-

Posts

4691 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

I'm just now seeing this, but it came out AWESOME! Great design and building! - MT

-

This thing is a museum piece now! Looking great! Keep it in a covered case. - MT

-

The TIE looks great Derex! The laser effects are a nice touch. Pengbuzz, I'm glad to see your model got spared the death of hitting a wall! It came out great and was a good save! NZEOD, I need sunglasses to look at all that bling on your model! SHINEY! Got a LONG WAY to go, but it's starting to take shape now. Just fit the parts together to get an idea of things so far. Asked my wife for some ideas and feedback and all I got was "whatever floats your boat!" Thanks babe! This will be a modern fast missile patrol ship when done. - MT

-

Milliput is GREAT stuff! Very strong structurally too! - MT

-

That looks great William! You can't tell it's 1/144 from the photos. Is it just me, or does Han look REALLY grey haired now! I'm with ya William! I've had to sort out several ways of magnification even adding it to a couple of machines. Between last year when we moved house and a couple of months ago when I started back seriously into building, I lost part of my vision. Maybe it's in one of the storage boxes from the move... The Valk is coming along great Pengbuzz!- MT

-

Many people say the A-10 is an ugly plane. That is until it's providing cover overhead! This looks great! Are you going to give it an acetone bath to smooth it over? - MT

- 14 replies

-

1/72 Imai VF-1S Kitbash PART II: The VF-1S STRIKEs back!!!

MechTech replied to pengbuzz's topic in The Workshop!

Lookin great! I'm glad to see your back on it. Sketchly's right. I've even used "blochin" as a finish. Keep up the great work! - MT -

The face plate upgrade looks great Electric Indigo. What is it with those era Gundams? They always seemed to get the proportion wrong. How about "Chocolate Thunder!" It works on multiple levels - MT

-

Hasegawa 1/72 VF-25F/S Super Messiah Macross Frontier

MechTech replied to Mintox's topic in The Workshop!

Looking great Mintox! - MT -

Pengbuzz, that sucks dude! I think those guys forgot where they came from. NOBODY takes a model for the first time or even first few times and makes it look AWESOME without some bumps here and there. On the other hand, it's great that we do have some nice people on the forums! I've been on these forums for years and I can't tell you how many people started out asking for help to becoming near professionals giving help. You also get the TENACITY AWARD for not giving up when the model went far from what you wanted it to. On a side note, if you're on a tight budget, need styrene but don't have a hobby shop or hobby shop budget, go to the big stores and buy yard signs. Walmart has a $1.00 "Keep Out" styrene sign made of either .020" or .040". Just turn the lettered printed side to the inside. Or buy two and hang one in your work area NYANKODEVICE: Your scheme and finish look great! I think your design is better than some of the Palladium books creations. - MT

-

That thing is HUGE! The gunpod looks like it could fire BB's! The shnoz does look too long! Hopefully it's the camera. It does look off. I had an old camera that would warp anything like that. My 1/100 Monster barrels looked like they were sagging in photos - MT

- 1065 replies

-

- max factory

- dyrl

-

(and 1 more)

Tagged with:

-

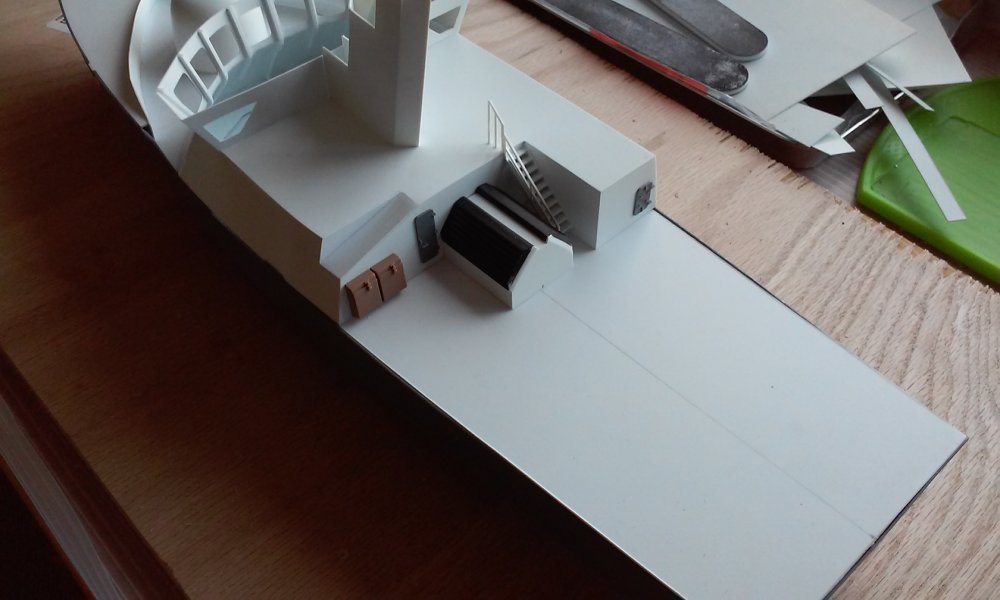

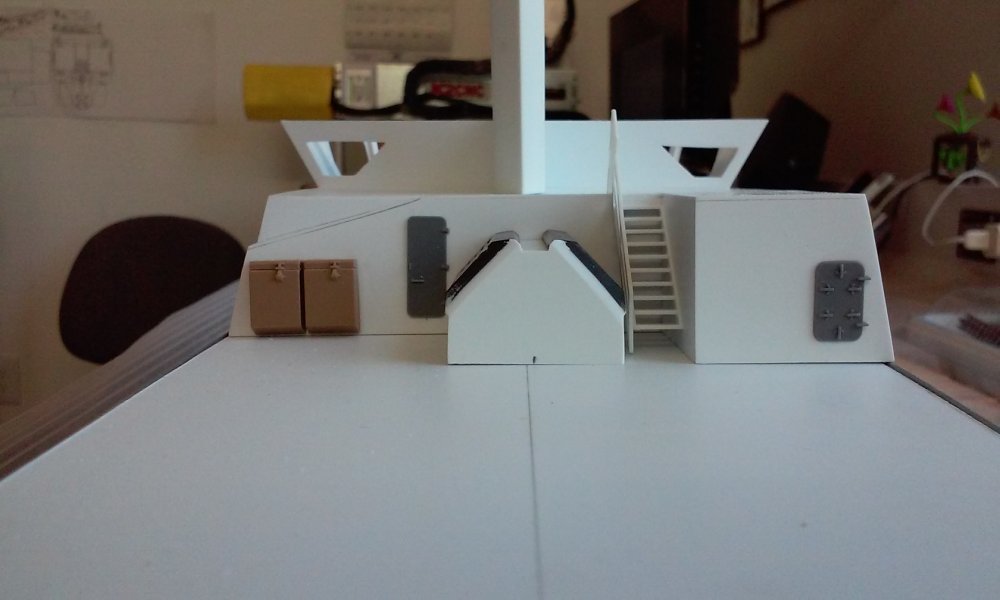

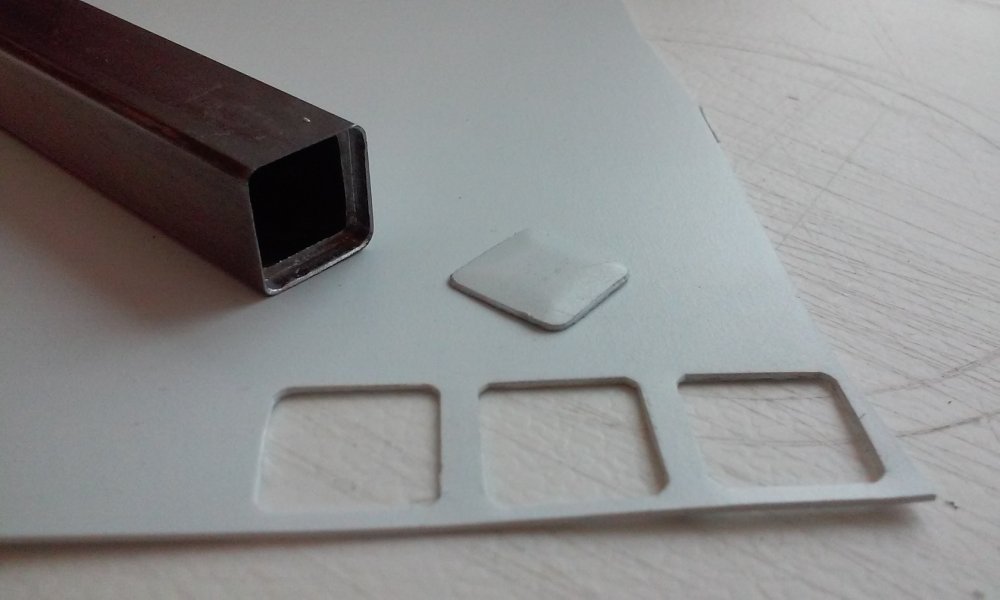

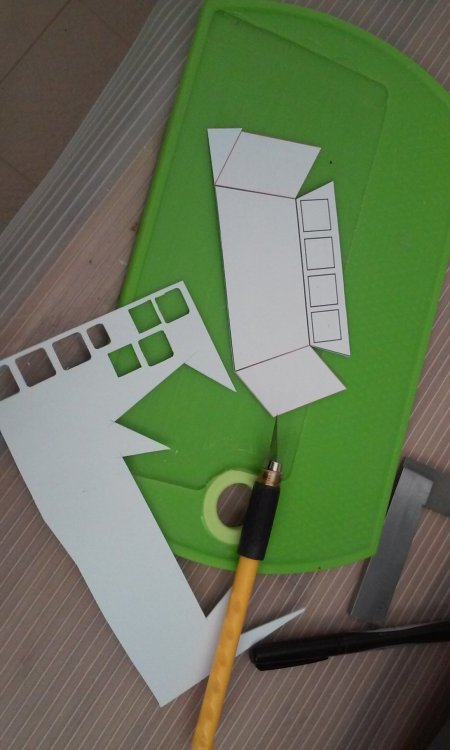

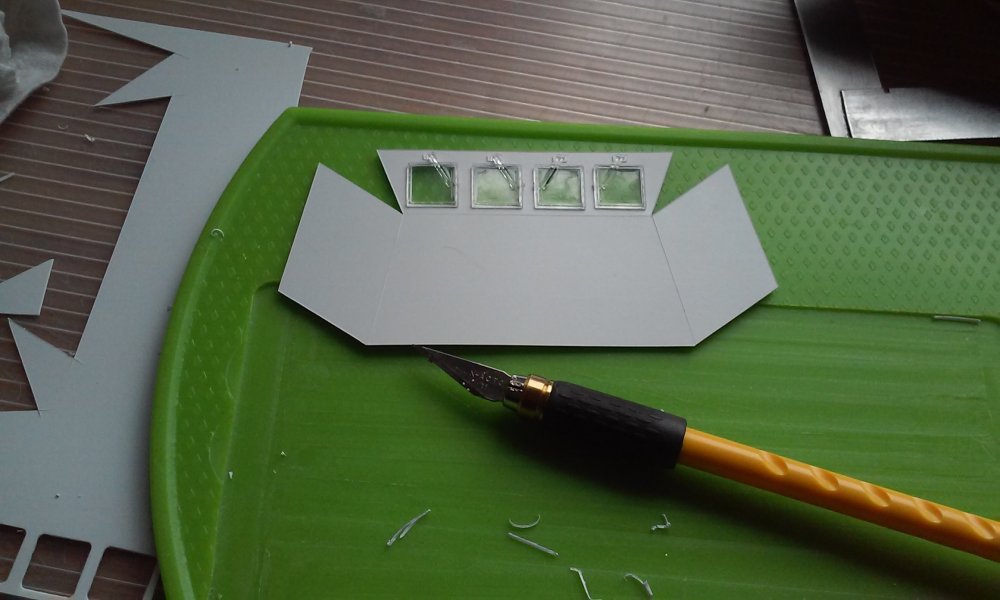

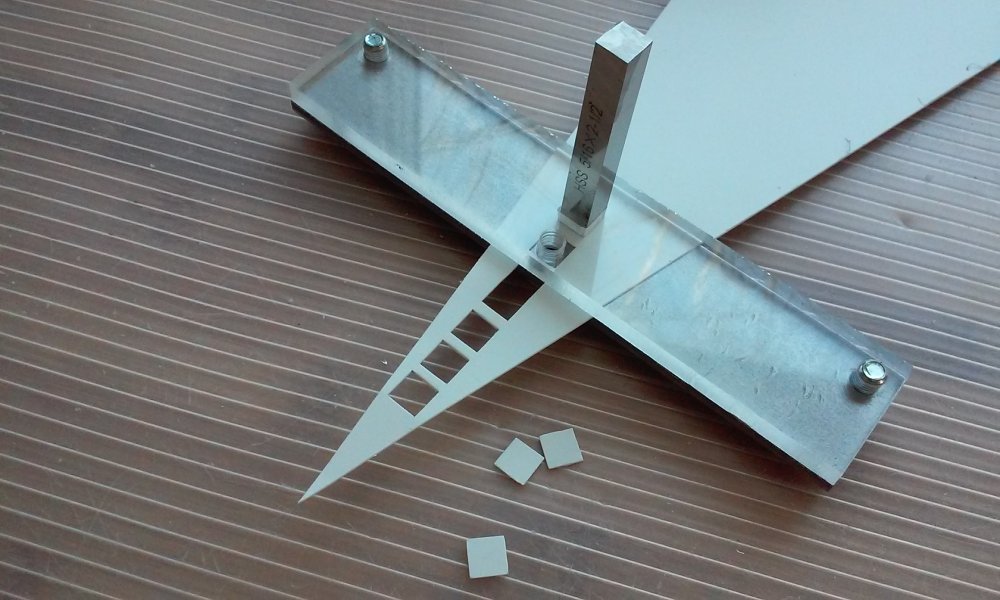

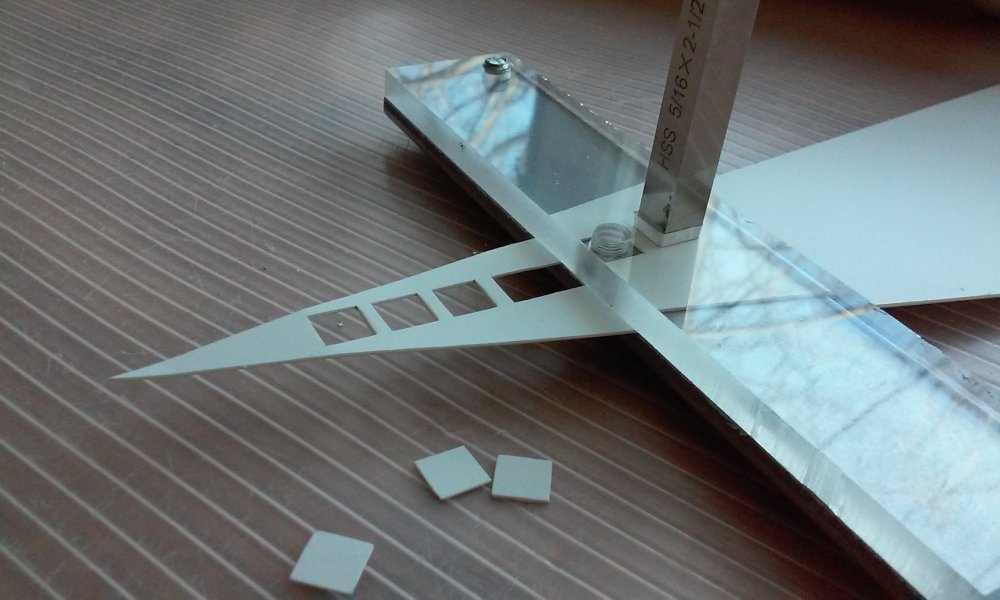

That looks great Thom! Nice finish! Your paint and scheme look great Nyankodevice! The lines are a nice touch! So far I seem to be doing more metal work than styrene work! You know how cutting windows or square holes is a pain and they never seem to quite come out right or need a ton of clean-up? What if you had to make a bunch of them? I machined two steel punches. I'm trying out two bridge designs. One with the big punch and big windows, the other a smaller punch and smaller windows. The test bridge is shown in the photos. The smaller test bridge still needs to be drawn out and designed. - MT

-

Wow, I blinked and lots of cool stuff is made AND Derex gets engaged! Congrats Derex! If they EVER do a live Macross Movie, they'll have to include the River Dance scene! - MT

-

Sorry, the "Macross" roundel has been around for decades! But that's what I thought the first time I saw it! Makes you wonder, who came first, the Macross or the egg (paint can) - MT

-

Bandai Macross Δ Mecha Collection Small Scale Plastic Model Kits

MechTech replied to IXTL's topic in Model kits

That's looking really good so far! - MT -

The stuff we want goes to vaporware and the stuff like this makes it through. I'm confused!? As Arbit said, "this won't end well." - MT

-

Thanks for posting the pics! I hate the 3D printed prototypes, there is so much that can change before the production model comes out. But it looks better than the last bland shapes we saw. - MT

- 1065 replies

-

- max factory

- dyrl

-

(and 1 more)

Tagged with:

-

Looking great guys! I made a steel punch for windows and I'm still working the bridge design before cutting styrene. Derex, why don't you try thin decal strips that color or paint some portions of decal sheets for the SDF-1? Then carefully with a SHARP razor cut the strips the width you need. That's how I keep my sanity with small models and THIN lines. The decal paper will still lay down flat with paint on it. Enamels seem to work best. - MT

-

It's "compoundo" guys! I just usually use some isopropyl on a swab or rag to clean up excess. Too much cleans out the panel lines. Do it Arbit. You got the motion, get the lights too.- MT

-

That last video looks AWESOME Arbit! Well done! The droid and speeder came out great Derex - roger roger! - MT

-

Arbit, get some felt for your stand. It won't stick to the paint and will last for decades. It looks great by the way! - MT

-

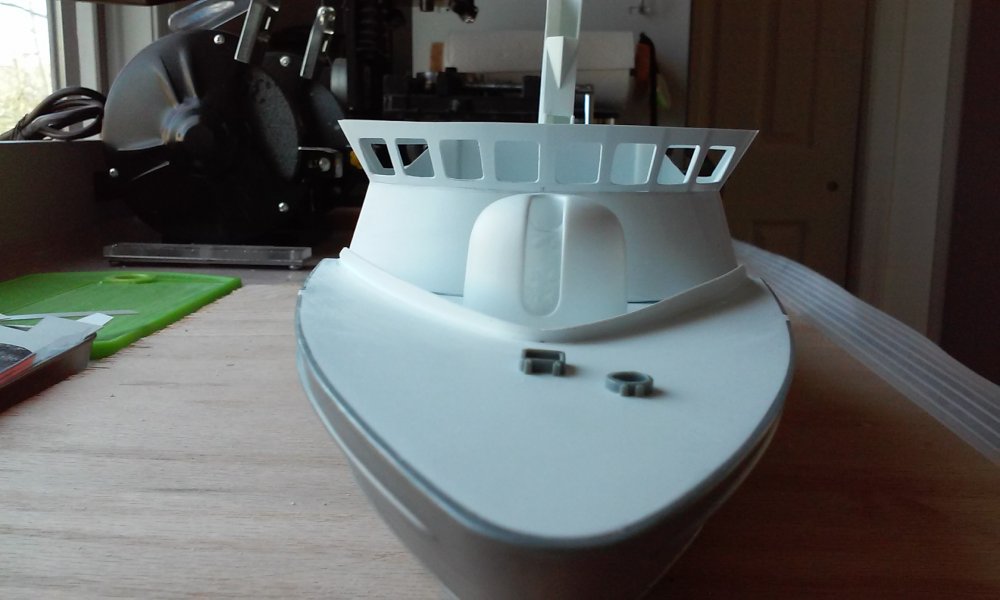

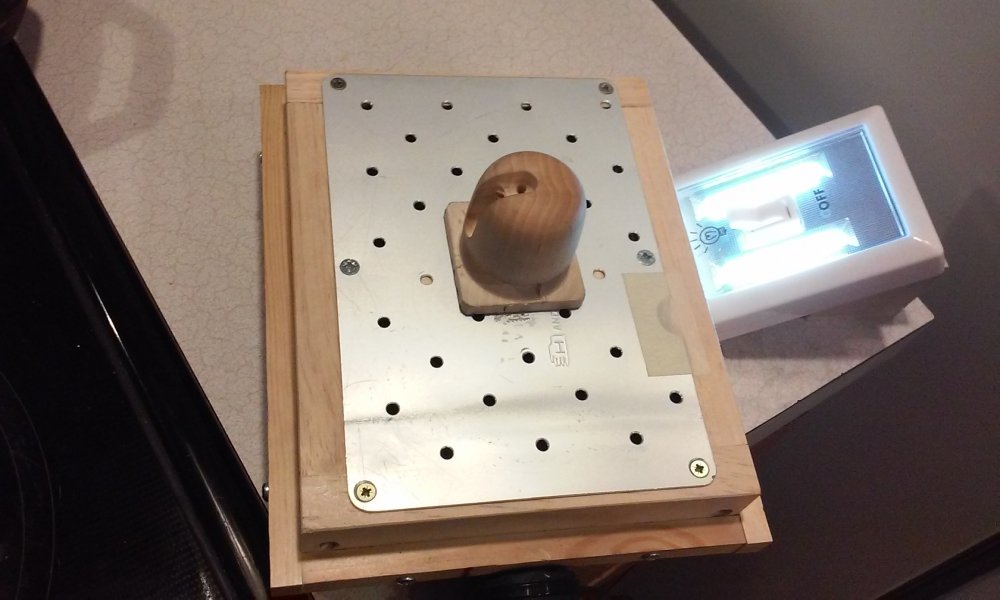

Chas, ha ha, the first one has a tire for a butt! Talk about leaving tread marks! They all look cool though! I posted more in depth detail and photos in the beginning modeller's thread, but here's my first attempt at vacu-forming in a couple of years. Long story short, I'm building an Oto Melara 76mm gun turret for my 1/72nd scale ship. I built one 15 years ago out of those vending machine toy capsules, but as you can see, it is WAY too big after looking at the official specs (I only could get photos back then). The buck (mold) was made on my lathe and the gun port was machined out with additional holes to pull the hot plastic into it. My first attempts wasted a couple feet of plastic as I didn't realize I had TOO MUCH plastic around the buck making it web up instead of conforming. After doing some research, I realized that an adapter was needed to reduce the plastic that could be pulled over the buck. So that's the next photo. After that, I had 100% success and made four. Slap it back on the lathe for a clean cut around the circumference and I'm back on track. Back to my school work - MT

-

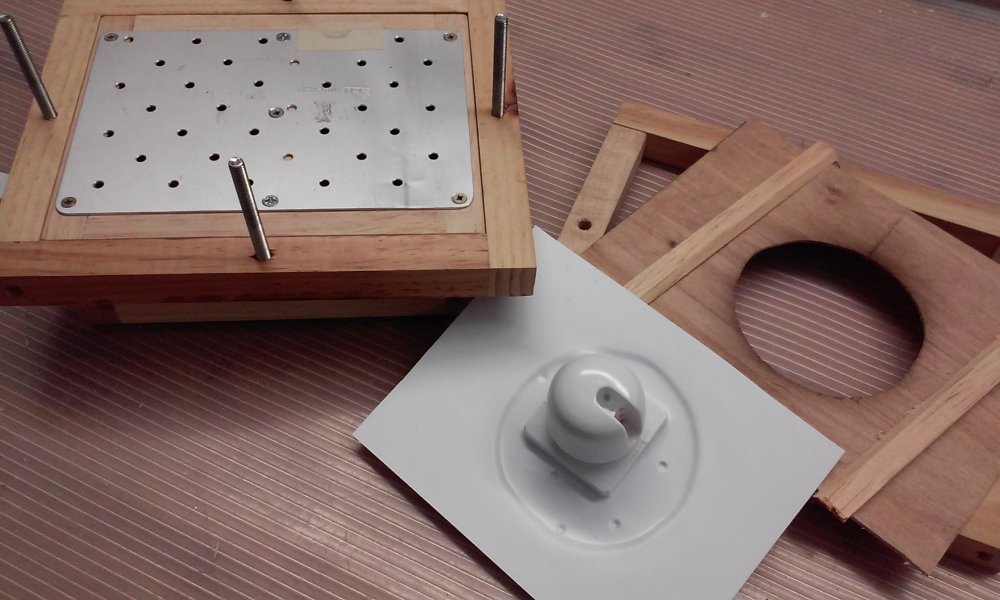

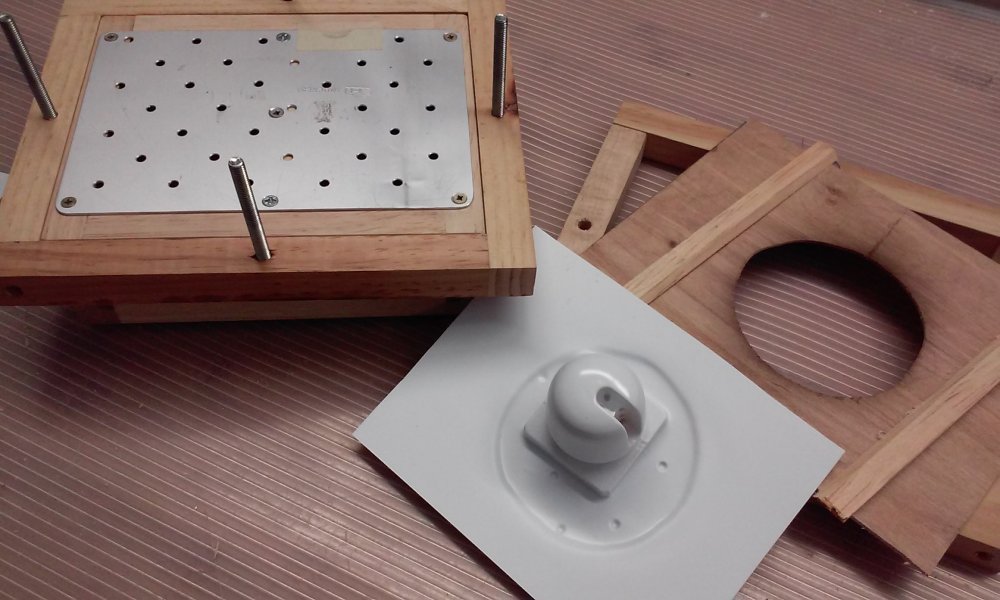

For those of you looking to do some vacu-forming, its been a couple of years since I did my last project using it. I forgot some things and wasted a lot of plastic thinking I was having temperature issues with the plastic. Long story short, think of a blanket. When you droop a BIG blanket over something, you get webbing in between where the blanket hugs whatever you are drooping it over. I did some research and was like "DUH" - forgot about that!" So I took the vacu-forming box I made and added a plate with a hole in it to reduce the plastic available to pull over the mold or "buck". Plus less plastic means I wasted less. So a quick walk through for anyone wanting to do vacu-forming. First I made the "buck" on my lathe and machined the gun port into it. In order for the plastic to get into nooks and cranny's, you need air holes for the vacuum to reach in there and pull the plastic in. This will be a 1/72nd Oto Melara 76mm ship's turret. Next is a photo of the buck and original turret I made like 15 years ago. Long story short, it is WAY too big and kinda heavy to go on an R/C boat. The photo with a pulled (molded) piece on the lathe shows the failure of having TOO much plastic around the buck causing webbing and ruining the part. To add insult to injury, I still had to cut it off too! Next photos are the vacuum box with frame to hold the plastic. Since the adapter makes a smaller hole that is hard to line up with the buck, the light helps you see and align them up. The next photos show successful pulls and how they were cut off on the lathe. The last photo shows the buck and molding. Note the holes in the buck to suck the plastic into the gun port. (sorry, photos wouldn't load in order no matter what I tried) Hopefully this helps someone and you don't waste a couple feet of plastic like I did! - MT

-

Bandai Macross Δ Mecha Collection Small Scale Plastic Model Kits

MechTech replied to IXTL's topic in Model kits

That looks REALLY good! - MT -

Nyankodevice, what about a dark red or maroon color with black accents? Maybe dark red and darker red accents? Just and idea. - MT