-

Posts

4691 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MechTech

-

@Papa Rat Nice fixes to the rear. By the way, use Milliput when it is still wet. It smooths down great with water and your fingers saving sanding, and trim it with blades while still semi-cured. It is good stuff. It just needs practice like any tool. @Urashiman Cool! Getting all electronicy too! I looked through my dad's old Lionel train stuff. There was this glob of aluminum with fins about the size of a small matchbox. I asked him what it was. He said, "A diode"! Technology sure has changed! 😁- MT

-

@Papa Rat Cool! I haven't built one of those in decades! Looking forward to it! @nightmareB4macross Thanks for sharing that! I forgot about that awkward designed head! - MT

-

@Cheese3 Your Misa figure looks good! I lost the eye decals for mine, so she came out looking more like Little Orphan Annie!🤣 @derex3592 Your work areas are looking great! Congrats! @Papa Rat The paint on your -1D looks REALLY good! Nice shading with the color mixtures. @Chas The mods to your SDF-1 made it look much better! @pengbuzz I saw a video online on how to save money model building. One of the suggestions was to use a watered down solution of white vinegar for a decal setting solution. I always thought setting solution smelled like acetic acid. I would give it a shot! - MT

-

@pengbuzz THANK YOU for the tip on the glue. I always thought it was the film that yellowed!? GREAT looking weathering and paint. I don't imagine they're the type of people to take their bird to the car wash!😁 - MT

-

@pengbuzz Thanks for the head's up Pengbuzz! Oh no! We finally "get back" a good stock of classic anime models and their company is not looking good. I've bought from them about three times now and no problem. I hope they're not folding 😕 @SteveTheFish Nice and clean paint! She looks good, especially with the patches as Chas said. - MT

-

@nightmareB4macross That will make a COOL diorama! @Thom GREAT cockpit detail! I'm glad to see a little known airframe get some love! @Chas Your updates are looking GOOD! I don't know the physical difference between the two (I haven't seen Hasegawa's in person), but I believe the most accurate SDF-1 is still the good ole Arii kit, and it could save you A LOT of hassle: https://www.ebay.com/itm/256534032075?_skw=sdf-1+macross&itmmeta=01JSY5XY2NVEGNBSNP5MRHMR0F&hash=item3bba9eaecb:g:owYAAOSwGvRmX3Ch&itmprp=enc%3AAQAKAAAA8FkggFvd1GGDu0w3yXCmi1c08UQTF0BSNandJSTeHQm7GfXKteB94MlA2SxKaFA72So0xVghBq5EjMQcjN94Y4XIeHn7A3JaPyTk3wrTszXaYsRYBmrt4GzRikbL4OfLrHGb%2FtuvnXWTg7GBjdE54zQqOs%2FnQGxX5nncTkx2H5vn4ukBAZC8k5K7ropAb1ewtBuQbspynLWWgZXR1EQejyaPPLPUAdtxccdOgFgrfBZCZX3y%2Fhqa6rICZ61%2BFDAWaLxyq8PHt8hcO1qevRFrrt1xm2M%2FDL2eDPhGBtC5UcqF09Gx6TH8QBH8hGLSikYhqw%3D%3D|tkp%3ABk9SR77h98XPZQ They're so inexpensive now, thanks to Wise Guys, (if you guys haven't shopped their ebay or web site, you're missing out) you can save a lot of trouble. I almost thought of using Hase's Daedalus and Promethius on the old Arii kit, but I don't know how far off they are. It would be nice to have the small vehicles that come with the Hasegawa kit - if they're to scale. - MT

-

@electric indigo Your changes to the legs DO look better! @nightmareB4macross SLIGHTLY! That's an understatement! Is that an old Yammie that you've shotgunned!? Nice work! I hope you felt batter after cutting out all that plastic!😁 - MT

-

Thank you guys! This project is fun and stretching my knowledge of some of the arts. @derex3592 Your new bench looks cool! Not OCD though, just healthy!😁This is OCD (not mine): @Papa Rat Great finish to a new-old model kit! @electric indigo That GP04 is looking good! Are you doing anything extra, or building for fun? @nightmareB4macross The lines on that Valk just look right! MORE accurate lines than the original Chunky Monkey it was. You've become the Weight Watchers of Valks!😅 @pengbuzz I look forward to see what you do! Somebody actually brought one of those into our meeting this month (no hinges though). - MT

-

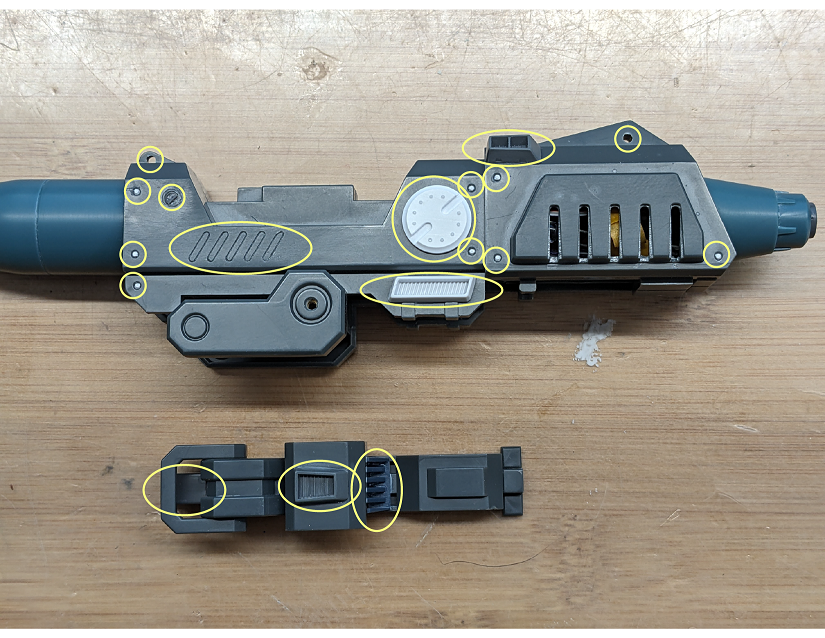

@Papa Rat Revival? That looks like the original mold (which they are still popping out of after 40 years). I've see a couple of Bandai tour vids and they love to show that off. @nightmareB4macross The photo of the legs with all the guts reminds me of the original line art showing the internal components. @Urashiman That's not bad for a test - or a cheap airbrush! The original cannon has very limited detail on it. So I added lots more. Besides cutting out the vents in the side (from last week's post), I added bolt heads to all the empty sockets that they molded in. Kinda weird they did that. I scribed some details and added lots of other bits to it including various vents. There were so many changes, I circled them all. If not for you guys, then for my records to remember what the heck I did. Then I custom made the round plate(s) on the mill. I thought it was a nice touch to an empty space after doing some test fits. Both sides have the same details. Thanks for checking in! - MT

-

@SteveTheFish Your armored 1J looks good in that scheme! I think it's more accurate. In reality, stuff like drop-tanks and gunpods are for the fleet, not an individual. I think armored add-ons would be the same - especially with how expensive something like that would be. The Enterprise is looking good! @nightmareB4macross "This is my evil twin brother. He's also more ugly than me!"🤣 Did I miss something, are those printed hands and fingers? - MT

-

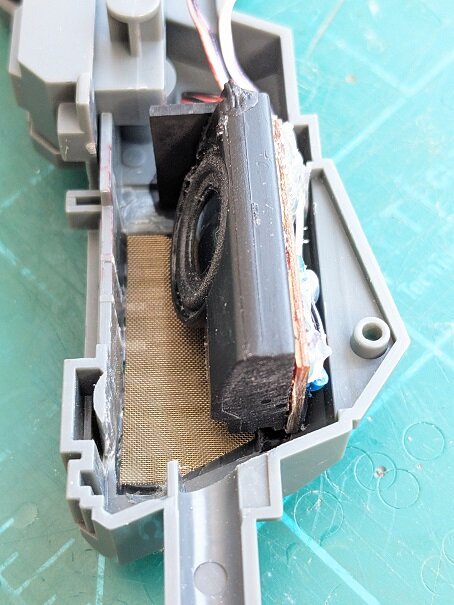

@electric indigo Miami Blassty! The Crocket and Tubs mecha!😅 There's a flashback! @Papa Rat @Thom The BEST CA accelerator, gap filler, or for building up areas with CA is plain ole baking soda (like Arm and Hammer). It's non-toxic and gives body to the area you build it up in. MUCH cheaper too! @derex3592 How did you get stuck with the litter box!?!😁 That's going to be a sweet bench area! Made some progress on the Dougram kit. The switch for the main gun (two position - up and down) is much smaller than the original switch that came with the "missile switch" assembly. So I had to make a spacer for the hole and a new cover to go over the top. I've have the guts of an "electronic sparkler" sitting around. Originally I bought it for the fiber optics that came out of it. Now the rest of the guts are going to make the light flash and give it a little pulsating white noise. Better than just a light. Radio Shack (which has so many stores closing down - including the one by me😕) had these cool pink LEDs. More anime realistic and not plain ole white or red. Looking for a good location to install everything, the gun itself seemed good. So I milled out the vents for detail and the speakers to vent through. I took coffee filter screen and cut some pieces to fit into the slotted areas. And everything neatly installed. 1. The PC board was shortened and re-soldered with new wire runs. 2. A recycled laptop speaker was used instead of the cheap stock unit (and sounds better). 3. The PC board was glued to the speaker to keep it all a small package. 4. The ABS speaker was glued to the styrene bits by using acetone on the ABS and Tamiya cement on the styrene. Both joints were well soaked and put together. You can weld unlike plastics together - sometimes. And the whole thing put together. It looks and sounds pretty cool now! Thanks for checking in! - MT

-

Thank you guys! The build is coming along slowly. @Chas @pengbuzz Thanks, Chas! I've been watching some of Adam's videos already. I saw the Voyager model and thought of Pengbuzz and his superior masking tape skills. The builder used tape extensively in the Voyager prototype build. - MT

-

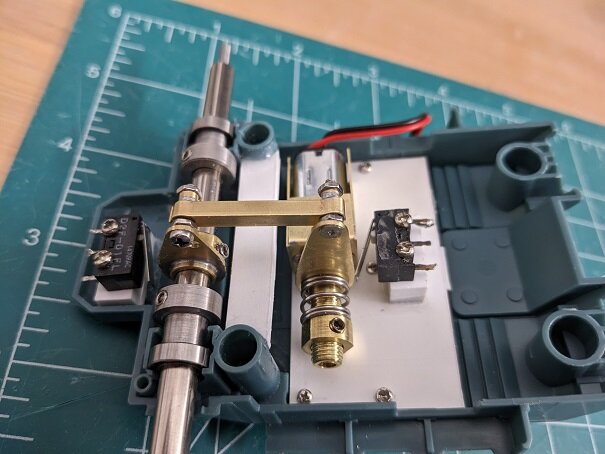

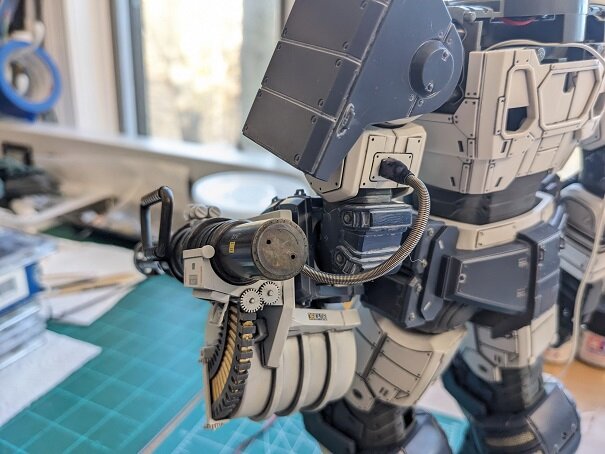

@pengbuzz That Fett figure came out AWESOME! You made it BETTER than new! @Cheese3 You are DEFINITELY going for the 80's urban camo scheme with those colors! Either that, or an original Van's tennis shoe design, also from the 80's! @Papa Rat You made the space pickle look great right out of the box! I forgot about all those ugly engravings in it. If I even build my Zen fleet kits, it will take A LOT of epoxy putty to get that one to decent proportions! But you did it justice outa the box! @Urashiman We give you credit for trying to breath life back into your airbrush! Sorry man!🥲 I haven't been slacking off, honestly! Just not online much. Now on to the backpack... The main backpack (below) is roughly 3" x 4". The backpack cannon is HUGE at 11" long - but thankfully hollow and fairly light weight. Since I'm motorizing the rotary cannon, I thought the backpack should be motorized too. The mechanism to rotate the cannon over the shoulder, and back upright is what you see here. This is the "servo" motor and the friction clutch which will protect it form forced movement. A spring maintains friction, but prevents direct coupling to the motor gear-head. This motor is more powerful and quiet than an actual servo, so that's why I'm going this route. It's also hard to bust up steel gears. And here's everything put together so far... You can see how the friction clutched arm connects to the cannon's main shaft (which sits on bearings). Carefully positioned micro switches will cut off the motor - even though the clutch also slips when it can't go any further. Lot's of brass work and soldering. That's it for now. Thanks for checking in! - MT

-

Sorry guys, been too busy to get on line! Thank you for all the compliments and likes! @arbit I'll have to pose it with a can or something. I'm working on parts for the weapons backpack now. @Big s There are those 30 minute mission bases, but they are narrow and kinda short for a lot of mecha. I saw these and the color is great and being styrene is a bonus! @Papa Rat That 1J came out great! I didn'y have that on my list, but may rethink that! @Cheese3 Make that old pod look good!😉 The seams on it are tough. - MT

-

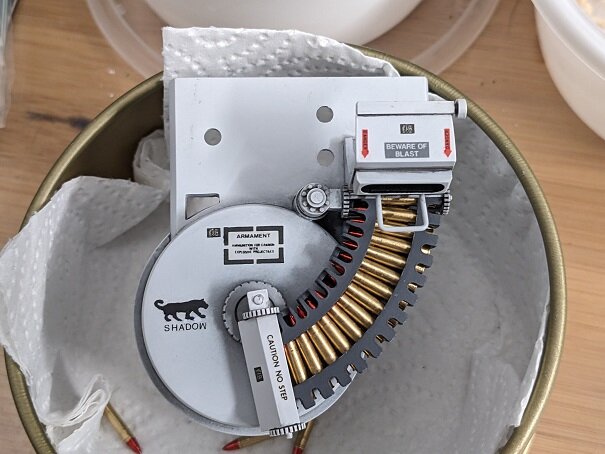

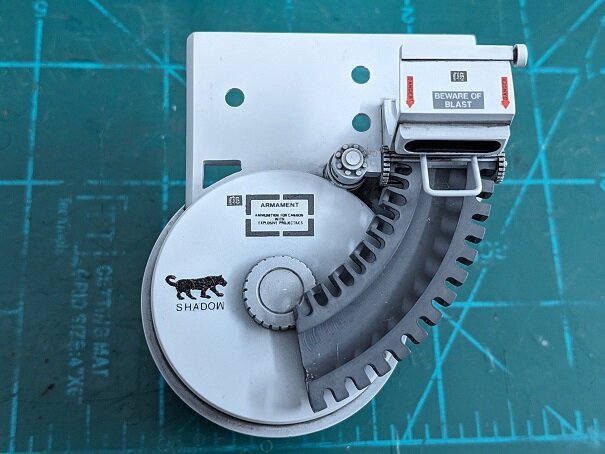

Sorry guys, it's been a while! Too long! I literally ran out of "likes" for all the cool builds you guys are doing! Sorry, I'm also short on time to post comments, so I'm squeezing this in on a break. You guys have been building some AWESOME stuff!!! In trying to spend more time with my wife (so she's not a "hobby widow"), I'm working on Gundam kits in the living room while sitting with her. They take no special tools or stinky glue work just to knock out for fun. The serious scratch building work is taking longer - like weekends only now, so progress has been slow on this build. Speaking of my wife, while at Homegoods with her, I found these cool looking, swirl-blue, water-looking plates. They'll be AWESOME to make under water or over-head water back-drops for your Z-goks or other aquatic mecha and subs. They are styrene so are easily cut, glued or heated up to shape. Just sharing! The Dougram rotary cannon is FINALLY done!!! 1. I took the re-milled Tamiya 1/35 Sherman shells and clear coated them with clear nail polish, then painted the tips red with a fine Sharpie marker. The red isn't canon (ha ha, get it), but stands out in this sci-fi build. The day of and after our cat Shadow was diagnosed with cancer, I was building and painting this cannon. So I decided to dedicate it to his memory with a decal and combining all those tiny identifier letters at the bottom of decal sheets to make his name. Plus, "the Shadow Cannon" sounds kinda cool! The cat decal splintered like crazy! But I fixed it and painted parts. Then in went the ammo with Evergreen clear canopy glue (white glue) to lock them all in snug. The cannon body and site parts got painted and decals as well too. To go that extra mile, I lathed some short 1cm tubes to fit snug into the cannon barrels and rammed a Dremmel cutter down the center with the lathe to "rifle" them. I added a black wash to help the grooves stand out. This photo is with an old binocular lens to magnify one of the barrels. It took SEVERAL photos to get this visible, mostly in-focus one. Then all assembled and weathered with Tamiya Panel Liner, paints, Tamiya dusts and a regular Prismacolor "Silver" colored pencil to "chip" it. And cycling through a couple of times (slowed down for the GIF creation)... It does rotate clockwise from our view. Again, the GIF goofs some videos up! Thanks for your support and checking in everyone! - MT

-

@Shawn Consider this a "LIKE"! Aha! So those (now defunct) LS brand model kits/molds (which I have never seen before - THANK YOU!) must have been bought by Imai who sold them as 1/72nd scale. I knew they were 1/100th, the pilot is way too small! I only recently heard of LS as I bought a TINY model of the BD-5 by them at a hobby convention. It's all starting to come together now! Thank you again! - MT

- 14034 replies

-

@derex3592 @Papa Rat @Big s @Thom @nightmareB4macross @pengbuzz @Radioguy @Urashiman @arbit THANK YOU ALL for your condolences, thoughts and prayers! They're much appreciated! The long list above is one reason I posted Shadow's death. You guys are an awesome support group of sorts. I also know most of you have "building buddies". It's cool when someone gives you nice feedback on your model build, it's another when they support you in your time of loss. This is the closest thing to me for social media. No time for that AND building - so model building it is! Besides, nobody wants to see the burrito I had for dinner last night on my social media account! Funny thing, we needed a new cat tree, so we decided to buy a new one. We went to PetCo and they had a kitten adoption day! My wife couldn't even look at them! They had tiny trees, so we went to PetSmart. They ALSO had a kitten adoption day! My wife laughed not being able to run from the inevitable! I actually ran out of likes for all the COOL stuff you guys are building! I'll try to make updates in the week. I gotta run now, but THANK YOU ALL AGAIN! - MT

-

Why isn't that in a frame or at least a bag! It's looking pretty worse for wear too. It's IS COOL though! - MT

- 14034 replies

-

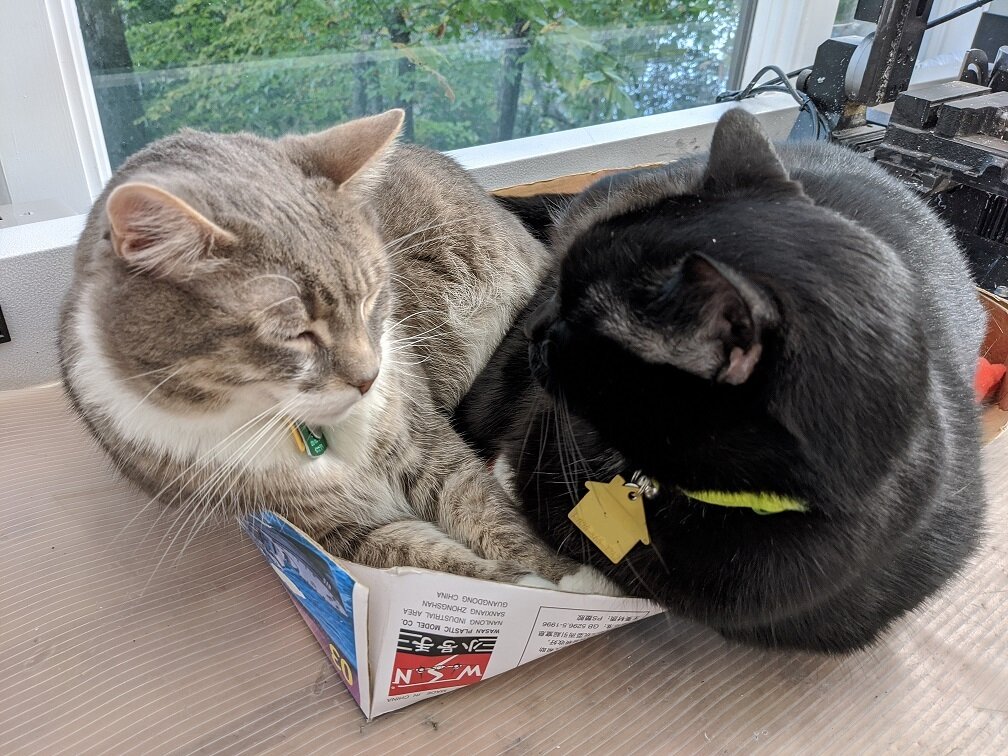

Hey guys, I've had two modelling buddies, "Butters" on the left and "Shadow" on the right. Here they're demonstrating just how much you can really squeeze into a model box! Here, they're on my workbench and "help" me build, so the photos are relevant.😉 Butters got his name from the shelter we got him from, and Shadow got a new name of Shadow because he shadowed us all over the house - not because of his color. In fact, we stepped on him several times the first week because he is the definition of stealth and got under foot. He was a great modelling buddy! Sadly, it's with a heavy heart that I announce the loss of Shadow. He got cancer in several organs and was not eating or drinking. Over the past week and a half he was X-rayed, ultra-sounded and given anti-biotics in addition to a drug that makes you hungry and eat. Nothing worked except the ultra-sound showing the cancerous growths. Shadow went from being a hefty 20 lb cat, to losing about six pounds - a LOT for a cat of any size. We don't know how long he'd been losing weight. Finally, he had to be put to sleep. He couldn't eat or drink, he was drooling, his nose was running, and all his organs were failing. The poor guy was a fraction of his original self. It all happened quickly and surprised us and the vets. He was well treated and loved right up to the end! Last night we brought him in for his final vet appointment and sat with him on the floor as he was laying on a big dog pillow. I'll spare you the details, but it was like Jesus took him before the poison did. He didn't move or blink beforehand at all, like he was already gone. He knew what was going on and had a peace about him the whole time. But to leave this thread on a positive note, he was a hilarious buddy, especially working on projects laid out on the living room floor. He literally made himself at home! How anyone could sleep like that in the photo below is beyond me! He helped keep my instructions flat and make it "fun" to find parts on trees he was sleeping on. Shadow was recycling minded, always helping us crush boxes for the recycling center. I also think he had a small cat mindset in a large cat's body! You don't have to fit entirely inside a box to curl up in it - do you? He loved the little spray booth someone gave me when they moved. Maybe because he actually fit in it! Shadow will REALLY be missed! This is not meant to be a depressing story, but some good model building memories with my buddy. Make sure you all appreciate your buddies. Time evaporates about as fast as model cement! - MT

-

@Thom Thanks. Thom! @Papa Rat The paint is looking smooth on that head. @F18LEGIOSS2 I haven't tried pastels or charcoal, but that sounds like a great idea! As @nightmareB4macross mentioned, with water and soap (similar to Flory's, but they use clay too) would probably work. I have a model I may do where solvents can't be used in the final wash. This might work! @Urashiman The theme to "Magnum PI" plays in my head when I see those photos.😎 That's the original "Loach" kit of a Vietnam era version. Loach as in the speedy and slick fish that's hard to catch. It probably has the aerodynamic pod and mini-gun (gatling gun) in it, unless they cut it off the sprues. I built that kit decades ago! The fit frustrated me too, but I always loved that sleek design. In my childhood home, my neighbor had one and we didn't know it! He invited us on a flight one Easter Sunday. He had it to work his silver mine down in Mexico. It had to be flown and ran up every week or two to keep the turbine seals moist with fuel and oil. So, he invited us out for a flight! It was cool! He was like, "Hang on to the doors, don't let them open in the opposite direction, those hinges cost $1000.00 each (that was back in the 80's). I met a guy who was shot down TWICE in those things back in Vietnam! One time the pilot just got the bird down safely before dying. He got struck with a cannon round! He had some crazy stories! - MT

-

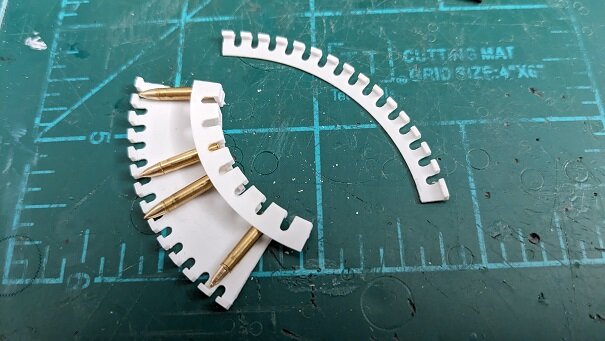

@SteveTheFish If you're going to strip the paint off that, "LA's Totally Awesome" (at the Dollar Store) is one of the best and safest agents to clean all that off. You just need to wash the residue off with soap and water. It won't attack glue or the joints either. Have fun with it! @electric indigo Cool Photoshop of your SLUF and paint of your Luftwaffe "What If"! @Wewyllenium Sweet metalics and colors on your paint job. @nightmareB4macross It may not be for a couple more years at this rate, but you're gonna have to have a party when you finish that! Cool intake covers! Years ago some hobby shop was trying to get rid of their Tamiya brass ammo for various models. So I bought a bunch of it on sale KNOWING I would use it some day. So maybe its been about 25 years now, but I found a use for it! The diameter of the barrels and the size of the cannon body dictated what size the ammo would have to be. So I took Sherman 75mm brass and had to machine it down to a shorter length. They make this brass on computerized lathes that cost thousands of dollars. I had to do with a couple of dollars worth of ground tool steel. Thankfully my idea worked! Next came the ammo chute to feed the cannon. This is where photo etch would be king! But I don't have the stuff to do it, so styrene was CAREFULLY used. The parts are THIN and clean-up after milling them by hand took hours. Here's the parts (one side glued together) and all the pieces glued together along with the cannon body treated with "Brass Black" which is an acid. It beats painting and is much more durable. The ammo chute still needs more work on it along with the drum magazine. That's it for now, thanks for checking in! - MT

-

@nightmareB4macross That is BEAUTIFUL engineering and work on those pieces! @F18LEGIOSS2 If you have Acetone, that is one of the BEST cements for ABS. It is super thin and dries FAST, so watch how you use it if so. - MT

-

@pengbuzz Thank you! WOW! Talk about brain surgery!!! That's some serious sculpting. Looking awesome! I can't sculpt people. Maybe I should try a glue gun to add "hair" to my balding head. I bet I won't need much hair gel.🤣 @electric indigo I don't know about that, but thank you! Yeah, SLUF really isn't accurate; but yours is (see what I did there)😁. It was one of a few planes to actually fly properly and be on production schedule as planned. It had a good all around record. I guess that's why the AF purchased them too. @nightmareB4macross You're right, they no longer are the legs of a '55! They look younger! You ARE a plastic surgeon!😉 @Cheese3 Those are definitely the girls my mom told me to stay away from! Great looking paint and details on them! - MT

-

Cool! Must be fairly tiny. - MT

- 14034 replies

-

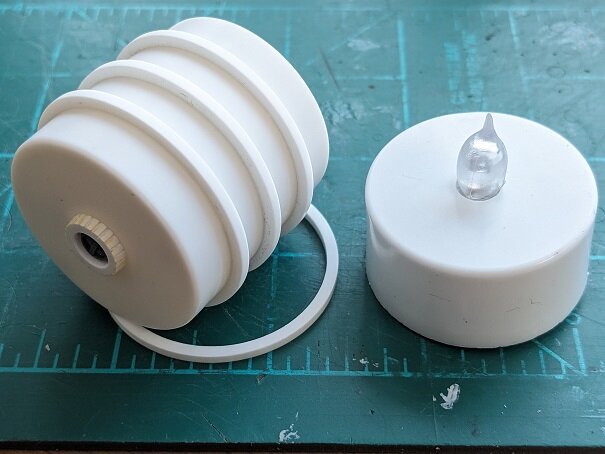

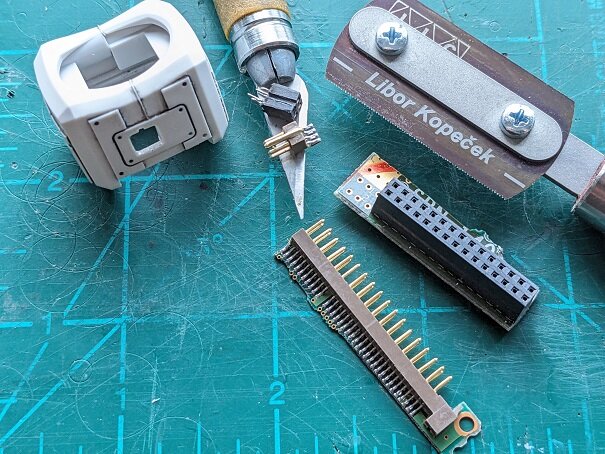

@nightmareB4macross AWESOME improvements to that '55! We can't call it a "Chunky Monkey" anymore.😁 All of those details and added "gimicks" look MUCH better than outa the box! @Cheese3 That Falcon came out great! Your cat on the other hand has that look of "Not another photo! Leave me outa this!" 🤣 Yes, it's cool having everything in the same scale. @Urashiman Cool start on that Valk! @electric indigo Your Corsair came our BEAUTIFUL! Congrats! No bias here😎, but I'm glad to see one in the Air Force livery. They're lesser known, but heavily used. For the 1/35th Dougram... Things are coming out WAAAaaaaay slower than expected with finishing the Dougram. I'm behind schedule for the model show near the end of Feb, and I haven't even started the backpack weapons yet! Oh well! Most "portable" Gatling guns have a handle on top as did the stock one. So I did one, but the handle stuck out A LOT. So I scrapped it. The ammo drum was made of two LED tealight candles cemented together. I milled out rings to go around it for strength and to attach it to the shield. An old brass flashlight was cut-up and turned into the cover for the gear case. It had threaded ends making things easier to complete. The problem was soldering it to the main body (that old piece of hose nozzle). So a wooden guide had to be lathed to keep the parts aligned and concentric. Thankfully it worked! Then I added "bolts" cut around the edge for detail. This can come apart for maintenance, so the end cap screws off. I etched in an arrow to show the direction to open it. Then I realized if it gets stuck, there's absolutely NOTHING to grip it with. So I drilled two holes in it to get tweezers into. The problem, I made a "smiley face". Oh well. It's a happy cannon now! The gun and ammo drum together. Since this was all an afterthought, I didn't build the wires into the model. So they had to be added in afterward. The gun also needed to be detachable as the original is. So old PC board IDE connectors were cut with a razor saw. They work great for this. It's the only way I know to find connectors this small. So one was made with a "fifth pin" glued to the outside to ensure it's keyed for the battery poles to align correctly. The female fits flush in the arm and the male is on the cannon. Add a glue gun and old detailing spring and everything came together while being fairly rugged. Other details are being added to the cannon case for realism. That's it for now, thanks for checking in! - MT