-

Posts

4691 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

@peter A wash makes a world of difference! @pengbuzz That's one way to get models off your "to do list" fast! Sorry man! - MT

-

Wow guys, I don't check in for a few days and you go bazerck! Got some work done on the cannon, but need to take photos. @peter I love your molten metal pot marks! That's a great idea! I like how your ATAT came out! Nice color blending. Your battle damage on the Birds of Prey look cool too. The screen was a great idea! Admit it, you found another way to get the hardware store into a model, even a small one! It's funny you're using XF-71 for that color. I think that is the same color my gun mechanism will be when done - or close to it. @pengbuzz That sucks about the canopies! I'd definitely vacuum form new ones. A Maverick Tomcat would be cool. It's great to see some classic plastic being built! Your SDF-1 looks great! Great save on the stand too! That model is a CLASSIC for sure! @Bolt Nice mods! I think that will look good when done. - MT

-

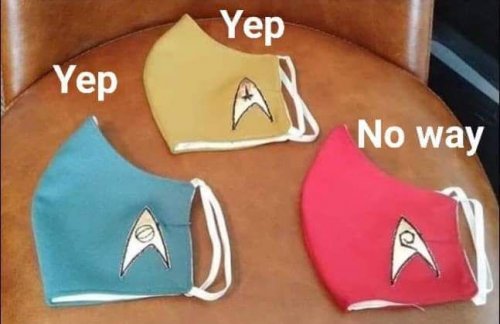

@pengbuzz "KAAaaaaahhhnnnn!" That's a GREAT vignette Pengbuzz! I love how you put the two together and even scratch built a badge! Is Kirk's chair made with "Corinthian leather?" That's cool (And I'm not even a Trekkie - which evidently isn't a word). - MT

-

The 'Hey look at this really cool model build I saw' post

MechTech replied to Shawn's topic in Model kits

Yeah, canopies suck! Yes, I agree, everything does look right! - MT -

@peter Great work on your projects so far! I'm glad someone's getting some painting done. It's going to be a while for me while I'm still machining and gluing. - MT

-

The 'Hey look at this really cool model build I saw' post

MechTech replied to Shawn's topic in Model kits

@Gabe Q They probably buffed the windshield and used a Mop n Glow coating. There's some stuff for motorcycle lights that gives a pearlescent sheen too. I gotta get some of that! That is a GREAT build! He mottled the heck out of the paint, but it works! It looks VERY sun bleached - like being out in space without cloud cover to shield it! Hey, it's STILL for sale!- MT -

@ChristopherB Congrats on getting that great collection together! Are you looking for this listing of kits (on the legacy page): http://www.macrossworld.com/macross/models/imai/imai_main.htm Hey everyone, it looks like this is for collections, not builds. If you have a build in progress, I would post it here: - MT

-

You get EXTRA credit Kelsain for doing contract work too! - MT

-

@peter That sucks about the decals, but your work looks great despite the issues. Use MicroSol Super Film to cover your decals. You can just hand brush it on. It will reinforce them and is also good for coating your own decals too. @derex3592 Your crew is looking great Derex! I'm going out on a limb, but my bet is that the "red shirts" are the first to get "written off" the show! - MT

-

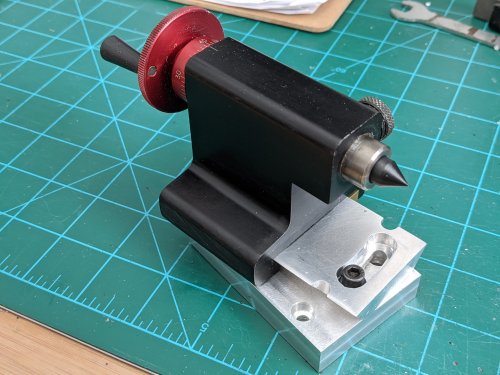

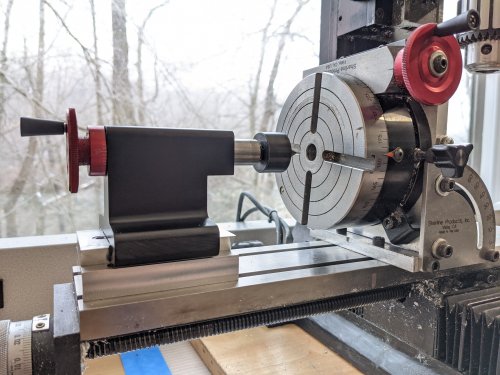

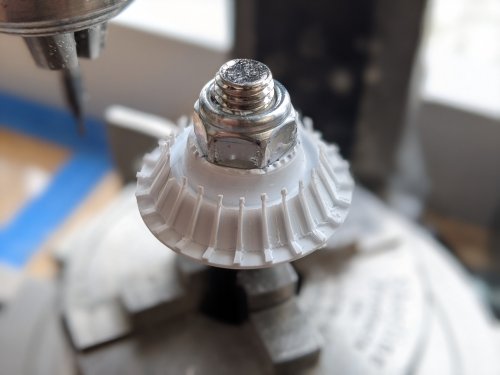

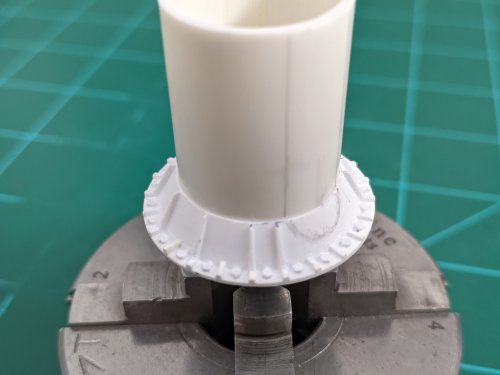

@peter Your weathering came out great! Sometimes a smear is more realistic than an airbrush! @electric indigo Your finish is realistic as always! It's just missing a smokey exhaust plume and you could hardly tell the difference! @derex3592 That is crazy they made the kit like that! Well, congrats on getting them all on! Now you know why I made mine punched into the deck. All that PE work would be crazy! I don't know what it looks like there, but everything here has a coating of ice on it. Half of the bit of snow we got melted. Something different this week. Shiny! My rotary table is used to rotate parts around or rotate them in increments (like cutting teeth into a gear). It's how I made the THIRD version of the attached photo for my gun turret. I had nothing to support long pieces like model gun barrels or shafts for cutting splines into. So I machined a couple scraps of aluminum (courtesy of my local recycle center) to make an adapter for my lathe's tool stock holder. Some work isn't always straight cuts, so I added the ability to make it swing out a little. They sell a similar adapter (without the adjustments) for about $100! Forget that if you can make one (that's what you get a mill for in the first place - to make stuff). Long story, I messed up on both prior gun mechanisms for below deck of the model. So the third time I think I got it right - I hope! Most of the pieces of the crown on the part will actually be cut off, so the broken piece is OK. Take care everyone! - MT

-

The 'Hey look at this really cool model build I saw' post

MechTech replied to Shawn's topic in Model kits

Did somebody confuse Mak with Macross? - MT -

@derex3592 The Ft. Worth is looking good! I can't believe they made you photo etch the padeyes on the flight deck - that's just wrong! The Runabout is looking good too! A full crew will add realism to the interior. @peter I think you MORE THAN improved upon what you dug out of the boxes from 20 years ago! They look great and it's cool having book-ends to gang up on the Federation ships. Yeah, I was surprised by the glue. It wasn't a lot, but the bolt is on tight anyhow, it didn't take much to lock it up. @electric indigo That's looking very realistic! - MT

-

Well, all the work I did last week was ruined when somehow the glue also melted the plastic around the bolt that was holding it for machining. What a drag! It had to be placed in a vice to unscrew the bolt - it was that bad! I redid it though and with more experience, made it more accurate before having to add in details later. I also made the rings to fit around it and then using existing parts, made the planar panels to go on the mast. - MT

-

@peter Great improvements! Nice use of a wheel, I usually toss 'em! Another method of using matt paints is to buff them smooth if you want to skip using a clear coating. Then clear coat after the decals are. As usual, great work of incorporating a hardware store into your models . - MT

-

@peter Your K'Tingas look great! Wait, that sounds wrong... Nice models dude! @electric indigo Looks like if I waived at him, he'd wave back! Nice n clean gun site too! - MT

-

@peter Your Krylon Kamo colors actually look cool! Especially after raiding the stove top Seriously, they do look good, even though not canon colors. - MT

-

Thanks @CrossAir I'm still thinking about it... @Ignacio Ocamica Your figure is looking great! The primer helps fit it all together. @electric indigo That pilot figure looks fantastic! Great detail in that scale. @derex3592 Your lighting looks just right! I think the colors are spot on! This weekend I started on the top part of the ammo magazine / base of the Oto Melara gun mount. It's the upper part that the turret will attach to. More photos later. - MT

-

@Thom Looking good, Thom! Looks like you're improving on the details too? @Ignacio Ocamica Your details look good and I like the wrinkle you put in the shirt, it adds realism. Originally I spent all that time on the Mk-45 5" gun turret. It just looked huge when I was done. Plus, it's heavy! Mine and the real one! The actual Mk-45 Mod 4 is something like 53,000 pounds - before you add in the magazine and feed mechanism, then ammo. The Oto Melara/Leonardo 76mm Super Rapid is about 16,000 pounds ready to go minus ammo. It also has a rate of fire of 120 RPM - but of course shorter range. With the vertical launch cells up front, the lighter gun is more realistic. I thought two would be cool, so I'm messing around with the idea. I've been undecided and that's why I made a cap mechanism and two turret cases for the 76mm earlier on. What do you guys think of the ROUGH MOCKUP? - MT

-

-

@arbit Thanks Arbit! @derex3592 Great work on your lighting! It looks like the kit seam fit is atrocious. I don't envy the fixes you'll have to do. - MT

-

@derex3592 Ha ha, thanks Derex! My annual styrene budget is VERY low! A lot of the sheet stock goes back to the 1/200 Daedalus build. On the rare occasion I actually buy some Evergreen or Plastruct. In fact, one of the pieces I used this week was about 15 years old judging by the hobby store price tag I removed. Thankfully Hobby Lobby started carry some Evergreen stuff. My favorite place to buy in bulk, when I do, is U.S. Plastics: https://www.usplastic.com/search/?it=item&keyword=styrene This is the cheapest way to get huge sheets. You can buy one or in bulk. They also cut to order for a fee. Shipping may be more than the styrene, it depends. Thin sheets can be rolled into a cheap box. A .040" thick x 40" x 72" long sheet is only $15.56, but you can't roll that up! So it may need to go by truck if you want the sheet intact. - MT

-

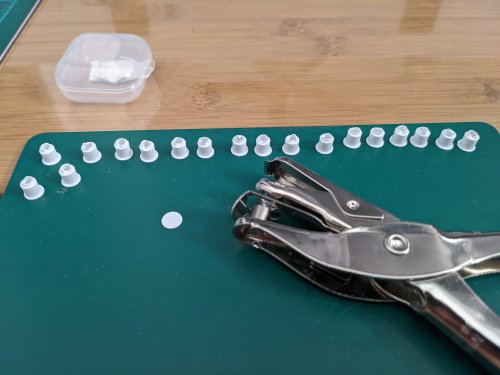

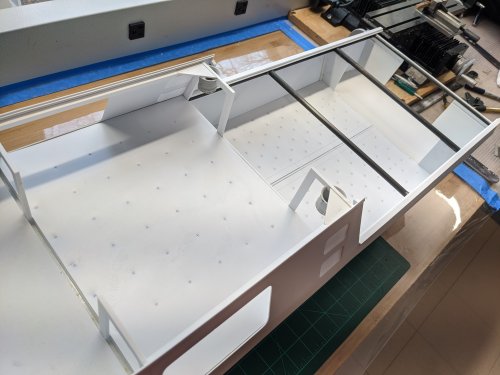

Sorry if this post is image intense, some people like to see process on how you did something. This week we dive into the exciting world of bitts/mooring bollards and chocks! For those non-nautical, here's something new for you (it was for me!). The photos below show how the mooring bitts (or bollards) are used to tie up the ship when docked. Chocks (not airplane wheel chocks) are what the rope goes through. How the two have the same name is beyond me! First the bitts. I used a hole punch to make the top pieces. Then lathed a bunch of tube pieces the same length. When cut-off, they had a flange left over. What I thought was a pain to clean off, ended up being a blessing. I drilled holes in a strip of plastic the same diameter as the flange and used that to keep the tubes aligned on the base piece instead of just gluing them on loose and having to guess alignment. It took me almost as long to engineer the chocks as to make them! They are internally compound curved and I needed 8 identical ones. You just don't get them from Plastruct or Evergreen stock. A set is $40 on Shapeways! Forget all of that! I modified Dremel bit by narrowing the waist and milled a length of 1/4" x 3/4" Evergreen strip. You can just see the double-sided tape holding it down. Then I glued a strip of styrene over the length and milled the sides to slope. Then I used a common router bit to round off the top like a "D." Then the same bit to angle the sides was used to open up the interior. A ball bit and a lot of funky hand-sanding was used to round-out the opening. Two days later all I got was this! Actually 9 bitts and 8 chocks. I did manage to do a little deck work too. The interior flight deck level got tie-downs stamped into it. The lower deck area was made from the old flight deck piece to recycle all that work. I added some access panels to the flight deck area for detail. And here's the whole length of flight deck including the hangar area with bitts and chocks glued down. Now you know more than you ever wanted to about stuff to moor (tie-up) a ship! Thanks for checking in guys! - MT

-

@Rock Your Tomcat is looking good! @Angesdad Anasazi's decals make that look much better! @derex3592 So does the table get cable TV? The interior is looking good! You can include these too: - MT

-

That looks nice and clean! Now you won't be able to look at without that stuff bending! - MT

-

Hachette Collection 1/24 VF-1S (subscription collectable)

MechTech replied to CF18's topic in Model kits

Ha ha! Does the model come with under-wing radioactive meteor ordnance? - MT