-

Posts

570 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by tundrayeti

-

Thanks guys the door will be toned down a bit, The weathering is just the underlay, Now I have to do the salt technique and then a little touch up. Who doesn't love some blinking lights?

-

Latest update. added a microcontroller to the control panel so that it will simulate some activity. I also have some pics of the generator, and the weathered doors. Last pic is of the graphic overlays that will go on top of the LED's to make the screens on the control panel. Let me know what you guys think and enjoy the video.

-

Send me a PM. I am finishing up a third run of those and looks like I'll have a few extras.

-

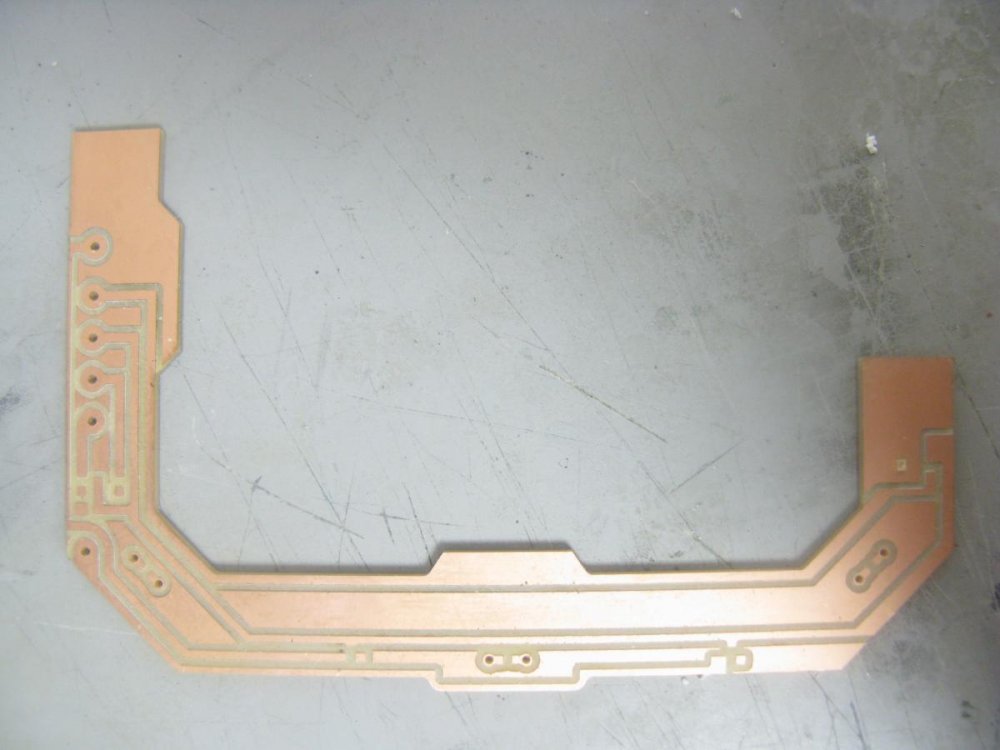

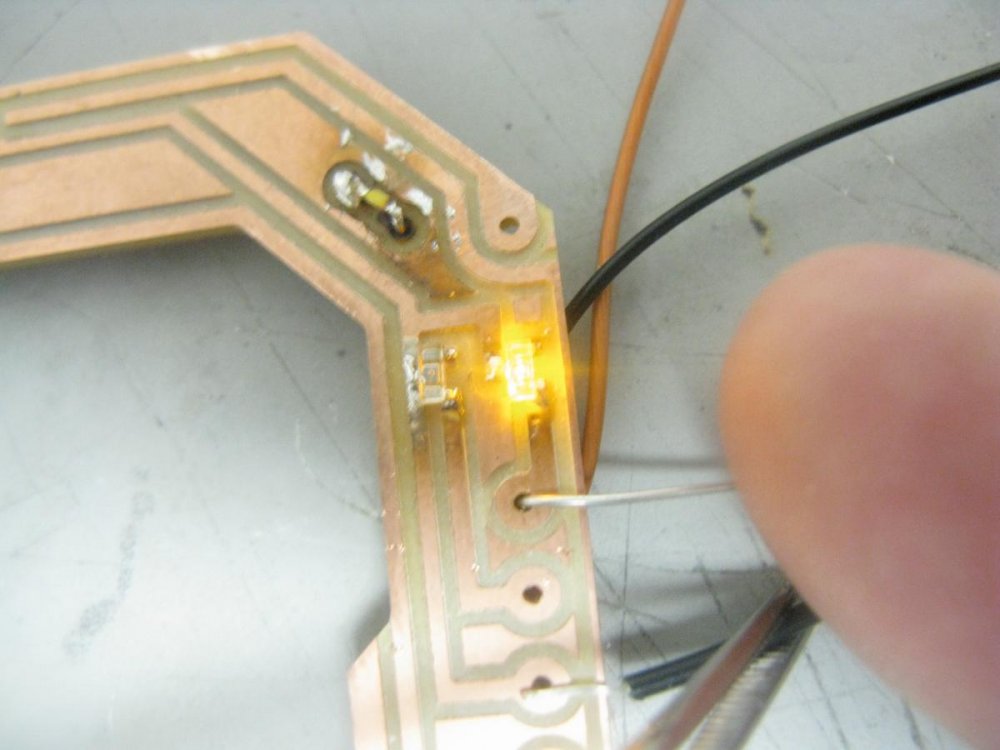

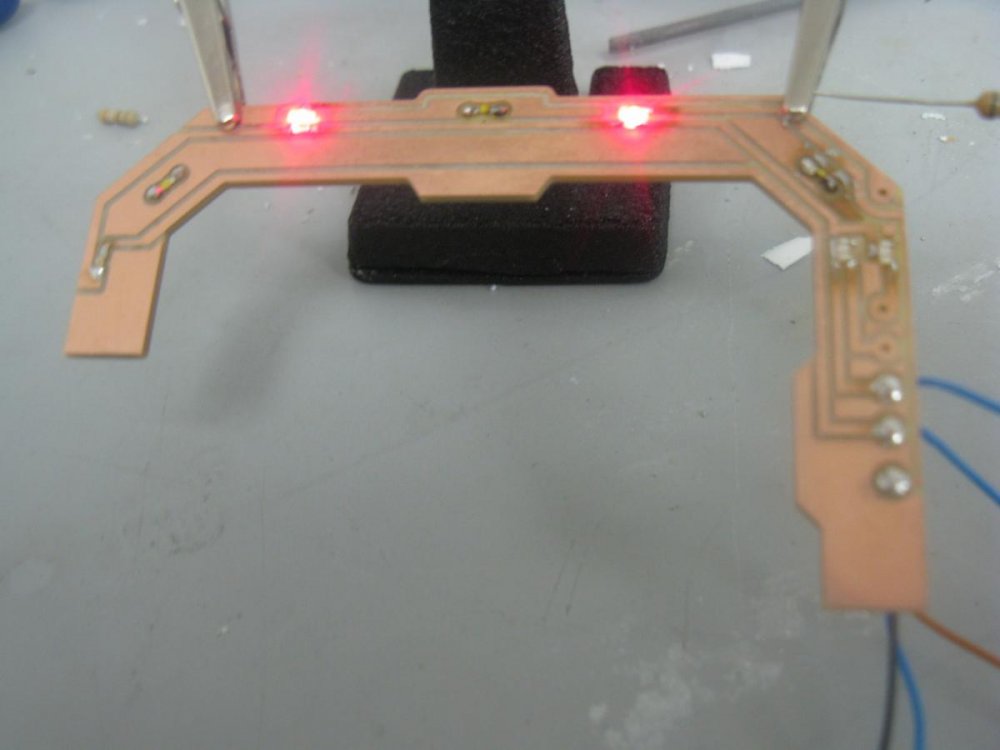

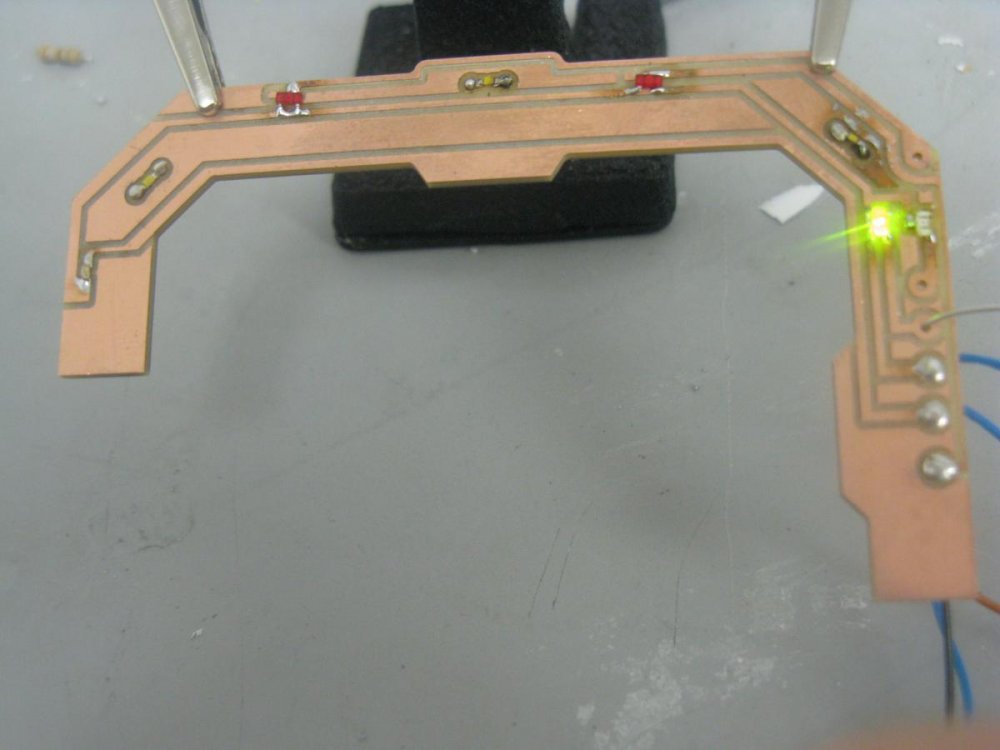

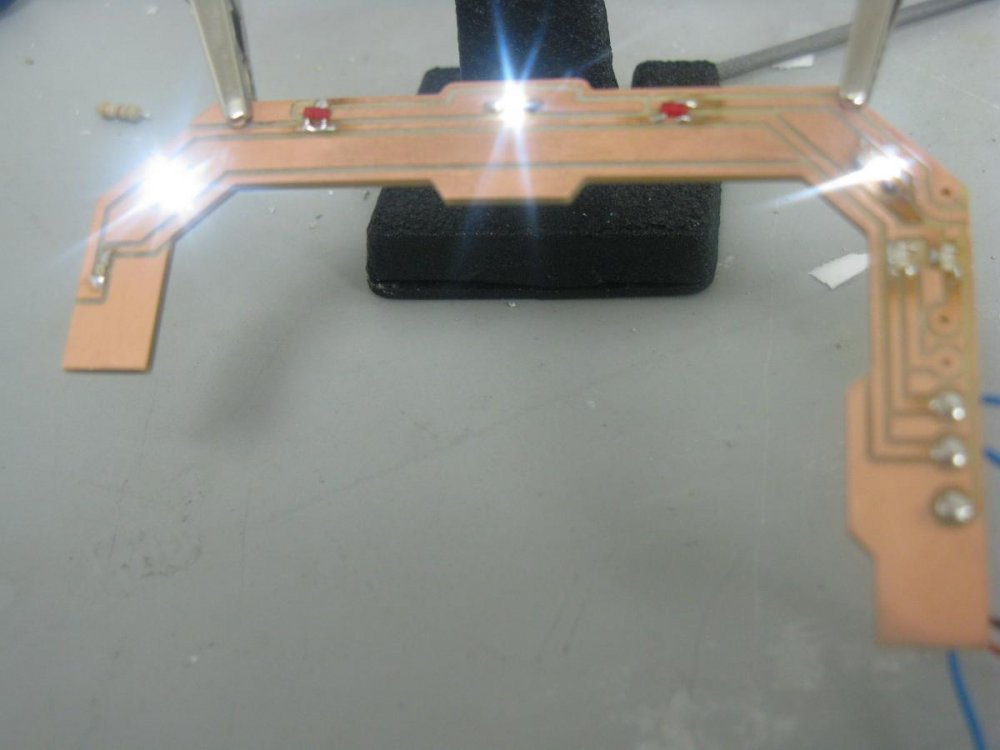

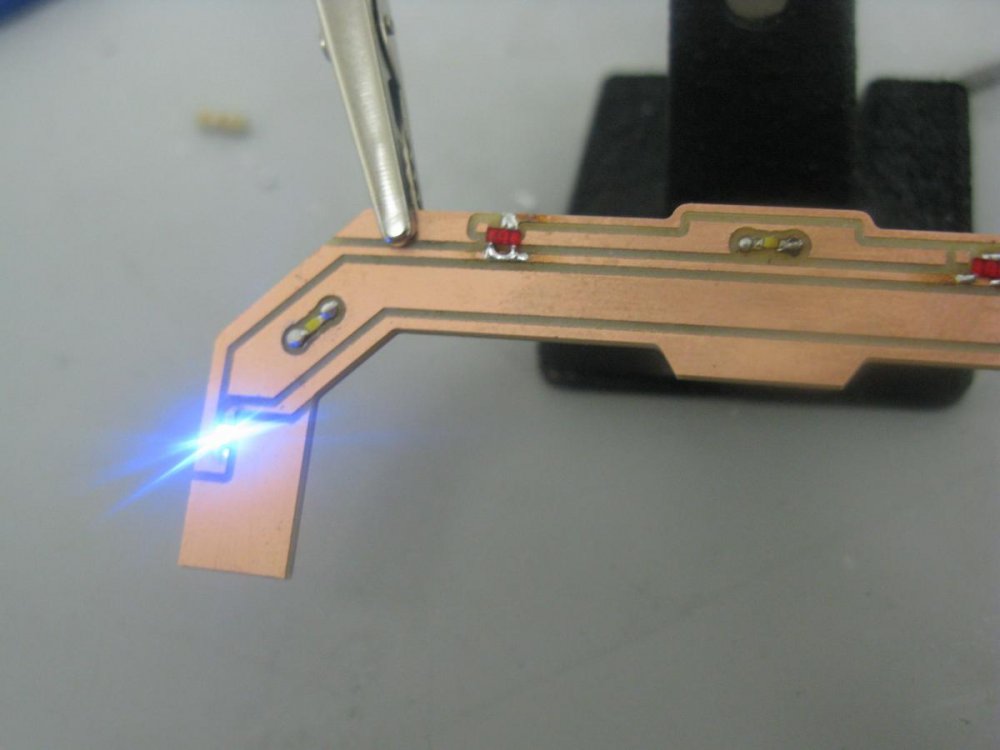

I am always trying to come up with ways to take things up to the next level. Well I have been mulling over this idea of actually making the control panels light up and do some cool effects. Well Here is what I have come up with. I have never done this before, but Using my CNC machine, I fabricated a circuit board using double copper coated plain circuit board you can buy at any radio shack. I made the connections using a very tiny .032 inch endmill. The results came out looking pretty good. Here is what it looked like: Then I soldered SMD LED's to the board and tested them. I will have the tiny flasher chip installed later this week, but as you can see they all work as they should. some will stay lit and some will pulse and flash intermittently. I used the parts from the old control panel to test and see if this will work and it looks good. Once i get a new part made, i will cover the LED's with some tiny graphics that will make this come to life.

-

Brett, that is correct. Everything else is ready to go. For those of you waiting on this, and some of the ground vehicles, I will send you them and ship the mom's kitchen when it becomes avaliable. everything else is ready to go. Got them boxed up and ready to go. I can even ship the kit with the cast canopy and send the vacformed one later. PM me and let me know what you guys would like to do. I'm trying to wrap all my other projects so I can move on to other ideas. I know the hangars have a waiting list, so hang in there guys. I have something new on the 1/60 hangar that will knock your socks off!

-

Looking good EXO! can't wait to see how this comes out.

- 138 replies

-

- 1/3000

- Prometheus

-

(and 3 more)

Tagged with:

-

Unfortunately my ho's name was the mom's kitchen... okay that didn't sound right. Anyway MT you are so right, at least you can say your mistress is a model..

-

hell just throw in an alien queen for kicks!

-

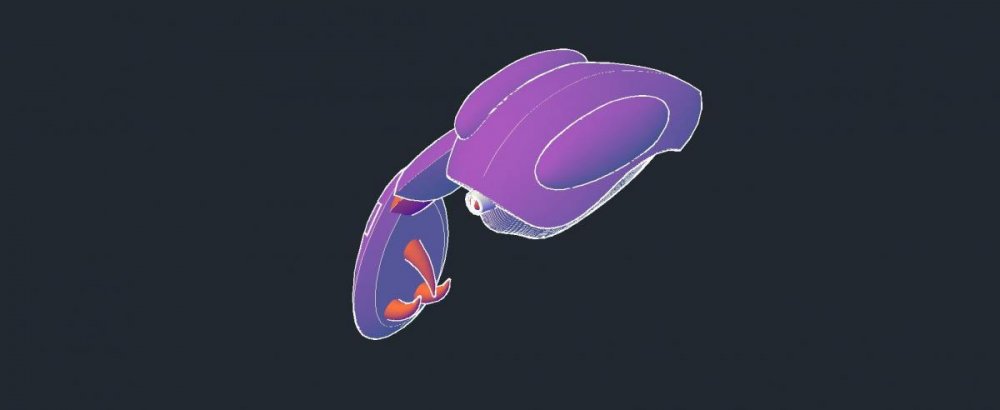

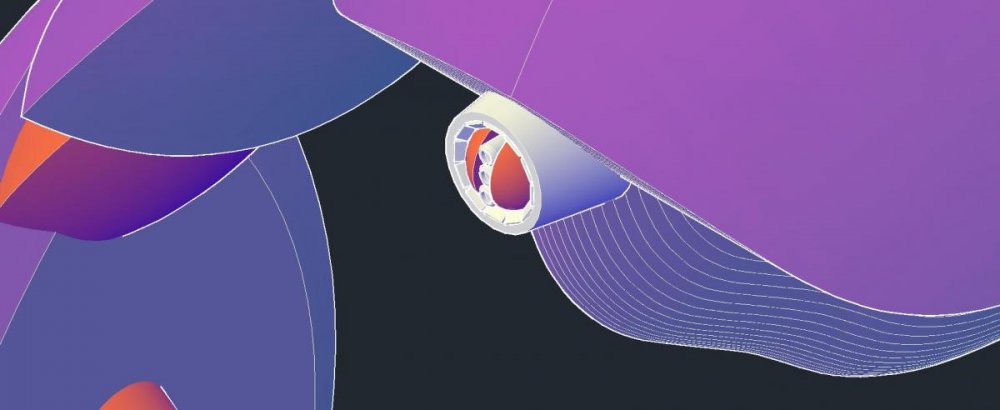

Okay, here is a long overdue update. I have been working on some of the smaller details on this hangar. Lots of small greeblies and piping work. I couldn't get pics of everything, but I have started the control console for the work stations, and also detail work on the doorway. Enjoy!

-

Looking good Alex.

-

Upgrade parts for Beagle 1/10 Mospeada

tundrayeti replied to EXO's topic in Anime or Science Fiction

No problem, Hit me up when your ready and I'll shoot you the guy's email address -

tell me about it this humidity has been MURDER!!! I went on a business trip to san antonio last week and it was nice and dry. Come home, hoping to get the grass cut and all it did was pour buckets. UGH! Well the rest of the kit parts are good to go. Been getting a lot of requests for other scales. Those of you really interested in a 1/60 or 1/48 pm me so I can get an idea of how many folks would be interested in this. I will be doing this in 1/100 scale for myself, so if anyone in interested in that scale as well. I'm not going to get into this until i get the rest of the projects I have going on finished, but i will get to these eventually.

-

But Legos are meant to be destroyed, and then put back together, and destroyed, and ........ Just put together the Lego X-wing my daughter got for her birthday

-

Well the sets would basically be the same as the other scales. They will basically look the same. I'll see what I can do about getting some pics

-

I think it's cool I'm not the only dad with a little girl who loves Star Wars! Those snap kits are great for kids.

-

Yes they are. I am currently on the third run for both sets. Got a little overwhelmed there because my company kept sending me out of town. For those of you who have been waiting I appreciate your patience,

-

Okay latest update on the vac-formed canopy. TERR-OR has sent me these pics. The mold is almost done, and they should be getting done here soon. So thanks for all your patience everyone, it's about to pay off. I was out of town all last week so I'm trying to catch up on everyone's PM's

-

Upgrade parts for Beagle 1/10 Mospeada

tundrayeti replied to EXO's topic in Anime or Science Fiction

I already have a rapport with one of their printing guys. Let me know if you want any assistance -

great minds think alike.... although I was going to do them in a different scale... and this was just screwing around while I was traveling

-

Upgrade parts for Beagle 1/10 Mospeada

tundrayeti replied to EXO's topic in Anime or Science Fiction

-

Upgrade parts for Beagle 1/10 Mospeada

tundrayeti replied to EXO's topic in Anime or Science Fiction

They still are taking orders. Their work is top notch. Just do a google search for Owenage 3d printing and see the stuff they have done for others. As for the 3d scanner, I'm not sure what setup he was doing, I know he did a couple of test scans. But as always other things get in the way. -

Upgrade parts for Beagle 1/10 Mospeada

tundrayeti replied to EXO's topic in Anime or Science Fiction

The name of the company is Ownage in China. They do awesome 3d printing and they do a LOT of anime stuff so they have a passion for stuff like this. And as far as the 3d scanner goes, My friend is still working the bugs out of his.. It's definitely a touchy technology. -

Well the weather just recently cooled off considerably here. So I will give the clear another shot and see what happens. TERR-OR is working on the Vacuformed canopies and I will check in with him this weekend. everything else is ready to go folks, so lets see how these canopies turn out. I'm going to try to post some progress pics of my build of this kit, hopefully this weekend. Thanks for your patience everyone,

-

Upgrade parts for Beagle 1/10 Mospeada

tundrayeti replied to EXO's topic in Anime or Science Fiction

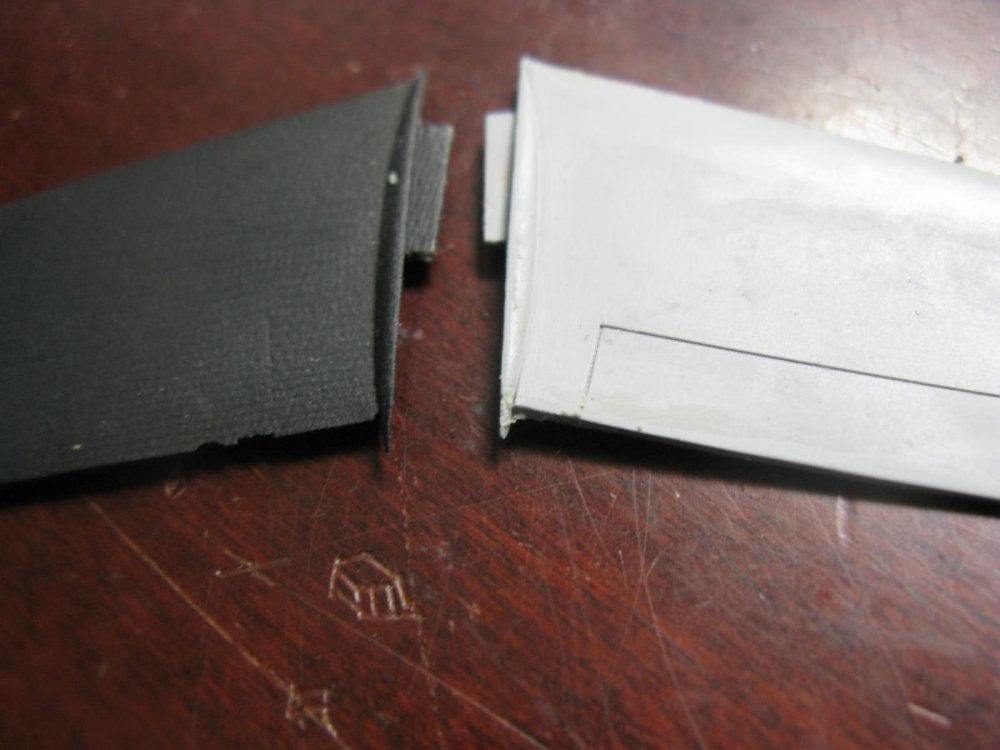

I have been disappointed with Shapeways all around. They used to put out some quality work for an awesome price. One of the biggest irritations for me has been, (like you Alex) that they have changed their standards as far as wall thickness goes. But if you look in their materials section they haven't publicly mentioned it. Back when I did the 1/72 scale Ground support vehicles, I uploaded an stl file for my steering wheels and it turned out to be like 5 cents per steering wheel. Not too bad. Then they slapped on this $5 setup fee, so the price went from 5 cents to 5 dollars and 5 cents. ridiculous, but my way around this was to copy the steering wheel MANY times. so if I printed out 100 steering wheels they were still 10 cents each. Still acceptable. That same file that I have printed MANY times is now rejected. Now even this is inconsistent. Here is another example. I have included the pics of the VC-33 rear stabilizers as I mentioned yesterday. Now this file was rejected by shapeways twice with no explanation, even though I asked for one. So i submitted it a third time, Same file, no changes and the third time they printed it out and sent it to me. Now this was done in ultra fine detail, Which is supposed to be their best quality. It seems that the tech just printed it out and threw it in a bag and shipped it because this thing is horrible. Now for the comparison, The part in black is the Shapeways part, you can see it's got obvious steps and breaks in it. I did give it a coat of sandable primer as I was going to try to salvage the part. The part on the right in grey is another company i tried and the grey part is exactly how i recieved it. (well there is a bit of residue from the casting process). This company gave me a finished product that I needed no prep work on. and the price was only $22 dollars more than Shapeways. Now this may vary with other printers, but i can tell you I'm willing to pay a little more if I can get a part that looks like this. I can just put it in rubber and be done with it, no prep time. Okay I'm done with my rant, just wanted to let everyone know that Shapeways isn't the only solution, and there are places that give you good quality prints at decent prices. Of course this wont facilitate folks who own stores on Shapeways. Alex, I think it's more cost effective to print your parts out as masters and make molds. There are plenty of folks who could help you with this on these forumns. Thanks for looking.