-

Posts

8220 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by seti88

-

-

Hmm, I'm betting that grey rectangular thing on the underside of the weapons pod is a beam gun.

i suspect that is the extension holding the back end turrent system (similar to the 30) that would rotate facing forward in battroid.

It does seem that they didnt extend it out in battroid for some reason,...

Functionality wise i would expect anything else from it...

-

Anyone notice the tidbit about 1/35 VF-1 valkyries?

Dang there was mention of it? i would be down with some of that if its priced nicely.

-

With today's anime industry, manly characters doesn't sell. Delta is going full speed with the moe designs, and hell..frontier has high school setting. It is what it is though.

eh yeah..the hardpoint wings will come with the Version 2 of the VF-31...

I will prob sit the first few releases out just to gather the reviews and such....famous last words tho...

-

Hmm, the toy is missing the wing hardpoints from the anime

oh no....hopefully its just because it isnt the final version yet?

-

Its getting real competitive but hopefully we can see price drops..I do realise its not a fair comparison between 1/100 and 1/60 but i do thk anything that fills "the need to own it" gap could take demand away from something more expensive...after all not everyone has a money tree...

-

ARCADIA you gotta put out that 1/60 destorid cheyenne pronto!! With delta trailer showing it, you better get a move on b4 bandai beats ya to it!!

-

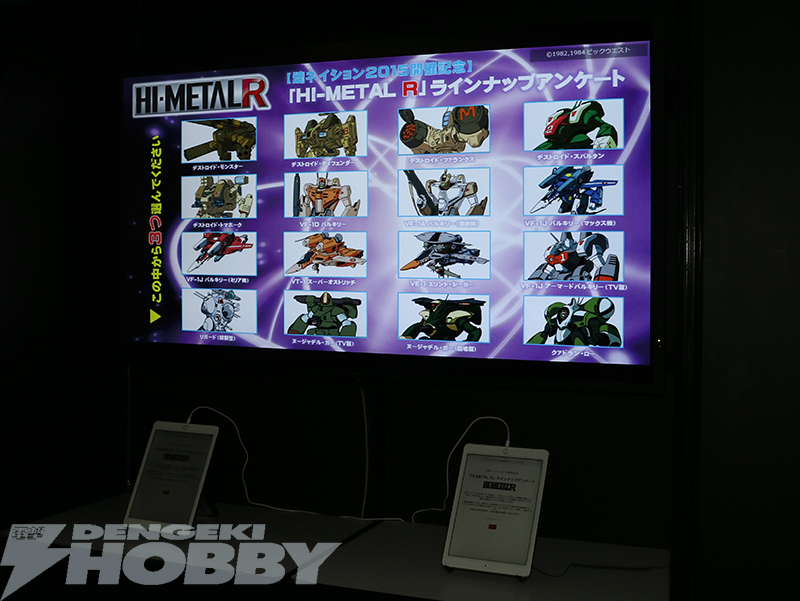

Hi-Metal R

in Toys

Ahh...gauging interest. Can someone vote for them all please?

where do we vote? or is this another JP only thingy...

-

Hi-Metal R

in Toys

HELL to the M-F'ING YEAH!!!

Please assume RAPE positions...

-

Hi-Metal R

in Toys

Here's a link with lots of pics , bandai is killing it

http://www.taghobby.com/1-0/1-1/不斷更新-2015年10月30日11月1日-tamashii-nation-2015-秋葉原會場展品-macro/

killing? slaughtering seems more like it!

REGULT missile carriers! breetai! destroids! macross 2 with SAP(still no pics tho)!!!

-

-

Hi-Metal R

in Toys

And the Macross 2 ones look AMAZING :-)

where where??!

-

Hi-Metal R

in Toys

ARRRRGGGHHHHHHHHH.............

-

Hi-Metal R

in Toys

MY Credit card is yelling........................ HELP!!!!

-

Hi-Metal R

in Toys

AM I READING THIS RIGHT??

Even as Macross moves forward, it still has an eye on the past -- here are some of the variable fighter and enemy toys teased in its 1/100-scale Hi-Metal R line:

The Super Dimension Fortress Macross: Regult (February 2016), VF-1S Strike Valkyrie (Hikaru in November, Focker in April 2016), Glaug (May 2016)

The Super Dimension Fortress Macross II: Lovers, Again: VF-2SS Valkyrie II (Nexx and Silvie with SAP)

Macross Zero: VF-0A Phoenix

The Super Dimension Fortress Macross: Flash Back 2012: VF-4 Lightning IIIwooooowwwwwww

ARCADIA is being destroyed!!!!

-

In its larger 1/60-scale DX Chōgōkin line, Bandai will offer:

Macross Plus: YF-19

please dont let this be a joke or a misread!

-

NICE!

certainly looks like curved back wings from the outline of the foot thruster intakes!

Plus the front shoulder outline is different from the back shoulder altho they are attached as one single unit!

-

-

Thanks for the post orindlt! It looks very nice close up

The battroid head unit looks mean..and valk has what looks to be a matt finish like the 30!

The shields on the forearms seem to be part of the

center delta wing piece!i thk i meant to say underside.Shoulder transformation seems to be a rotated and folded backcanard system!

awesome

plus do the wings in battroid mode seem to be curvy for some reason and it seems that the 30 brace parts are being used in battroid...

-

-

Macross Delta everyone!

HAHAHAHAHA

-

The only variation (besides color and insignia's) I see is the Lead one has pointed front wing tips and the others do not. Also, the 2 VF-31's with Insignia's also have double head lasers.

That does seem to fit in within established antagonist structure's...the case of the VF-27's again? One main commander, sub and CF's...

So, about 6 SV-262s, and 5 VF-31s...including all the future online exclusives of course.

Man, Bandai must used to be in the dairy products business, cause they sure are good at milking stuffs.

Am not too sure now abt the 5(or is it 6?) variation count. It looks almost to be 3 only based on the poster and from what wmkjr pointed out..

-

Check again the image Swoosh posted. On the 31's left shoulder you can see there's a corresponding back piece on the top. It's kinda deceiving at first esp on the right shoulder since it has an 'exposed' circle looking shoulder. That's why it has that illusion that the canards are somehow covering it like an armor.

But then again, it's still early to really say how it transform.

But then again, it's still early to really say how it transform.

i thk the back piece on the top left shoulder would be the extension of the back/folded tailfins jutting out from the angle of the pic.

Plus from the gerwalk it certainly looks as if the canards are pointed directly downwards to form a shield for the shoulder.

more pics from more angles would help...who is at the expo that can take some close up's?

-

-

Paint scratching galore but a definite buy for me!

which color are you going for or all of it?

BANDAI DX YF-19!!

in Toys

Posted · Edited by seti88

I dont get it tho, as i would thk that arcadia would have some exclusive hold on the M+ license for 1/60 as they released the YF-19 fast pack version not too long ago. This is from reading abt all the licensing issues from past forum postings..

Unless of course its somehow recinded from arcadia's part?

and for that same reason, M7 licensing too..