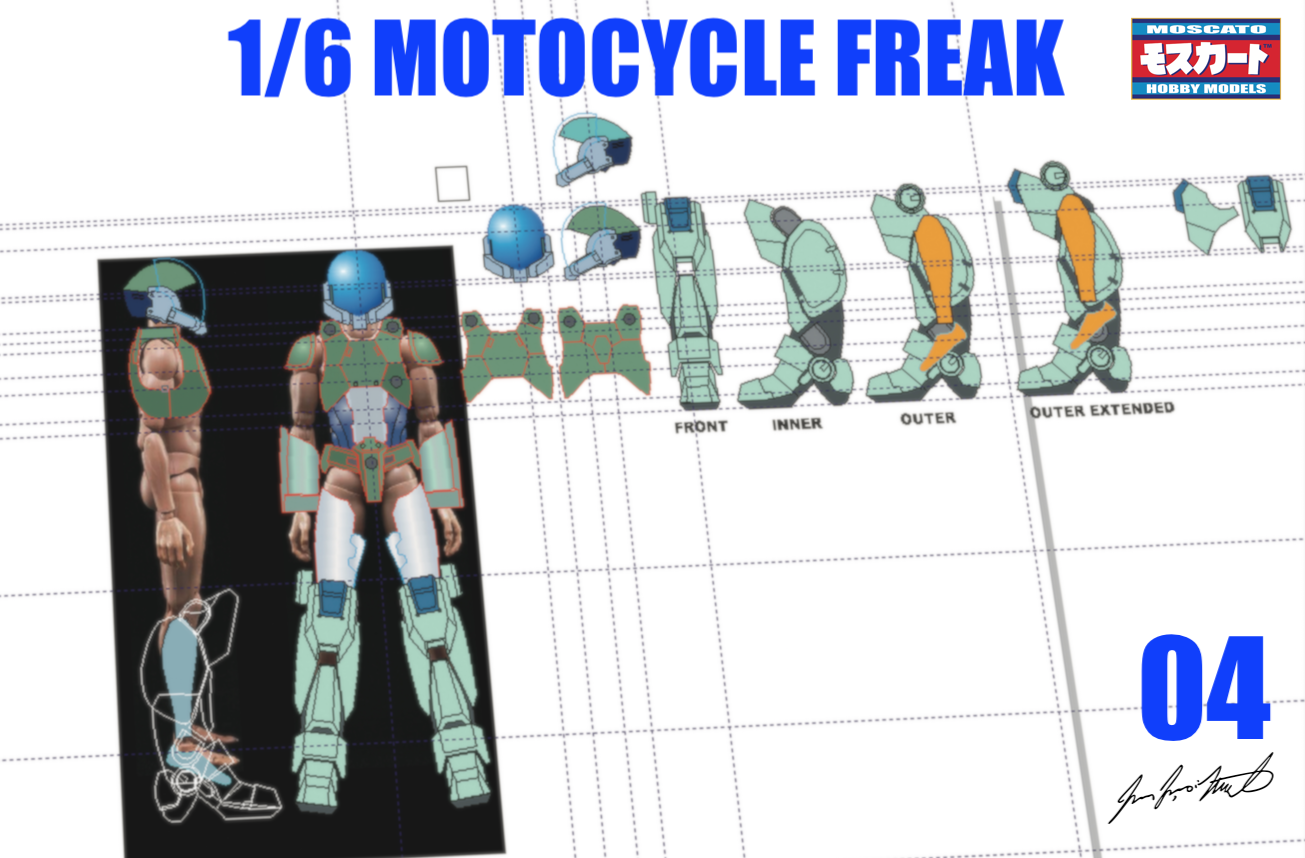

Captain's log: Friday, November 4th, 2022 I've been secretly churning out technical drawings for this new project for the last few days. I've decided to work directly from Aramaki-chan's MOSPEADA COMPLETE ART WORKS cover illustration, and as such I was confronted with quite a few discrepancies between it and the actual Sentinel 1/12 figure. While the latter is still very nice, it cuts quite a few corners on detail. As such, this 1/6 version will not be a purely upscaled figure, but a much more authentic and accurate three-dimensional rendering of that artwork. Also, because the 1/12 Sentinel figure took some, er—creative liberties with human anatomy, there will be some other, subtle, but very important alterations to this 1/6 model. Let's begin by looking at pic 01: on the left, the Sentinel figure with battle armor. On the right, a 1/12 Body-Kun figure. These are both in the same scale, with the major joints of both figures lining-up almost identically. If I scale-up the Body-Kun, it produces a man who would be roughly 171cm, so a bit on the short side. As best as I can discern, the pilot's feet do not extend all the way down into the armor boots, but more on that later. By contrast, let's look at pic 02. This is an MX02-A figure with an aftermarket head, which at full size would stand a hair over 177cm. It wasn't as easy as doubling the Sentinel figure dimensions, so I worked from scratch to create armor adapted specifically to this figure and its body proportions. As stated above, based on what I've gleaned by watching the original series, building the kits and examining the line-art, the pilot's feet only come down to roughly ankle level in the armored boot, with the boot foot being a prosthetic of sorts. Aside from giving the soldier an impressive appearance, I do believe this boot concept offers some notable advantages: the most obvious being protection from mines or other buried explosives. From a pure model standpoint, this will make the figure extremely tall, exceeding 13 inches (32cm) in height, and that's without the boot extension that happens in Armor mode! One of the first orders of business was designing a helmet and visor, with special emphasis on the latter. I want the visor to be as good and optically clear as possible, so I enlisted our very own Macrossworld member Sergio D (mechaninac) to help me with creating something that has just the right shape, and he does not disappoint! Pic 03 shows the almost complete rendering of the part, which will then be printed and cast in optically clear resin. Pic 04 shows the results of my drafting, which is still a work in progress. Here you can clearly see how the pilot's foot would fit inside the boot. While the MX02-A allows you to pop the feet off the figure for easier mounting, I still wanted to design something as realistically as possible, and take all those tolerances into consideration. Though there's still quite a bit of tweaking left to do, I might be able to start cutting as early as next Friday—stay tuned! -

It can transform into a pile of parts if you hit something hard enough at speed! 😆

- 13234 replies

-

- 2

-

-

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

Hey y'all! I have already begun drafting the parts, so I can hit the ground running. I'll have a first update on Friday... oh, and a third of the pre-orders are already in--keep it up! -

*Shrug* The more I see of Genesis Breakers, the more my disappointment grows. I like how Aramaki modernized the classic Mospeada design, and the way Sentinel made the transformation work--despite questionable materials choices in the figure, they still get a massive thumbs-up from me. Everything beyond that just looks like trash. They took a good, functional design and just added junk to make everything look busy as a means to compensate for the fact that they have no creativity. Often times, less is more. 😑

- 13234 replies

-

- 1

-

-

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

-

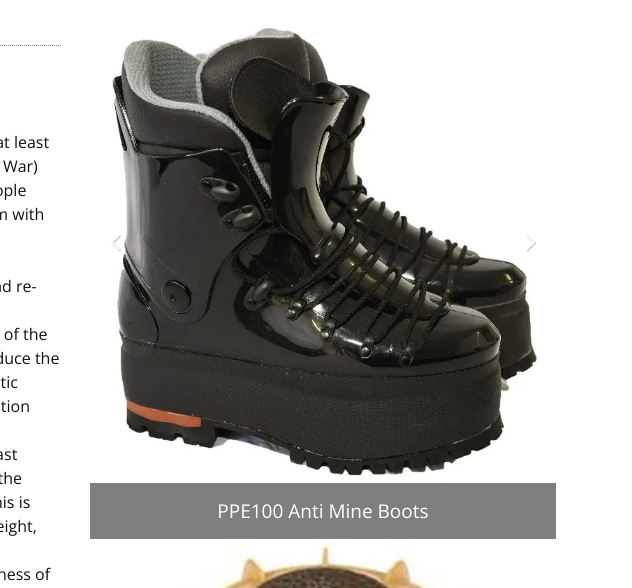

It may not be as dumb as it looks. While the older design with big feet was aesthetically pleasing in its own 80s way, big feet really do hamper mobility. If you've ever tried walking with snowshoes, or oversized boots, you quickly realize how easy it is to trip over your own feet, so in that sense, smaller is preferred: better dexterity, quicker, more precise movement The other interesting aspect of the MOSPEADA boot design is that in either version, the driver's foot doesn't extend all the way down into the foot of the boot: the latter is itself almost a prosthetic that elevates the wearer and affords him/her important protection from mines or other types of IEDs. Like a better version of these.

- 13234 replies

-

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

Looks like the project will go ahead, because demand is surprisingly high. Will open the pre-orders October 28th. -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

Yes, they sure will. Added, thank you! -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

The female armor would be taylor designed around a female body figure. We're already half way there, way to go!! -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

q1: correct. q2: If there's enough demand for the female armor, I'd definitely make it. -

Medicom/Hot Toys and all 1/6 scale figures

captain america replied to EXO's topic in Anime or Science Fiction

For those who may be interested -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

I'll see if I can provide some useful Mr. Color paint colors if the project goes ahead. You can also eyeball the colors on the 1/12 Sentinel figues. I will also correct some of the detail shortcomings from the Sentinel figure, so it would be more faithful to the MOSPEADA COMPLETE ARTWORKS cover illustration. -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

That's the one! You'd need that figure and also a set of 1/6 tights in the color of your choice. I'll provide several MB logos to denote different ranks so that the builder will have more build options. -

1/6 MOSPEADA Rider Project Proposal

captain america replied to captain america's topic in Anime or Science Fiction

-

New Moscato Hobby Models project proposal: 1/6 Motocycle Freak. The kit would consist of all the body armor for the rider, designed to fit a MX02-A figure. The head will come with a separate, realistic (non-anime) removable face and posable visor. Abdomen parts would be molded in flexible material for better posing mobility. Decal markings will be included, as well as gloved hands. The pre-order (first 30 kits) will include the rifle/stock/barrel, which will be extra once the pre-orders are filled. Please note that the MX02-A figure body is not included. You'll need that and the onesie of your preferred color to complete the build. Price: $310 Canadian + shipping. The project will only go ahead if I can fill all 30 spots. Please post 'WANT' only if you're serious about making a purchase for this. Any post that doesn't meet the previous criteria will not be counted. So what say you?

-

1/48 SOUTHERN CROSS BIOROID PART II

captain america replied to captain america's topic in Anime or Science Fiction

*Heavy breathing intensifies* 😛- 150 replies

-

- southern cross

- robotech

-

(and 4 more)

Tagged with:

-

The Unlicensed Third Party Transformers Thread

captain america replied to slaginpit's topic in Anime or Science Fiction

What I'd like to know... is this figure bare plastic, or is it painted with a matte finish?- 9275 replies

-

- fans toys

- mastermind creations

- (and 19 more)

-

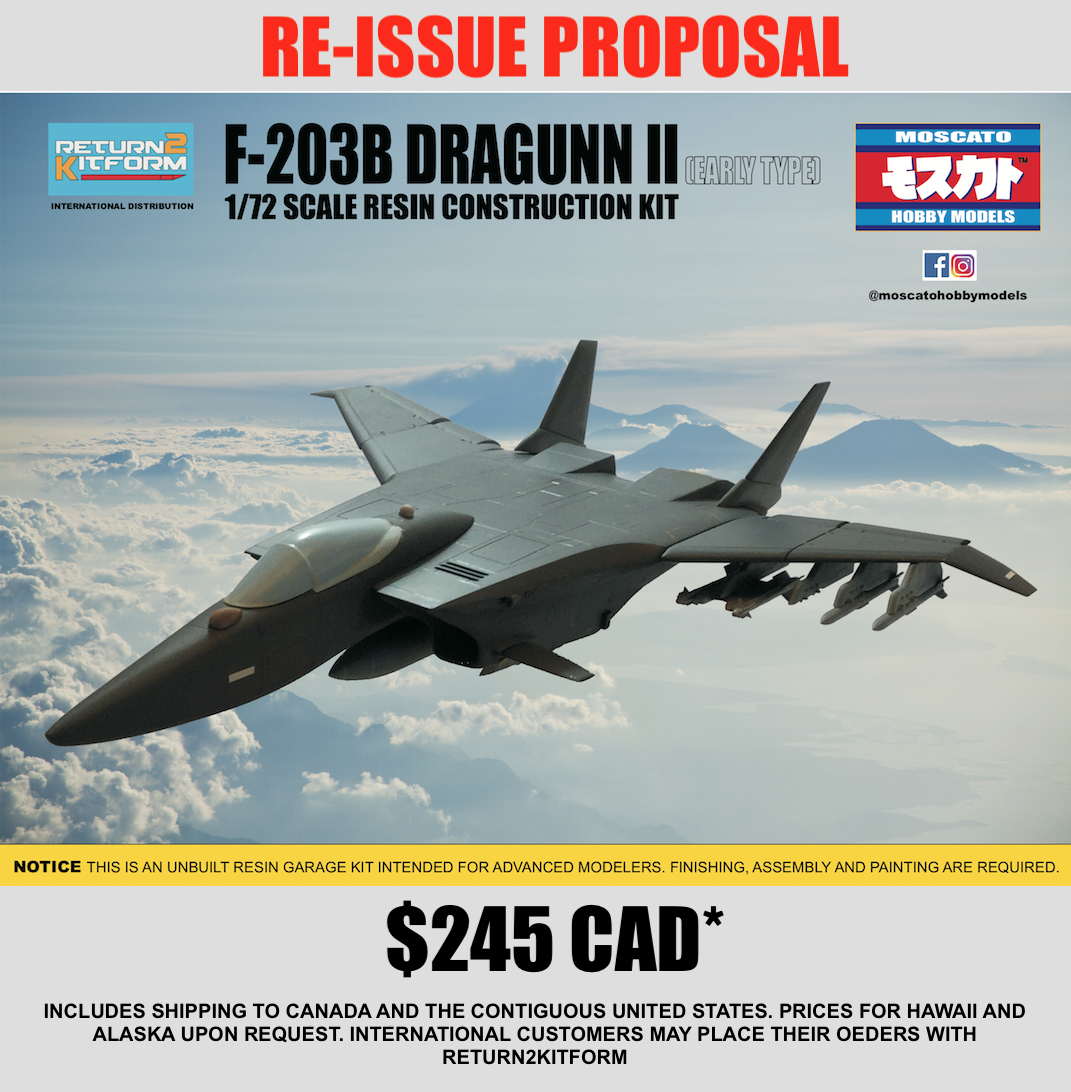

1/72 F203 Dragon II Kit Proposal --Moscato Hobby

captain america replied to captain america's topic in Model kits

Seeing as how Wave covered the VF-4, I don't see the point in offering a resin kit of it. They dropped the ball on the clumsy surface details, but I don't think that warrants paying 50% more to solve. Frankly, I'd rather offer an F-203E ground attack, 2 seater variant with bomb payload. -

1/72 F203 Dragon II Kit Proposal --Moscato Hobby

captain america replied to captain america's topic in Model kits

Re-issue is scrubbed. Maybe in a few years. -

Great build! That kit brings back a lot of memories, and I enjoy seeing people bring my kits to life. We need 1/48 Destroids!

-

1/72 F203 Dragon II Kit Proposal --Moscato Hobby

captain america replied to captain america's topic in Model kits