-

Posts

921 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Chas

-

I'm not so sure if they would sell. Sure there are people who would buy them, but you are forgetting that the majority of Hasegawa's customer base are not anime fans. They are aircraft/model enthusiasts. Hase. has already risked alienating their customer base by even producing the Macross line. To start producing tranforming anime kits a-la Bandai could actually drive away customers who were interested in the company for its traditional model lines and want nothing to do with transforming 'toys' (as thsoe kinds of kits are seen by these people). There are alot of model companies that Hase. is in competiton with in the traditional model market, and the last thing they want to do is give there customers any reason to buy from the competition. Now, I know what your thinking. "Not many people, who like Hase. kits, would be stopped from buying a kit that they really want simply because they didn't like another type model that the company produced". But this is an issue of reputation. Hasegawa has a particular reputation that has been hard won. To do anything that could damage that reputation is not something that they will take lightly. And as you have seen Modlers have strong feelings when it comes to the line that seperates models from toys. I for one don't think that Hasegawa is willing to cross that line anytime soon, Some people, I'm sure think they already have and are probably not happy about it. Thatl being said the only way I can see for Hasegawa to do this (if indeed they have any desire to) is to create a subsidiary company with a different name for their transforming Anime kits. -Much like the way car companies have different makes for their different vehicle lines. Anyway that's my two cents worth. Oh, and for the record I wouldn't buy a 'transformation add on kit' or a transforming Hase. kit, I prefer the dedicated modes as they will ALWAYS LOOK BETTER THAN ANY TRANSFORMING KIT, and my kits are built and displayed (usually I pose them how I want them and then fix that pose with a little CA.

-

Well I think your best bet for sculpting classes would be your local Community College, as has already been said. But if you are serious about learning how to make moulds and cast models try this Smooth On I've never taken it. I don't know how much it costs. But it sounds like the best introduction to mould makinng/casting you could ever want. If you decide against the course you might find other useful info on that site, so spend some tim and look around. Good luck. Charles.

-

If Sk Were To Make One Final Macross Series,

Chas replied to Phalanx's topic in Movies and TV Series

If wishes were horses beggars would ride. -

Sticky fingers hunh? Oh right! you mean from casting.

-

It may sound dauntinng, but it all that is needed is some simple skills, some practise, and confidence. You might want ask around and see what kinnd of materials folks around here use when working with ABS -(i.e. what kind of paint? what kind of primer? what grits of sandpaper? what to use for clear coating/ etc.). Also try to work out the order inwhich you will be progressing through the project, you might want to write it down. If your not sure just ask the guys here. Once you've done this, then just take it step by step. The secret to this kind of stuff (at least what I've learned from models) is PLAN YOUR WORK THEN WORK YOUR PLAN As before Good Luck! P. S. It's a real good idea to practise on stuff that's not too dear to you while your learning. But you seem to know that already Charles.

-

No prob. I live to serve

-

Ah. . . guys . . . ummm. . . Check this thread Doh!

-

Well I've never worked on toys (ABS), I'm a model guy, but I would think it is better to strip the enitre thing and start from scratch. Otherwise you will run into the problem of matching the colour and finish of the Factory that produced the toy, not an easy task for a beginner (or anyone I'd imagine). Before you do any stripping make sure you have the stickers/decals you will need for the project, as well as the paint of course! and you might want to consult someone (Kurt?) about how/which parts need to be disassembled, 'cus I don't think you need to take it completely apart to paint it - just the main sub assemblies. But as I said I'm a model guy and I don't even have a 1/48 so I'm not sure about that last part.

-

No Prob lem. I'm working on one at the moment myself. Good luck!

-

Try this Hase gerwalk If that doesn't work search the How to build/Custom forum for 'Haseagawa gerwalk conversion' Make sure you have selected 'Show All' in the display field at the bottom.

-

Check the main site. Magazines>Hobby Japan> Oct. 2002. You'll find some very self explanitory pics and some instructions in Japanese. Also use the search function and check the forums there are a few threads on various conversions of these.

-

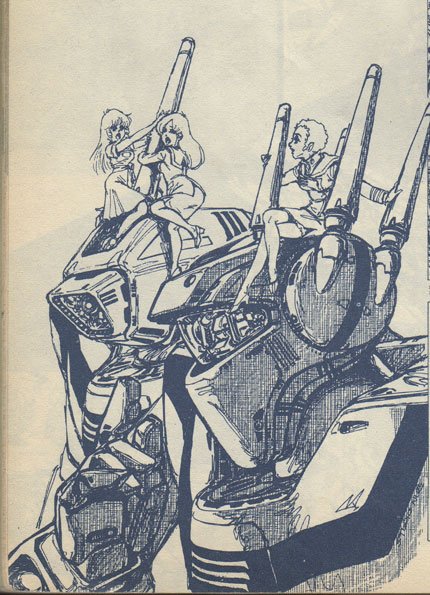

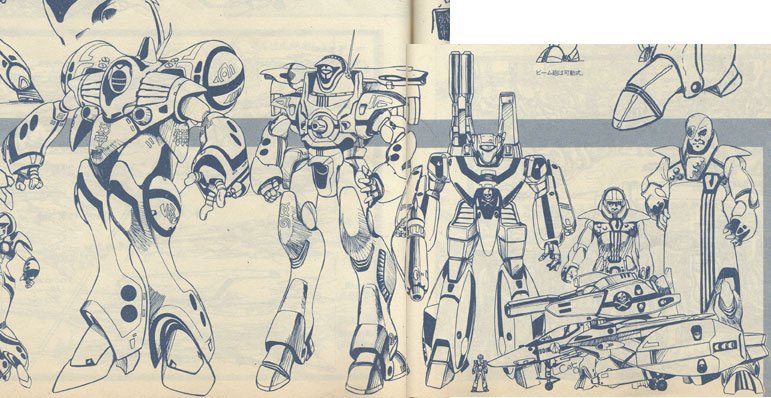

Pretty cool stuff there. So it seems to me that he was saying something like :in the producfion design phase the Meltrandi design aesthetic was made to resemble that of the SDF-1 to emphasize that they were a different race from the Zents. Also I think there may have been something about the SDF-1 being a Meltran ship. But that is all speculation because I don't understand a word of Japanese. Still a cool thing to see though.

-

Pretty cool stuff there. So it seems to me that he was saying something like :in the producfion design phase the Meltrandi design aesthetic was made to resemble that of the SDF-1 to emphasize that they were a different race from the Zents. Also I think there may have been something about the SDF-1 being a Meltran ship. But that is all speculation because I don't understand a word of Japanese. Still a cool thing to see though. Thanks Solscud007.

-

No prob jardann. VFX OMFG! That has got to be the most awesome paint job I've ever seen. That technique with the tape is just terrific!. Is there a write up to go along with those pics! Cus I for one would love to read it. There is a lot there that I could learn from. Are the panel lines on the Primary hull scribed or just painted? I couldn't decide. Awesome, just awesome!

-

-

Hey jardann Nice job! which kit is that? Looks like it's pretty small, good work on the detail.

-

So so essentially that's Tamiya putty and laquer thinner, then. I had hoped I could avoid the stonger solvents but I guess I'll give it a try.

-

Well have a look at this. I know it's from DYRL and the mecha in the film is different from that seen inn the TV series but I think it should help anyway.

-

O.K. Quick question. what do I use to thin Tamiya putty (basic) I was thinking of using isopropyl alchohol, but I thought before I tired I'd ask here. So what do you floks use?

-

If the bushes you have are not stiff enough try trimming them so that the bristles are shorter. This will give you a 'stiffer' feel. Try that before you spend more cash on new brushes. Save the cash for more kits.

-

Checking in at 34.

-

There ya go! Seriously though, those are some beautifull customs. Anyone know if that 1/72 Hase. GBP custom is scratch or a moded GBP kit from years gone by?

-

Why so glum chum? Just think, this means that it is possible to do this stuff yourself! It's good news! I mean we all know it's way more fun to mod kits than to build 'em straight out of the box. This is just something to shoot for. Let it inspire you not discourage you! Turn that frown upside down!

-

I think your argument is flawed in a number of places. But let me just deal with what I think is the major one. You state that What you fail to consider here is the fact that the magazinnes in question are discussing the newest, most recent, releases in Macross merchandise and not neccessarily those most popular with model builders. (better to fill your mag. with pics of the latest, newest stuff than yet more customs of models that either everyone has, or that are no longer available. Plus as a magazine you have tokeep certain people (your advertisers) happy.) You see, I suspect that, the reason these mags. have articles about customizing toys is becaue while it is a legitimate hobbby that is closely associated with model building it is also a way for them to talk about the newly released Macross merchandise. Newer is sexier in the competitive world of magazines. If you actually look closely at the magazines you'll see that the most recent issues, on the whole, deal with the merchandise as it's been released. And there have been a lot more new toy releases than model releases. The latest large scale legit. Macross model realeses have been the Hase. kits and of those the Mac zero stuff and the Mags in question deal with them in that order. Just wait untill the Hase. and wave VF-0 battroids hit the stores. Then have a look and see what the mags have featured. It is flawed to use a commercial endeavor, such as a magazine, to judge what is happenning in a social, cultural activity without taking into consideration the forces and pressures that control and constrict that commercial endeavour. The next time you want to make a sweeping judgement about what is happening in a cultural activity read some sociology texts and learn to avoid such inane, and immature pitfalls first.

-

Check my last post in this thread.here But your link is a good idea. This stuff is way better than the Tamiya polyester putty IMO.