-

Posts

4701 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

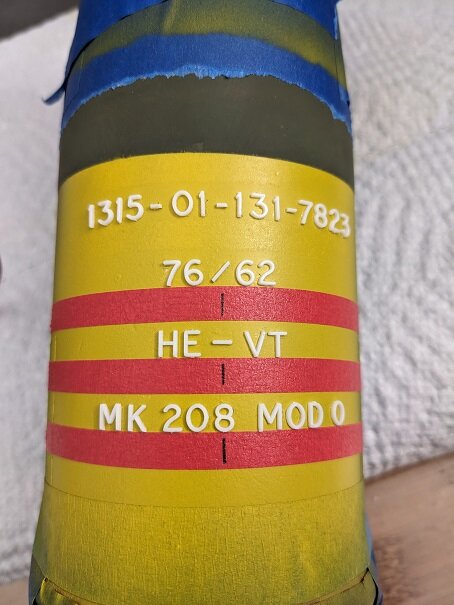

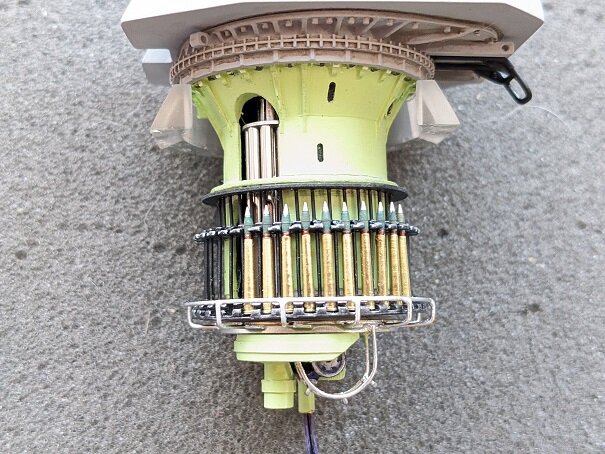

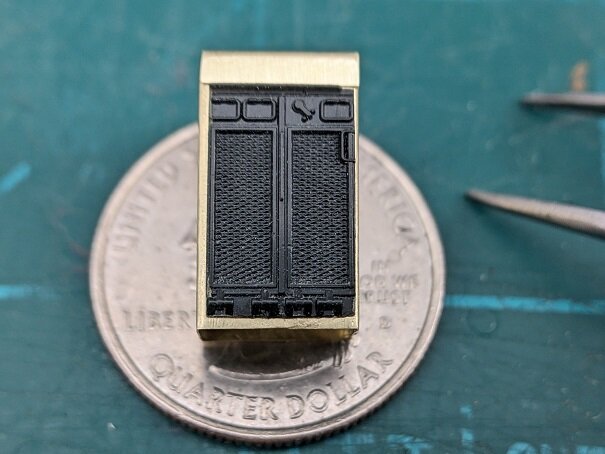

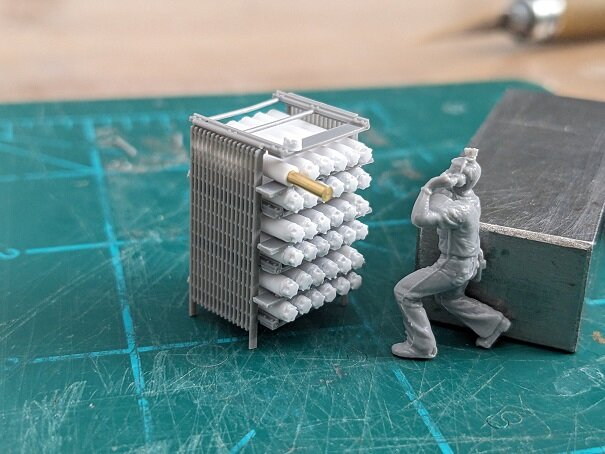

@arbit THAT looks like Isamu!!! Smooth too (no pun intended 😁)! @Chas You did "The Ole' Girl" justice! Great weathering on it too! @nightmareB4macross Your "fixes" look much better than stock. Having it transform closer to the canon version will be worth all the effort! @Rock That Tomcat is looking SWEET! I actually know one of the pilots that fairied those over there. Interesting stories😎. @Mr Jones Good to see you back on the boards! PE is FUN to work with (note sarcasm in voice). It makes a difference though. FINALLY making some progress on the 1/1 - 1/72 Oto Melara canon diorama. It's weird working on the "real thing" and a model with it in there. First off, the 1/72 complete rounds (brass propellant case with the projectile as one ready-to-fire piece). Projectiles were turned on a Dremmel to mark the copper driving band (orange Sharpie) and then painted OD green. They were then glued into the brass cartridges with G-S Hypo Cement. The brass was coated with thinned nail polish (you can see a scratch in one). And one of the gunners that carries one. The brass rod are how the figures will attach to the base (better than just glue). And another gun crew member taking the rounds out of the storage rack. The rack is ready to go too. And ten rounds loaded into the rotating magazine of the canon's turret. All of the gun mechanisms below deck are controlled through this panel on the actual gun. The model has two LEDs. One is a color changer and the other is a tea-light candle LED to flicker. All are soldered to a 1.5V "Joule Thief" board to run them. LOTS of blackout methods used to control the light leakage. And now back to the 1/1 scale 76mm resin projectile. I wanted to add the stenciling on the projectile, but had no way of making a custom stencil. I DO have Plastruct 1/4" letters though! So I reversed stenciled and used them. I used little dabs of contact cement to make them stick. You can see where the glue also masked the paint, but added to the stenciled effect. And finally starting the base coats for the gunnery crew. They all look like they had to much to drink 🤣 That's it for now. Thanks for checking in everyone! - MT

-

@pengbuzz "MECHTECH INC. FINALLY FINISHES REPLICA BOAT" - THAT - WOULD be a headline!!!🤣 Gott finish my ship! The water on the papers actually adds realism besides making them less hand-made. REAL newspapers outdoors would be subject to rain - or whatever falls from the sky in that dump of a city😁 @arbit The only thing that doesn't make Isamu look like himself is the hair hanging down in his face. Other than that, I think he looks GREAT!!! @505thAirborne Don't know if you did it yet, but if you gloss coat that model, the decals will melt into it like butter! @derex3592 And you can longer whip a pilot out of the Hasegawa ground set. The helmets and uniforms are VERY different now! SORRY! I agree with you though. - MT

-

@pengbuzz WOW! I finally made the papers (hopefully for something good, it's kinda hard to read). Your vignette looks AWWWWESOME! I don't know what you were worried about. The first head TOTALLY looks like Peter Weller! Like "Honey, I Shrunk Peter Weller" and he's wearing robot action figure clothes now! That is definitely worthy of a model show! You even got props from WM Cheng on it who worked the movie!!!👍😎 @nightmareB4macross Your Valk modifications make it look WAAaaaaaay better! It's hard to get that Chunky Monkey look out of that design, but you're making work out great! @derex3592 That Bradley is looking sharp! It's too bad it needs to be weathered for realism to cover up that clean finish! @arbit Great sculpt as always! I can't speak to proportions, but the only two things that stood out (because you asked us to look) were the belt buckle, the belt pockets(?) and the chest piece. 1). The belt buckle looks like it's a triangle pointed to the upper left hand side, vs a box as you've shown. 2). I'm not sure how big the print is intended to be, but it looks like the belt pockets, almost look like fanny packs on the side could be softened on the corners. 3). The chest piece has vents on it around the edges on the left side. It looks like you have them cut into the front of the sculpt vs on the beveled edges. The far right hand of the chest piece has an indented circle on it. It looks like you made it spherical and protruding. I hope that helps. I only found those points because you asked😁 Again, great work as always! - MT

-

@nightmareB4macross Lots-o-putty! Sanding that ABS must be a pain! Sometimes the only way to get a smooth finish on it is to wet sand. I started the Nichimo 1/200 Battleship Yamato years ago. ALL ABS. I sold it after only a few assemblies, it didn't want to cement easily or cleanly sand. If you haven't heard, the BEST glue for ABS is straight Acetone. Unfortunately, I only found that out years after selling the Yamato😕 - MT

-

@pengbuzz Looks like Robo is "Takin' out the trash!" 😁 I'm glad you didn't give up and was able to make his face work! @Chas That gunship looks nice-n-clean! I love that model (the original and Bandai versions)! I started one with folding wings. I gotta dig it out some day and finish it. Nice touch chroming the letters too. @derex3592 No snow day here😕, just a delay. Your Hornet and Bradley are looking REALLY good! @Rock I've never tried that technique before. I'll be watching what you do to see how it works out😉 It's always fun learning new things! - MT

-

Thank you everyone for the positive feedback! @neptunesurvey1 Looks like you had to get another account working. I'm glad you had more pictures to share! That thing is a printed brick! LOTS of plastic in that print. Thanks for sharing the additional COOL photos! @pengbuzz Looks like Robo made the headlines again!😁 COOL looking paper! @derex3592 That is a SMOOTH paint scheme. Are you going to dust or muddy it up (almost sad to). - MT

-

@Kurt AWESOME detailing and figures man! Those 1/35th figures look 1/12th at least and the uniform camo is spot on. You could definitely get some metal at a model contest with that baby! @pengbuzz FANTASTIC scratch building of the backdrop! Your mods to that figure are next level and also AWESOME! Like Kurt, I think you could get a trophy at a model show with that build! - MT And sorry, it took me so long to post my stuff, I missed your guys stuff😁 - MT

-

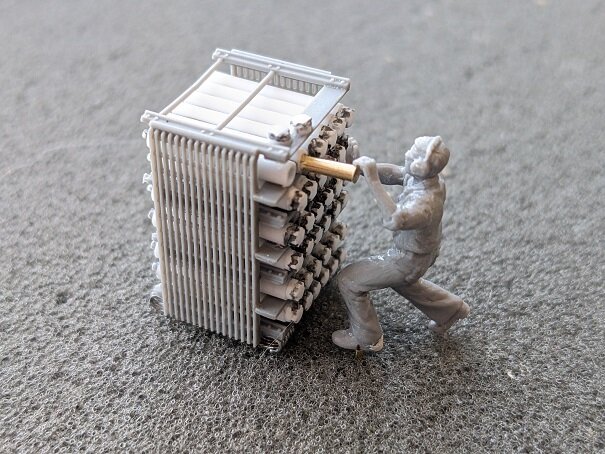

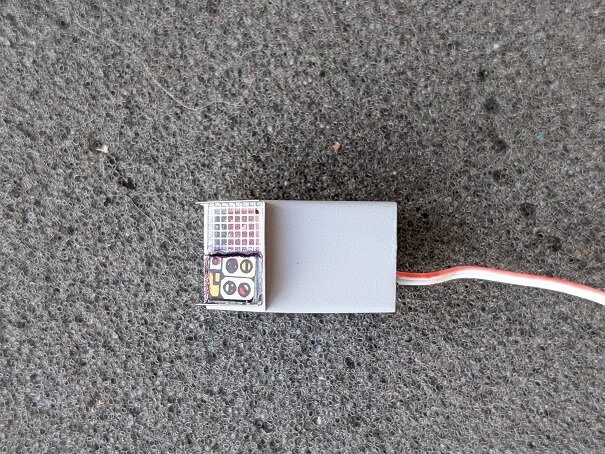

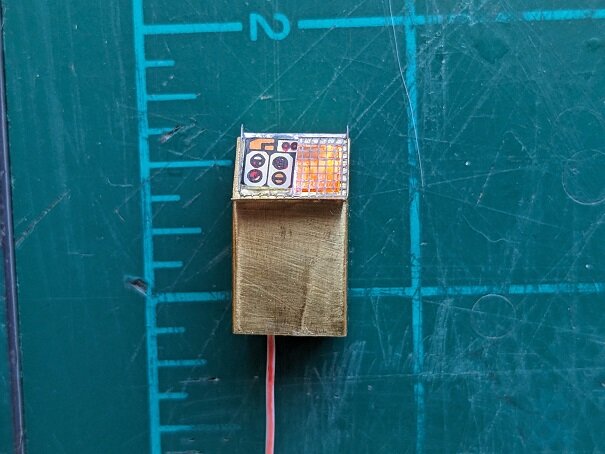

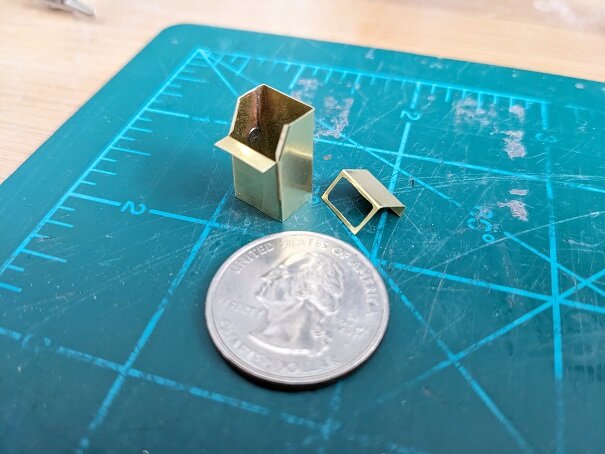

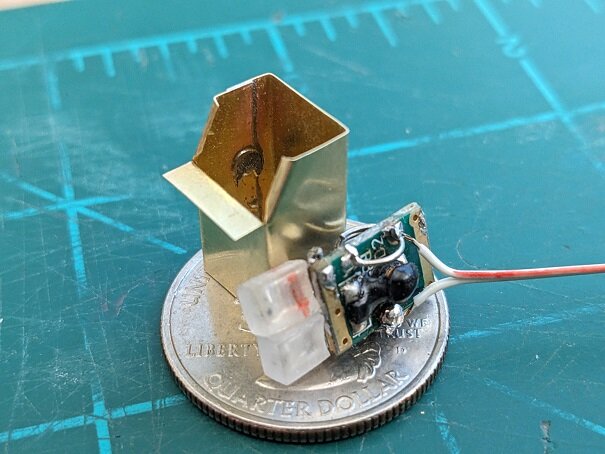

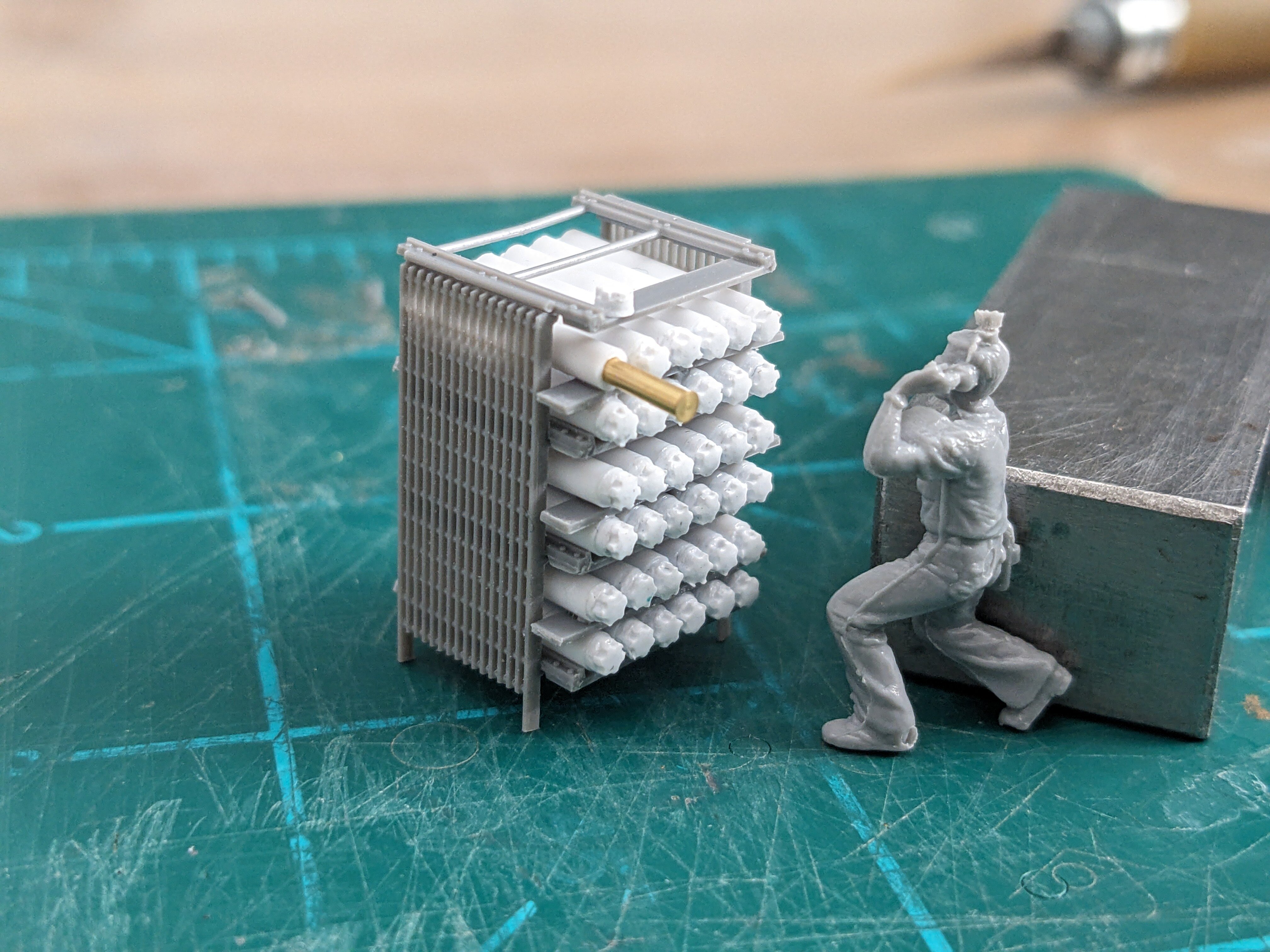

FINALLY posting some slow progress on my OTO Melara diorama build. The canon has a control panel below deck adjacent to the gun mount. I wanted to light it, so it had to shield the light and be small. That meant plastic would be bad to use to make it. That left brass as the best candidate. A smart man would have used photo etch, but I didn't have that option, so I had to use scissors and thin brass. Backside cooling screen from old tank parts. The motor only uses a single 1.5 volt cell to run and adding more batteries for lights would be a pain. So I got a flashlight circuit (A "Joule Thief") to use 1.5volts for the 3volt LEDs. One LED uses a color changing LED (the monitor) and the other uses an LED "candle" light to flicker under the buttons side of the panel. EVERYTHING got coated with nail polish lacquer to insulate it. The LOOSELY fitted control panel before painting. You may remember this from last post. Most sensitive equipment on board ship has some type of shock absorption system due to the pounding ships hulls can take. Those shock absorbers are usually simple loops of heavy cable. I tried SEVERAL ways to do this. The best resolution was THIN wires soldered (tinned) and wrapped around a couple of brass tubes. Here's the ammo rack with the loops added and a brass rod to "invisibly" attach it to the base. The figures are the 1/72nd Hasegawa ground crew HEAVILY modified to to look and pose to fit the equipment. I screwed up on the brass name plate. The guy dropping empty plastic cases will cover that up.😉 I also had to re-sculpt his face to look surprised. That's it for now. Thanks for checking in! - MT

-

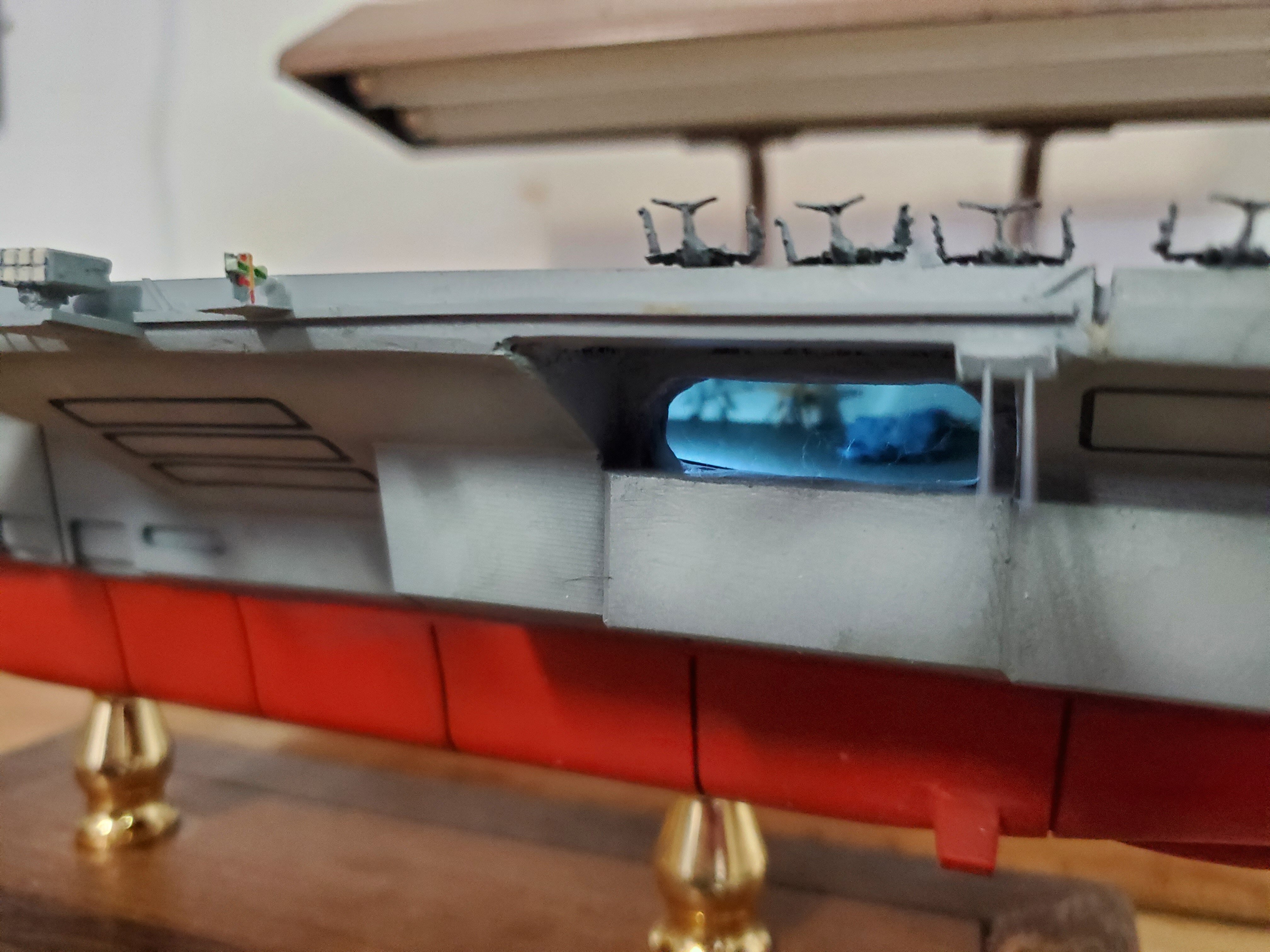

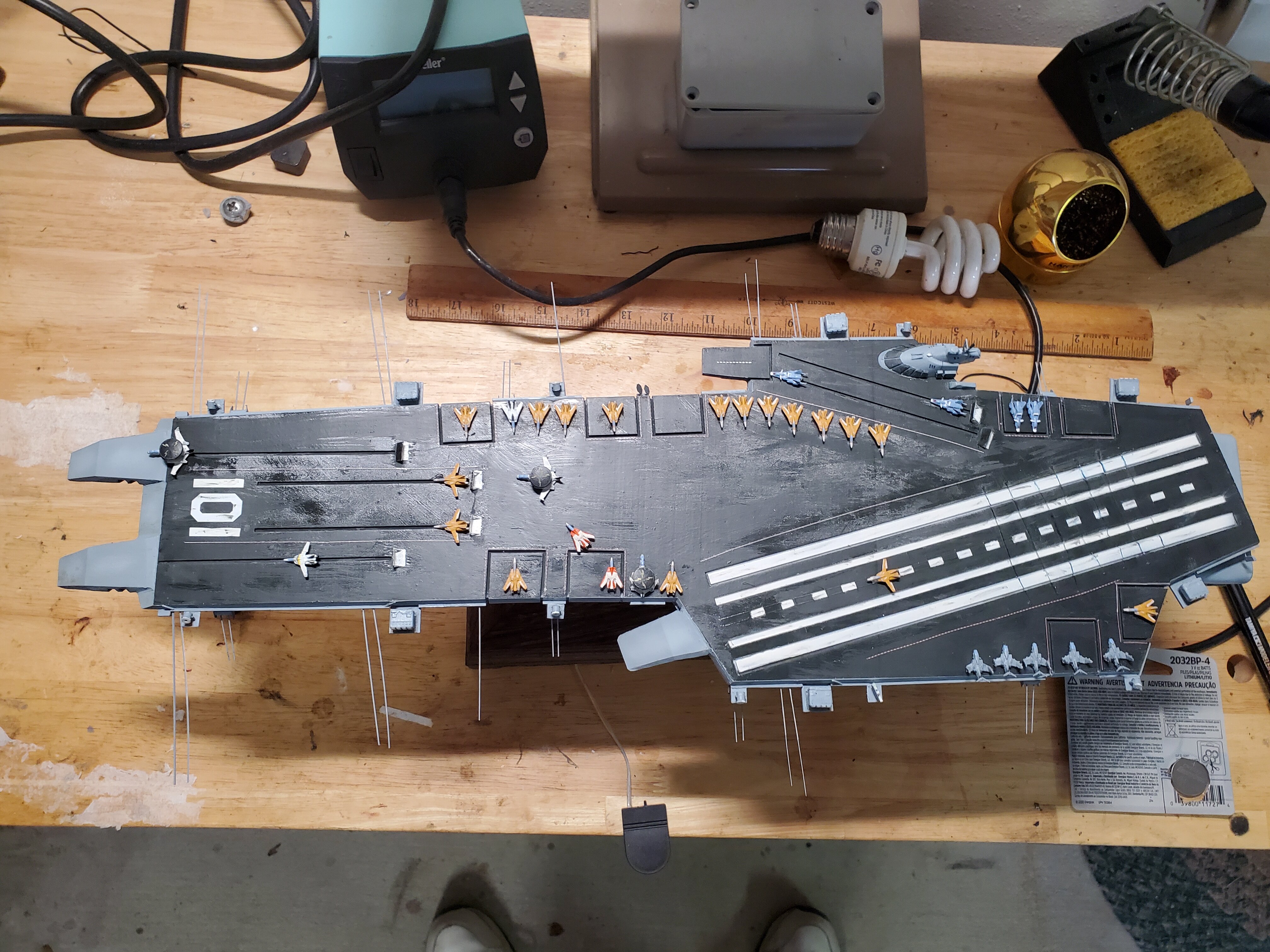

Posted on behalf of @neptunesurvey Mods, he's having problems logging into his account, and has no reply to his email. Can a mod message him and unlock his account? Thanks! These are my words, not his😎. Neptunesurvey completed this BEAUTIFUL Prometheus, build in 1/1000 scale. It took him about a year. It was a 3D print; some of you may recognize the sculpt. I'm posting full size photos so you can see all his details. We usually only see the carrier, or the aircraft. Now we get to see BOTH together. And even some RARE birds on deck too - look carefully! Even the stand helps bring it all together with class! Enjoy! If you like his work, please send @neptunesurvey your comments directly so he'll eventually see them. If you "like" it, only I get the credit for what he did. - MT

-

@electric indigo COOL!!! - MT

-

-

@pengbuzz Your Robocop mods look AWESOME! You can tell its a work of love! @505thAirborne Your '23 is looking great! Still hard to believe that plane didn't win the fighter competition. @Rock That is a cool looking cockpit. The new details look MUCH better. @Thom Your plumbing is a GREAT touch! it adds a bunch of detail that normally gets missed. - MT

-

OOoooh! 400th page of this thread (for this version). - MT

-

Looks like the elves have been busy in their workshops!😁 Merry Christmas everyone! - MT

-

@derex3592 BEAUTIFUL Bone! I don't see the decal flaws!? Looks cool fully loaded as well! That DOES look like a nice kit. @Big s Lion O🤣! That's funny! You can still paint her. Those dark shadows will mellow out with highlighting paint over it. The eyes are the difficult part! - MT

-

@Urashiman OK, the kit gets an ENORMOUS F, but you get AWESOME "A" for courage and craftsmanship!👍 Nice cleanup of flash on that thing besides the putty work. - MT

-

@Urashiman Whoo hoo! Another R/C boat! You DID take on a tough subject! But I KNOW you can do it! Anyone need an interesting theme for your F/A-18C model? Here's an idea and more photos linked. DVIDS is another good source for US military photos and video in general. Free account needed for full sized downloads. - MT https://www.dvidshub.net/image/7487368/vmfa-312-flies-armed-teeth

-

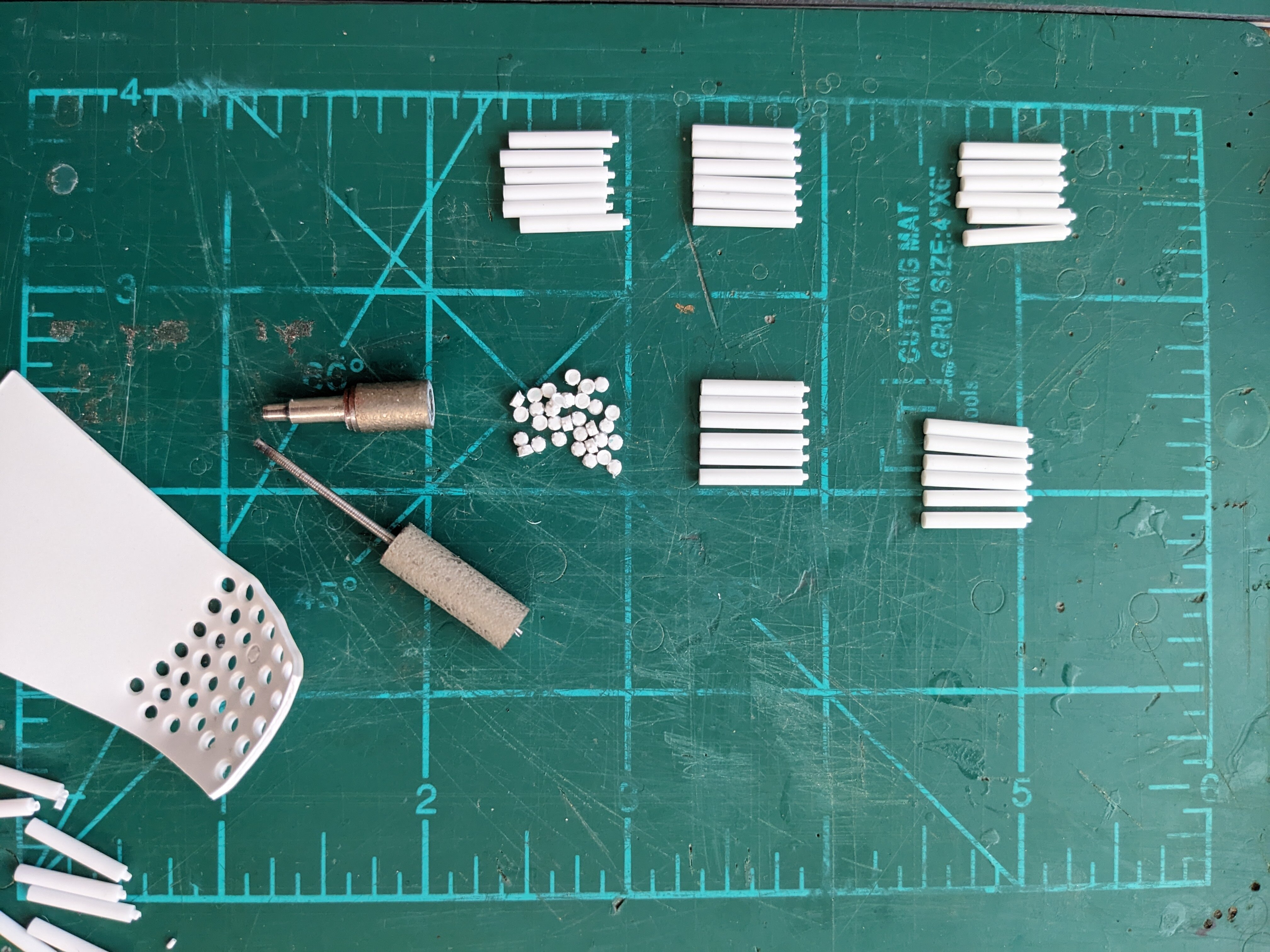

@electric indigo Those colors came out really nice! If you guys haven't seen these, Hobby Lobby has them. They make great eyes or sensors and are translucent (light shows through them). Nice price too! I've gotten a little further on the Oto Melara diorama. Polishing the shell casings using a reamer to hold them and a Dremmel tool with a buffing "wheel" (what's left of it). The projectile drive bands were "painted" using an orange fine-tipped Sharpie. Fast and furious! The individual shell carrier cases were made with styrene dowel and that punch I made from a Torx bit. The ammo shelves are made from Tichy Train Group's grating. They are FINELY molded and clean with no flash. I then "butchered" them to make this. The next step is to make the coiled cable shock absorber springs that the bottom mounts to. Also modify the Hasegawa ground crews to be ammo crews. Thanks for checking in guys! - MT

-

@Urashiman Those bubbles are inside the resin somehow. Looks like its mostly just at the bottom too!? Weird! In Europe, the floor wax is Pledge, last I heard. It MAY fill in some of the bubbles better and it has a great translucent effect to it in certain light. @Bronze Knight You're making that nightmare kit look great! Lots of parts not fitting well with that kit. Great looking, vibrant paint colors too! - MT

-

Thanks @Big s! I'll have to try it out. I'm trying to avoid the "Brock" look from Pokemon and the "Little Orphan Annie" look of just white eyes. I try to avoid using figures because of those reasons, but they need to be in this for reference of size and to show function. @derex3592 That's a COOL shot! I didn't know they putting pods on them too. That's the first I've seen of them. Probably to add optics that weren't put on the craft from the design stages. -MT

-

@SteveTheFish Your custom articulation will make that a MUCH better model for posing. The stock styrene joints just don't last. @wm cheng Your Valk cockpit and figures look fantastic! I think you'll see more detail than expected. Your "pinpoint pupil was a good idea! I'm hoping there's a GOOD tutorial on painting 1/72nd scale figures. Having "little Orphan Annie eye's" can be distracting from all the great work on the rest of the figure. I have a LOT to do in the coming months or so. Three now for my gun turret model. @Urashiman Nice and smooth prints! @derex3592 Clean coating! - MT

-

@Urashiman Your valk is looking beautiful! That is A LOT of decal work to be careful with. The details are looking great on it! Maybe dipping the canopy in Pledge floor polish will help (or whatever they call it in Europe these days). Not the bubbles, but you're next canopy. @pengbuzz Grumpy Cat looks GREAT man! You can't tell you did all that work to him - which is good! He looks like he came in the box like that. I look forward to the rest of the gang being done. @derex3592 WOW! Somebody was busy! Great looking finishes. I forgot, for the Cat's Eye, were you just trying to strip the paint off it? If so, the "LA's Totally Awesome" (Dollar Tree) is cheap, totally safe and does a great job. Tamiya's paint comes off in minutes. Enamels maybe a couple of hours depending on thickness. A scrub brush helps speed things up. You just need to clean the residue off with soap and water. - MT

-

ALL: Superglue AND Baking soda will fill just about any Grand Canyon sized gap in a model or scratch build project. Baking soda is also an AWESOME accelerator that's not toxic like those spray-on types. The baking soda also adds strength to the CA. I've made whole parts out of it 😁! @Thom That Tomcat cockpit looks BEAUTIFUL! Have you added any clear UV or epoxy resign to any of the gauges to build them up? It looks like the Sparviero is being a modeling pain as it was a real pain to the allies in the war😄 @Urashiman Your cockpit improvements are AWESOME! Hopefully the canopy can be opened on it to reveal them better. @pengbuzz First off, I'm glad your not a real orthopedic surgeon😉 HOWEVER, you're an A-W-E-S-O-M-E plastic surgeon!!! When you add Roy's 80's hair to him, his height may be just right 😁 His proportions look good. If you need more height, it would probably have to be in his torso - what a pain! Then again, there's always those clear platform shoes with goldfish in them🤣 -MT

-

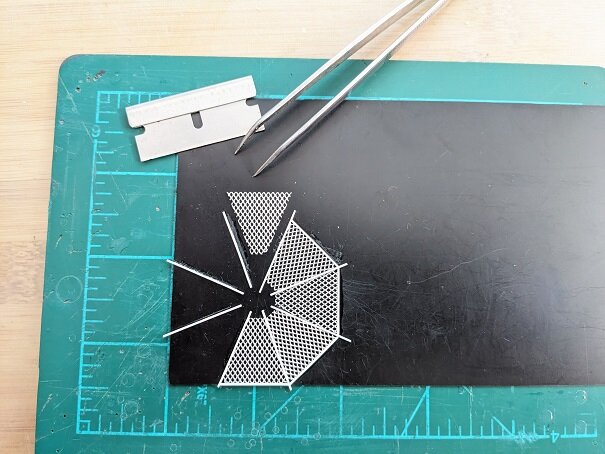

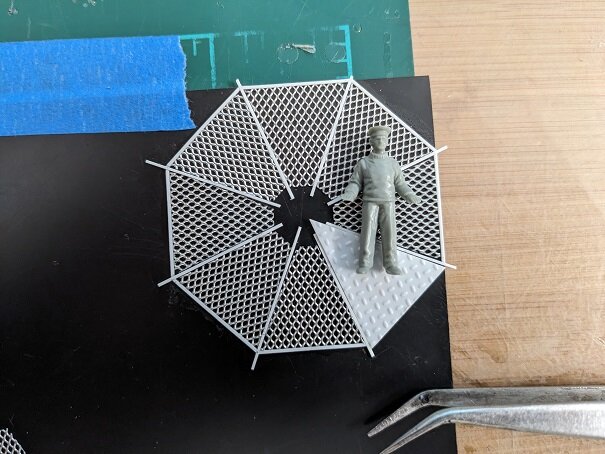

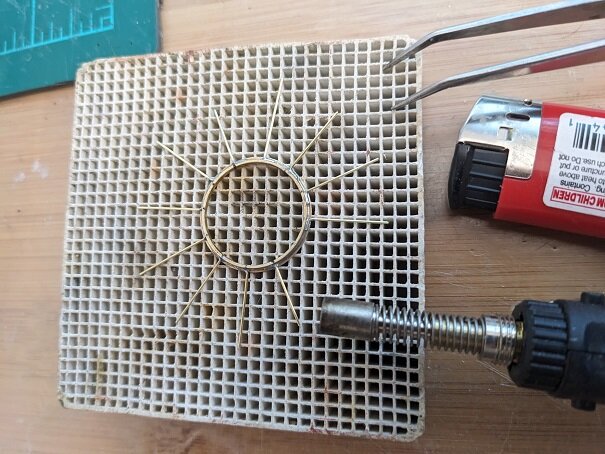

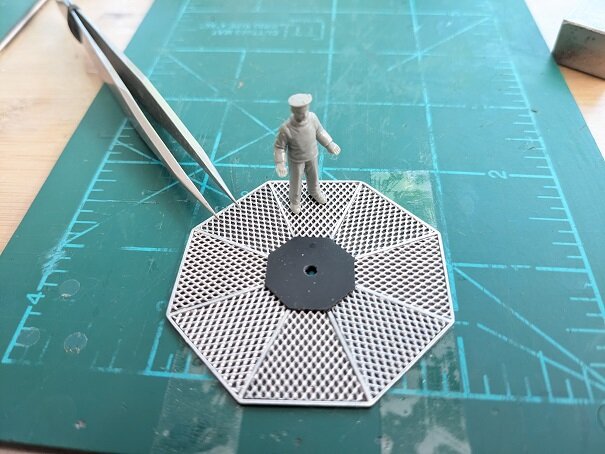

@Chronocidal Your model came out great! The canopy is not that bad either. DON'T buy a vacuum form machine. They're way too expensive and limit what you can do. Just get a wooden box and a couple of frames to fit snug over it. There's ton's of "How to's" out there. Then hook it up to your vacuum cleaner. Save the money for more models😄. @Urashiman That's one of the newer dazzling camouflage schemes!😁 @Chas Now that's going old school! Your mods look cool so far. @pengbuzz You are AWESOME with figures man! People would be looking at my sculpt and be asking, "Is that Mary Poppins?"🤣 He looks GREAT and accurate too! Photo 5: "The man's always keeping me under foot!" @derex3592 Your pilots look accurate and nicely painted! @Thom Wow! Talk about night and day! Two completely different builds! They're BOTH looking great, though. @electric indigo Bummer! Already looks like it needs a lot of putty work. I've been slacking with doing posts - sorry. One complaint: I don't have enough "likes" for each day to appreciate all the work you guys are doing! Under the Oto Melara on most ships is some kind of walkway to cover cables and installation hardware. It's also some kind of diamond tread plate or open grated material. So I went with the open grated material. Like I say, save cool looking bits for later on. This aluminum grated mesh went to some house decor we no longer have. But I KNEW it would be great for something later on... The white HO tread grating pattern SHOULD be smaller than 1/72nd scale, but as you can see here, it is WAAAAaaay out of scale with the figure. Thankfully the aluminum mesh is just right. A chrome paint marker made all the pieces go together. The gun magazine has a guard rail around it so people don't get into the carousel while it rotates. I've tried machining MANY shapes to make this, but they all failed! Too small to be strong enough. Thank God I got this ring machined correctly! To this I added "spokes" and soldered them in place. A TINY piece of solder was placed ON TOP of the joint and the flame's heat gently melts it into place. Then the spokes were bent upward. Note the marks on the pliers for bending and cutting the spokes. I used a pastry stone to do this work. Its FLAT and is also heat proof. "What can I use to hold the pieces down while I solder them together? A WWII 30mm training round!" It worked! Test fitting the guard rail... And a coat of silver on them to stand out against the black magazine. The other guard rail goes around the spinning part at the bottom. That's it for now. Thanks for checking in! - MT

-

@Thom The Asuka looks BEAUTIFUL! Clean paint and just the right weathering too. @pengbuzz Your fighter AND base look very menacing! COOL design of the fighter AND the base too! Great imagination! - MT