-

Posts

525 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Nyankodevice

-

-

-

-

-

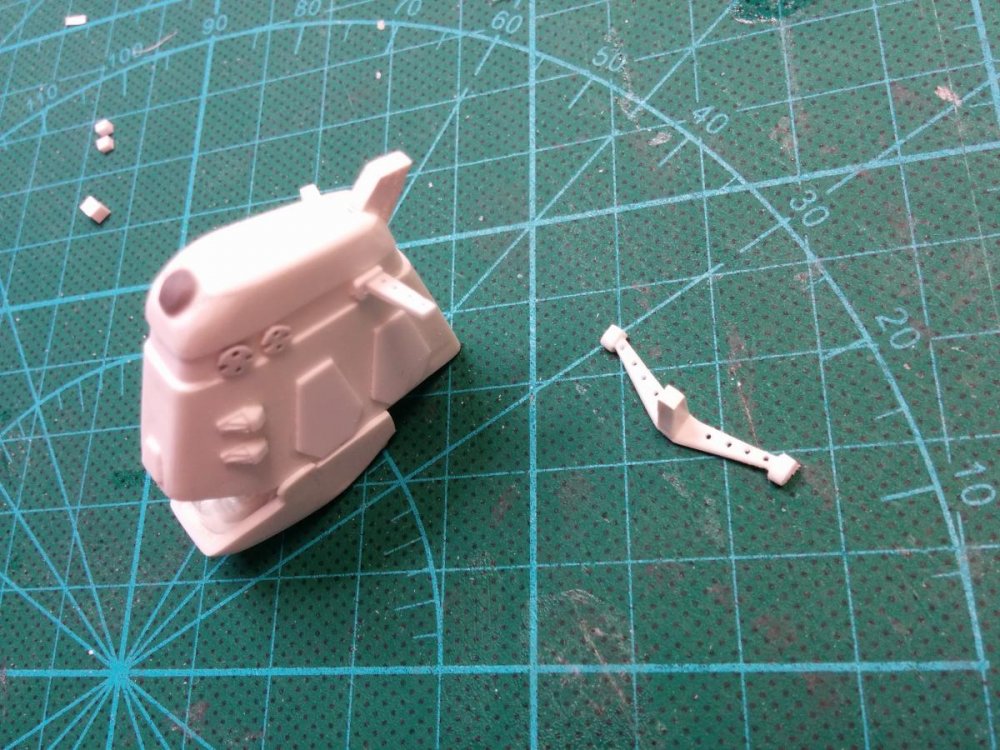

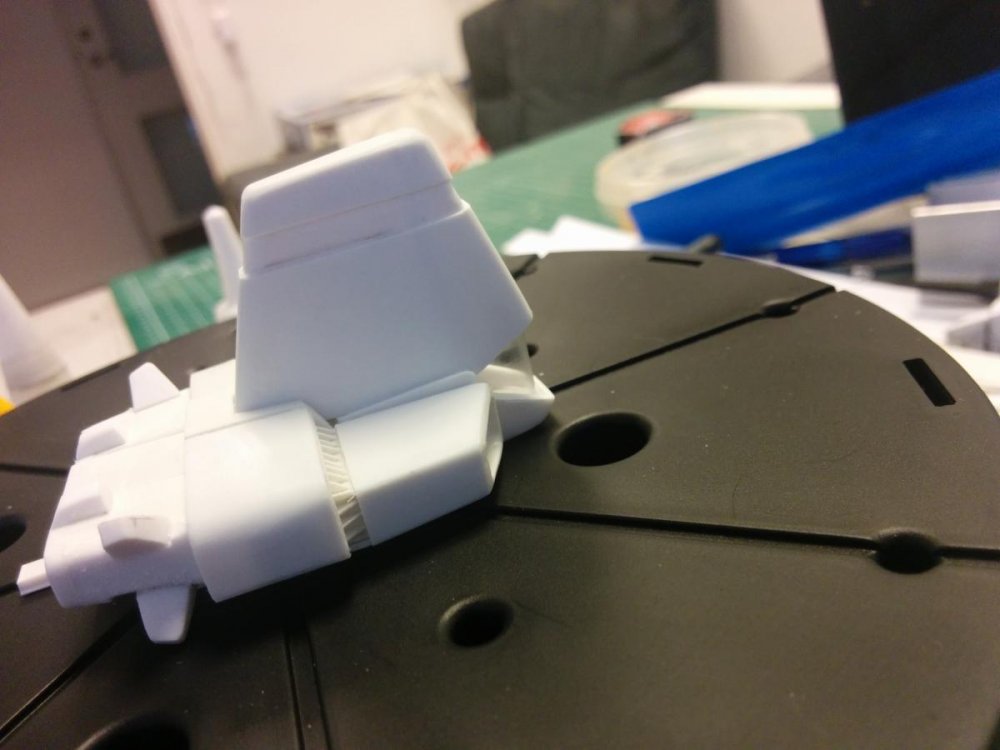

Very impressive. I would love to know how you achieved these curved surfaces. It almost looks vacuum-formed!

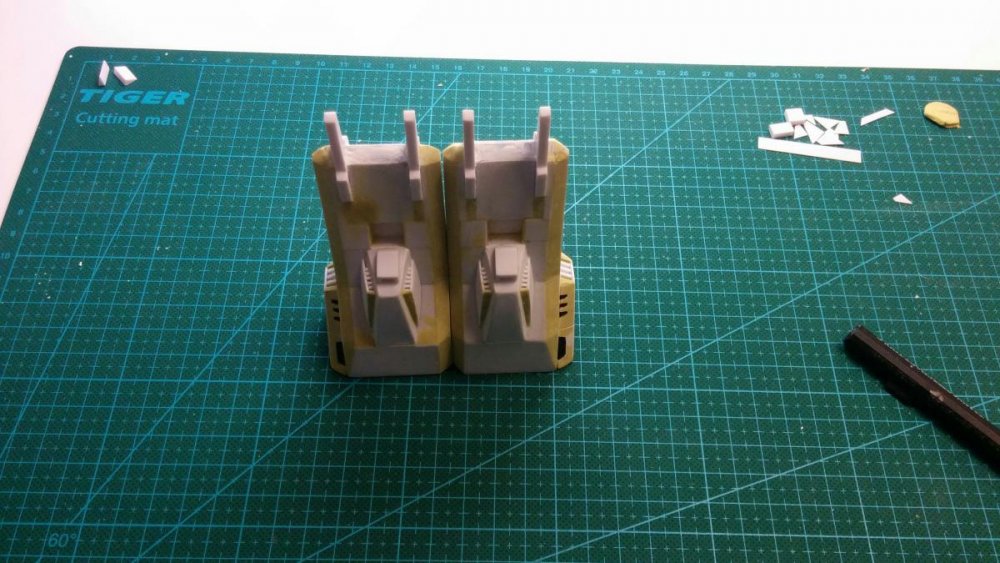

it isn't vacu-formed.... don't have the tools for that... yet

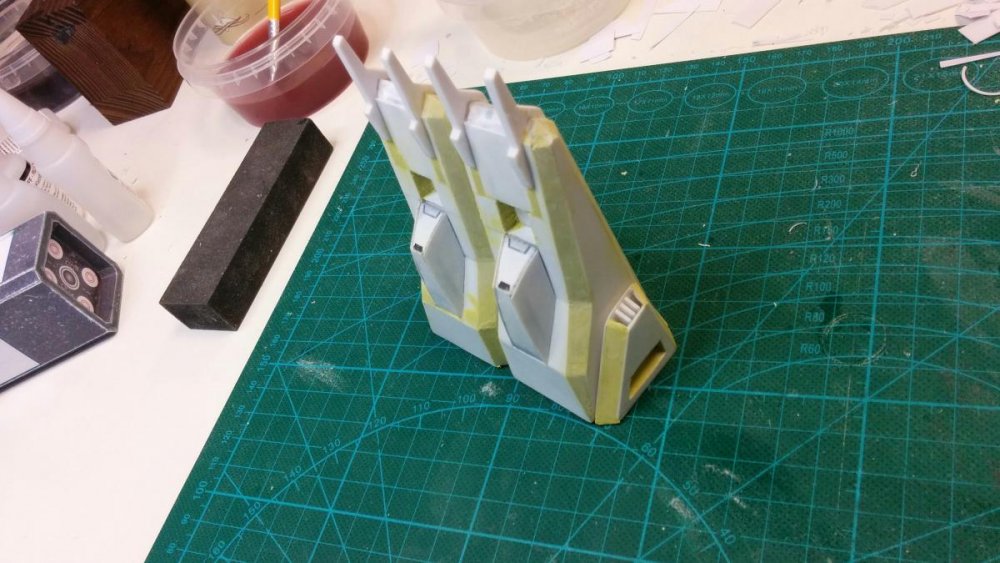

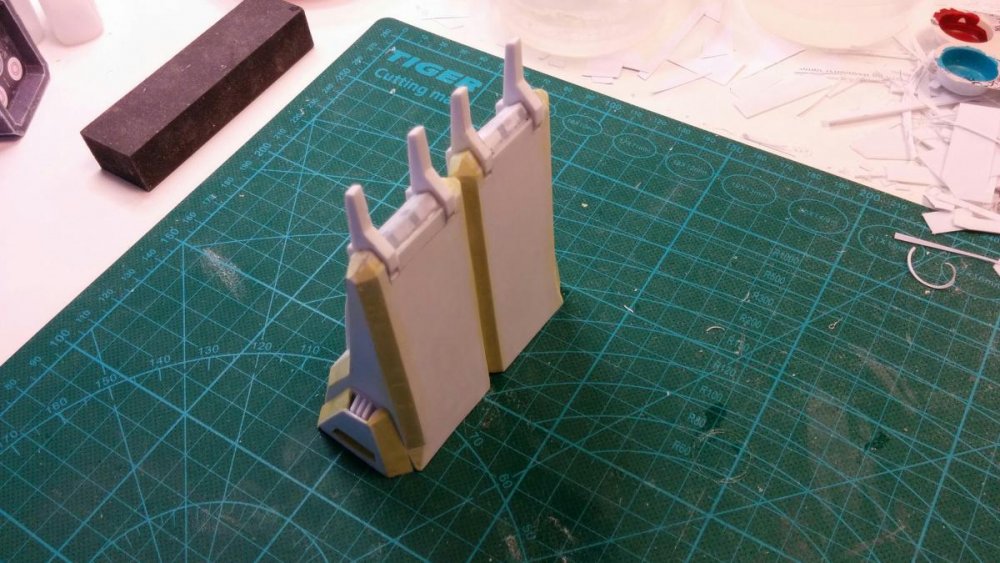

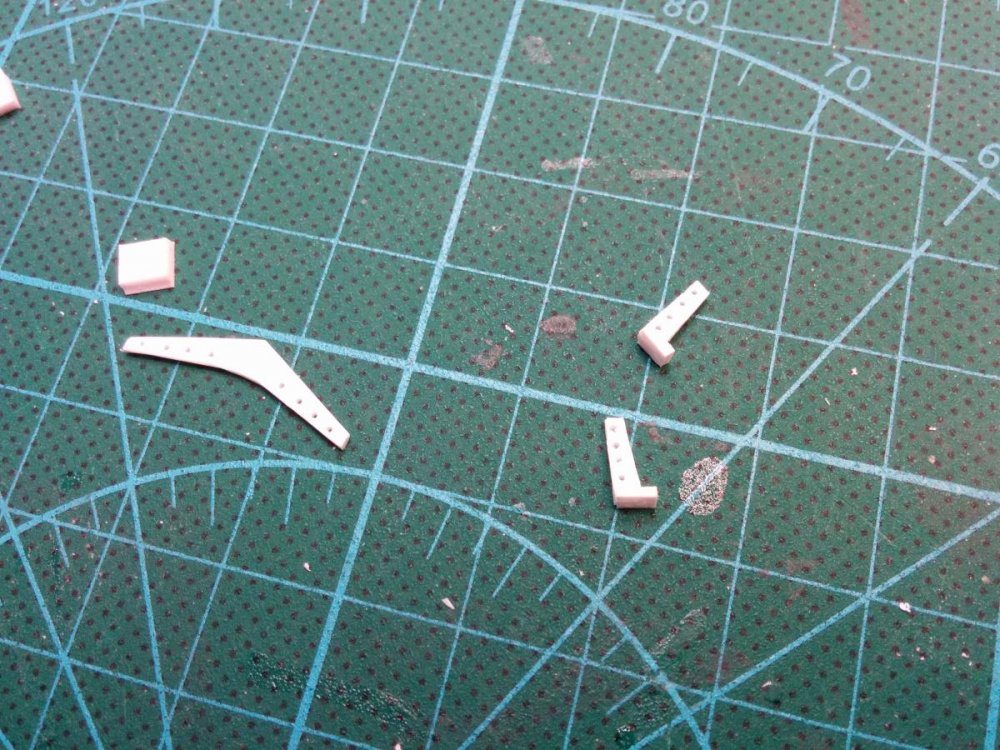

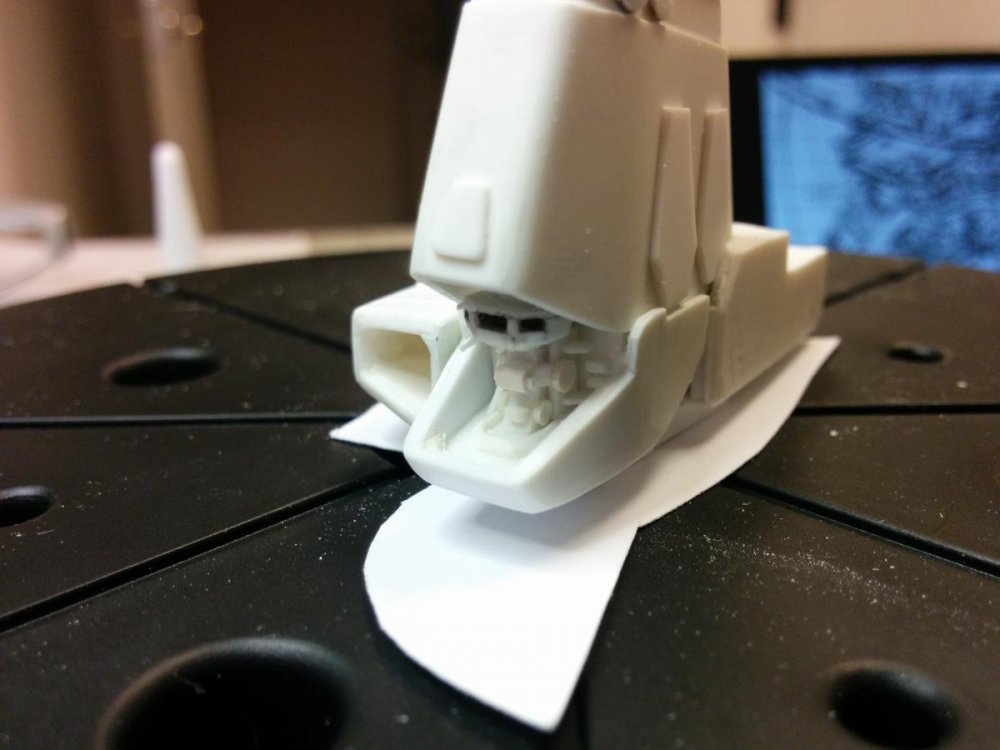

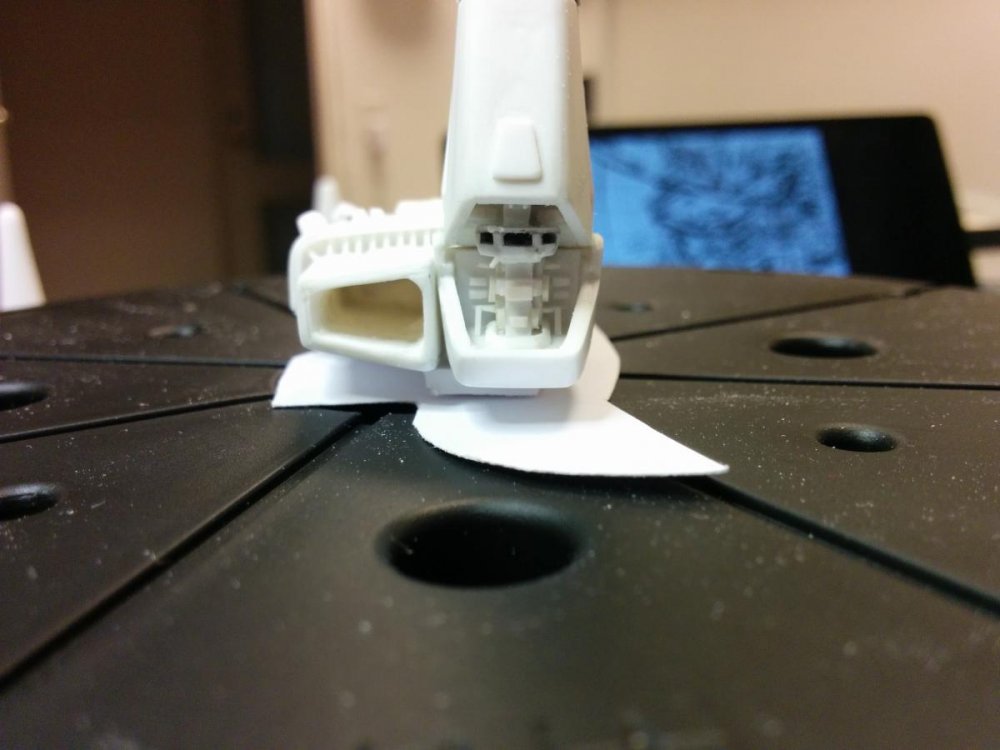

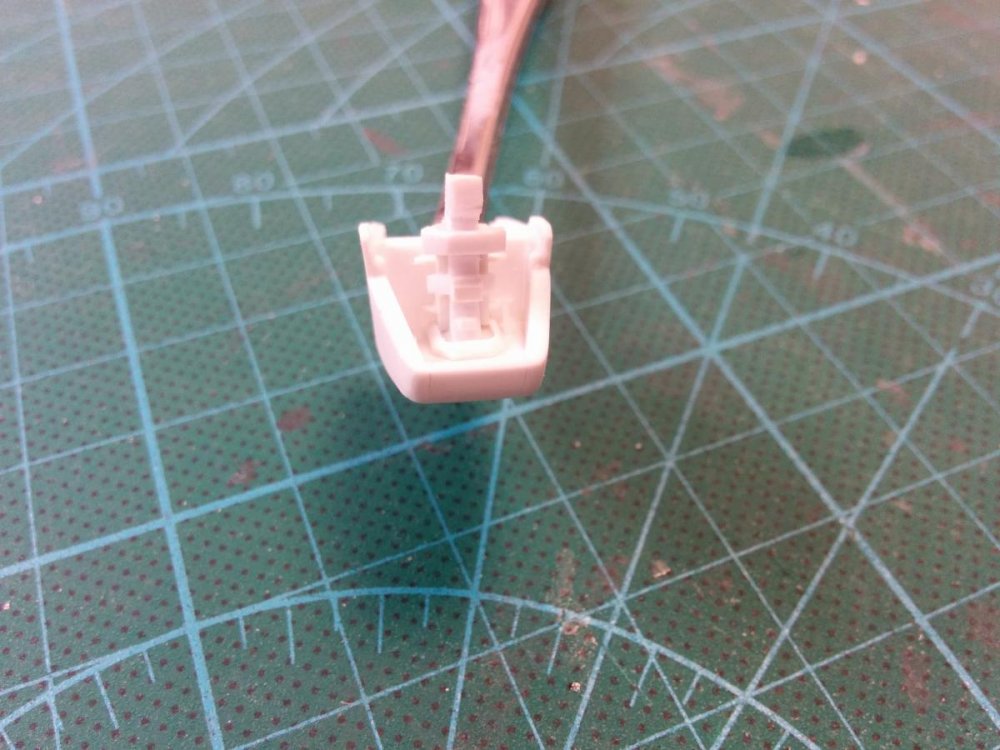

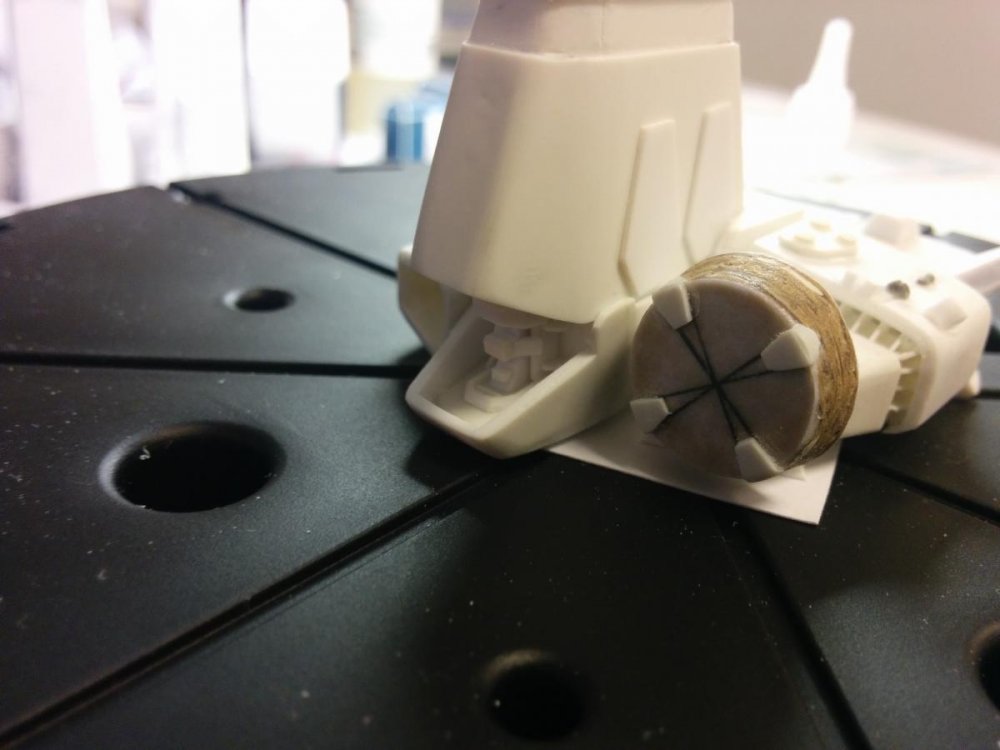

its put together in sections then sanded round to fit the curve i need..

further more there's two layers of Styrene on that bridge, the inner layer at 1mm thickness

and the outer layer at 0,5mm

-

After you make your SAP, you can make kits for the rest of us!!

that is a real possibility

Don't forget the drones for it, either!

right... mustn't forget the drones

-

i will buy this...

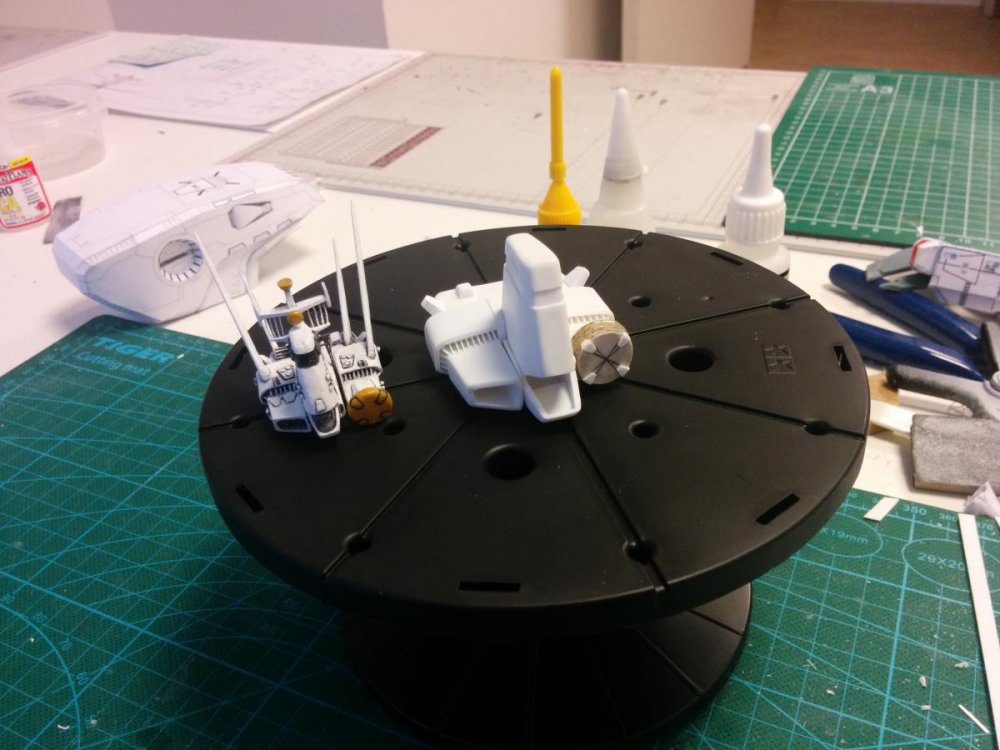

then ill make the necessary changes, for it to look even better...

then ill make a SAP pack for it...

-

dang cant come this year either

ill have to wait for '16

-

That looks awesome....

any chance you'll make a 1/48 Bike for my VF-19?

-

-

That's absolutelly awesome..

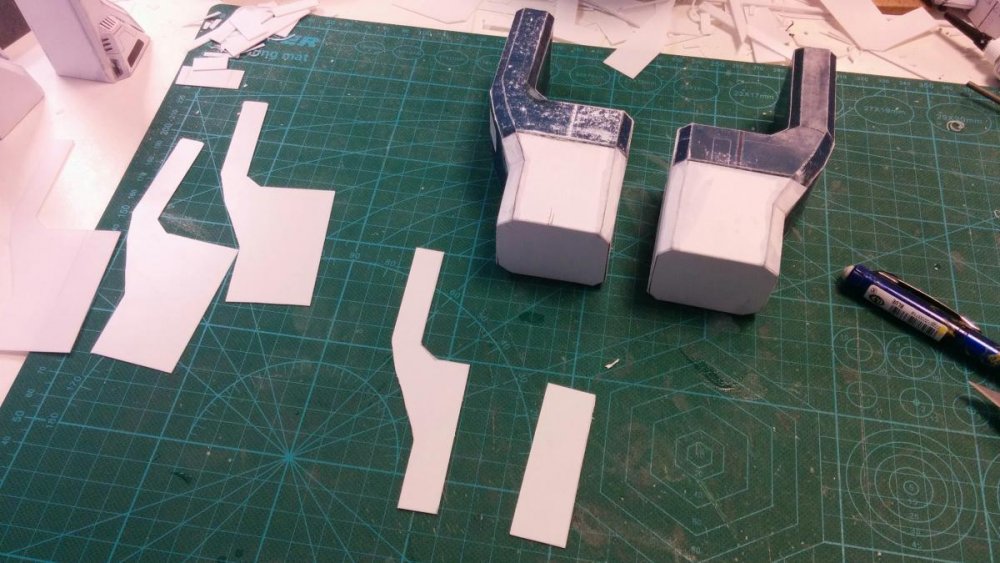

Care to share from where to get the styrene sheets in bulk?

well i buy mine through a danish shop, which is reselling from this company: http://www.raboesch.com

standard sizes: 194 x 320 mm / 7,6 x 12,6 inch ranging from 0.3 - 3.0 thickness (1,59 USD - 5,97USD)

plus many other options and larger sheets......

dunno if theres cheeper alternates out there....

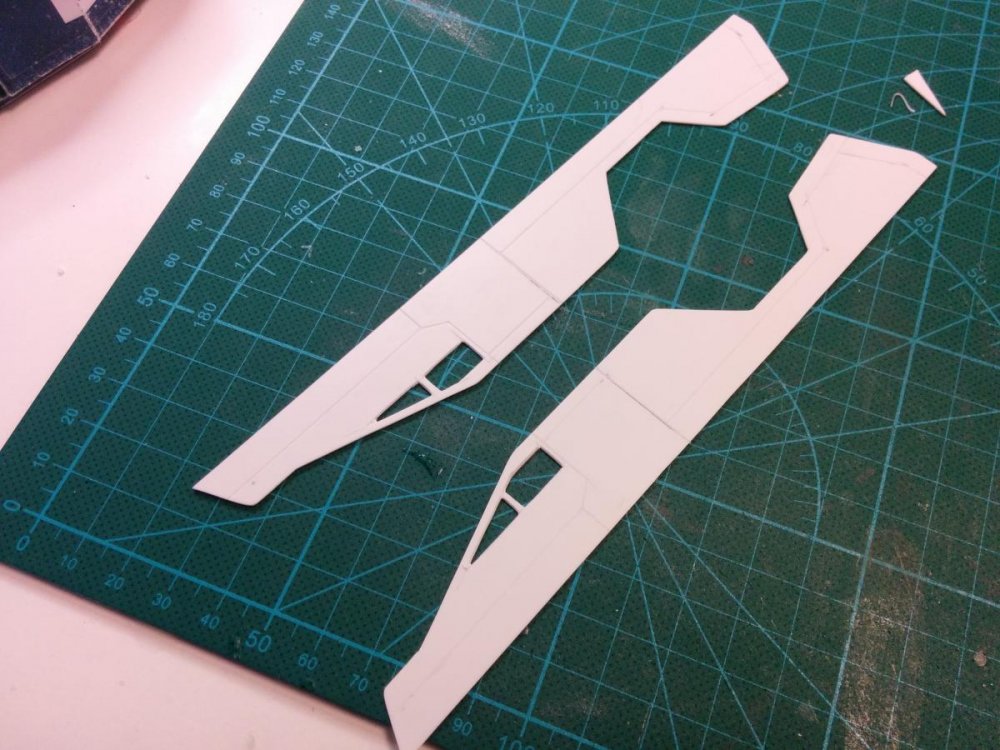

my preferred sheet thicknesses for scratch building are 0.5mm 0.75mm 1mm 1.5mm

hope this helps!

-

-

-

Has anybody ever thought of making a, say, 1/350 display piece of the SDF-1 bridge?

that is actually something i have thought about my self....

maybe i should add that on my to do list

-

-

-

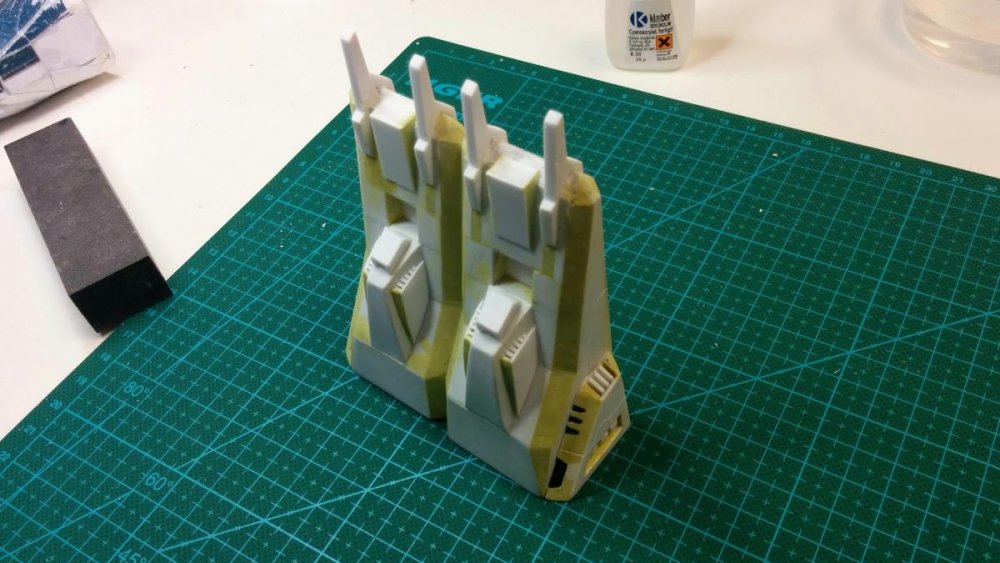

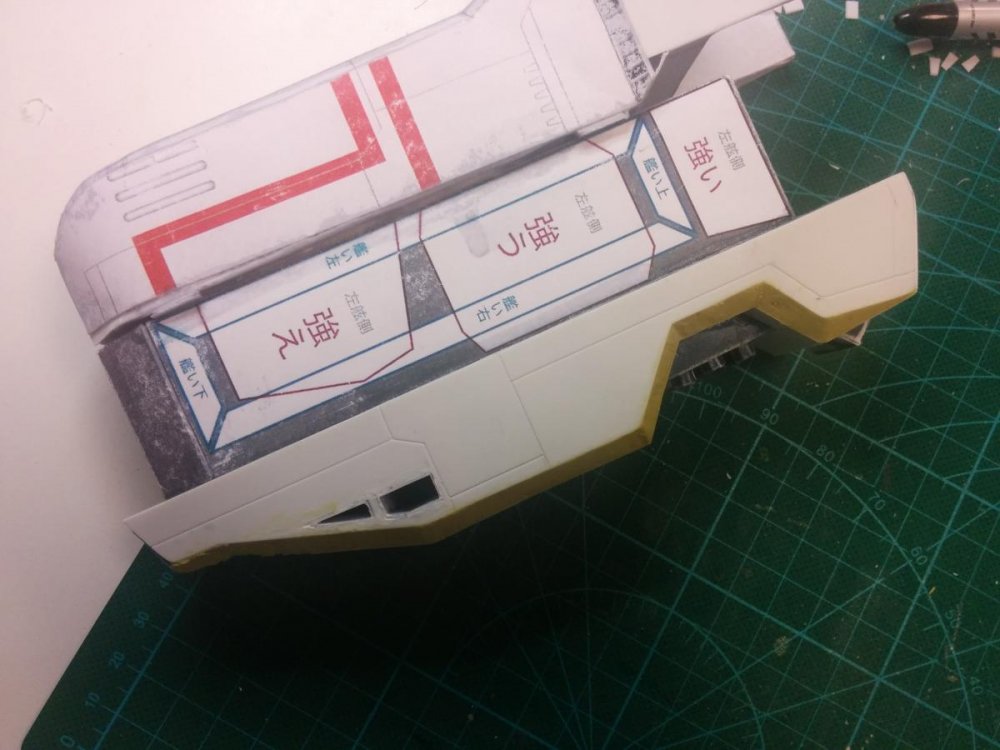

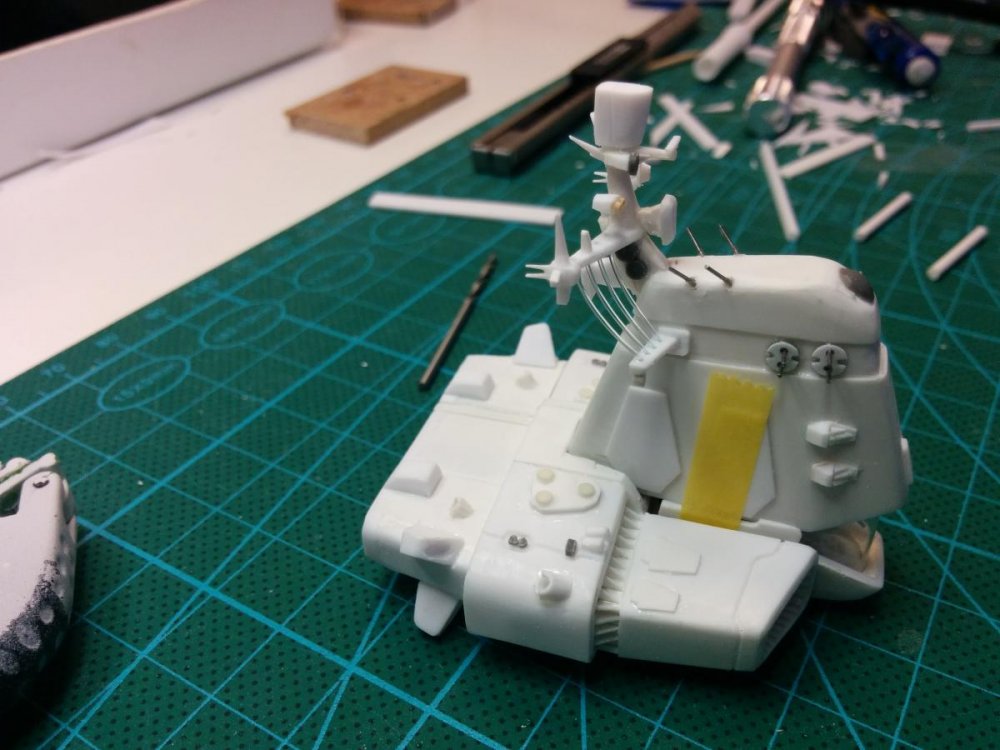

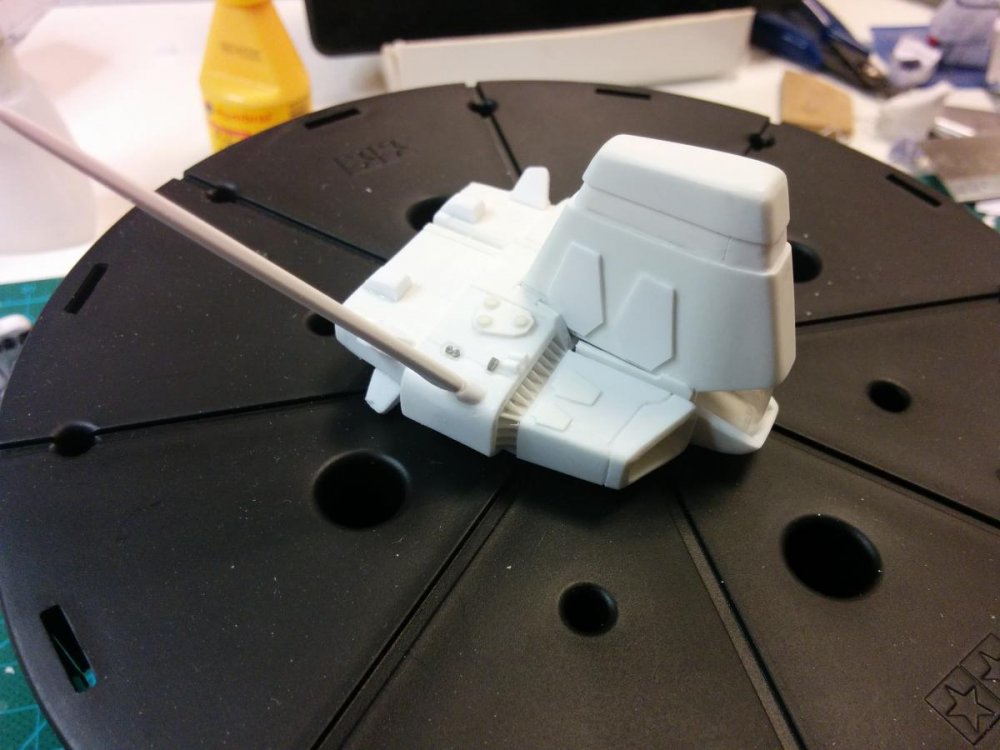

You, sir, have an incredible amount of patience! That is turning out absolutely awesome!

thx

patience yea, but more so, stubborn!

patience yea, but more so, stubborn!You Sir are a Modeling Wizard!!!

thx, ill keep conjuring up more details

-

-

Wow!

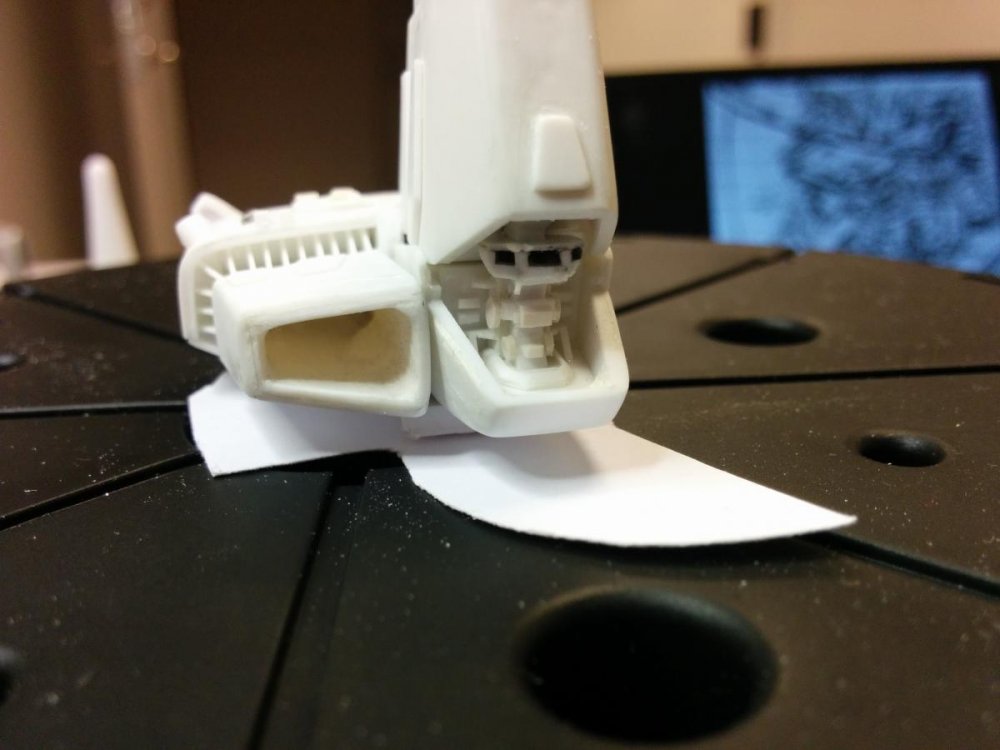

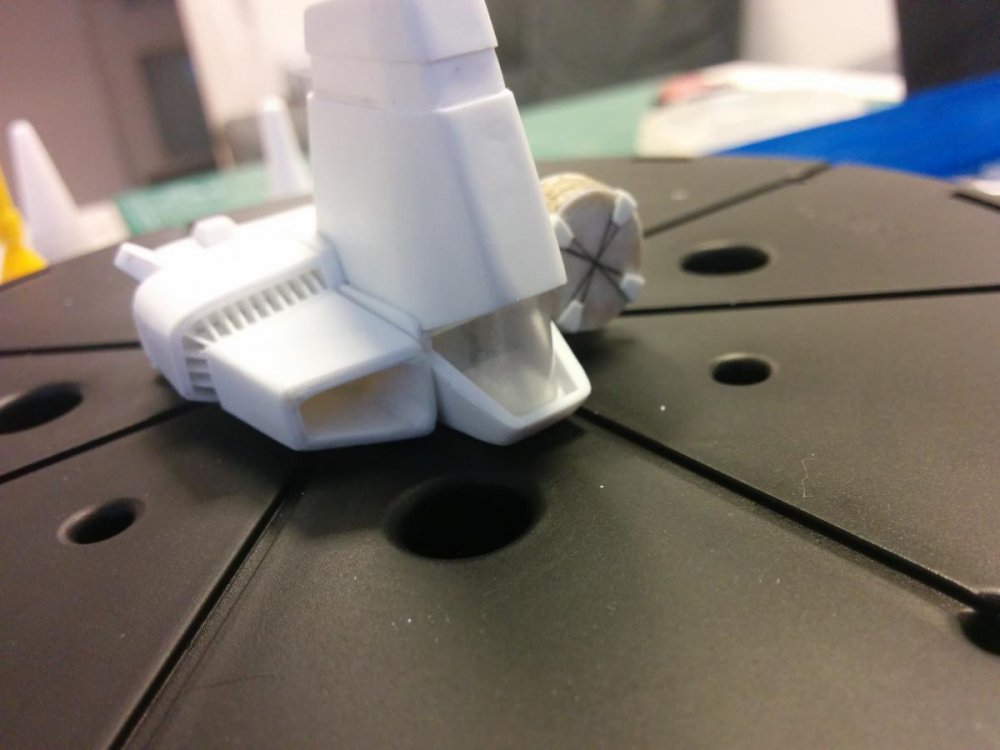

So are you using styrene now and not paper for some of the bridge?

well i decided early on that i wouldn't limit my self to paper....

paper is great for alot, so is styrene... so whichever works best for any given task, i use!

-

-

-

-

-

-

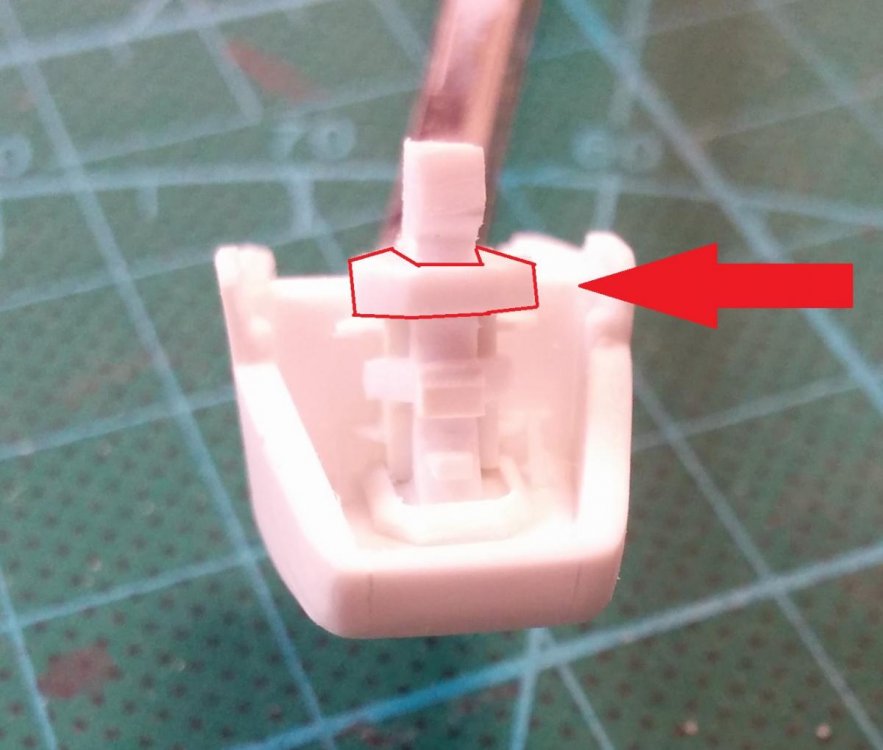

Hey - where can I get a hold of syringes like that? I need syringes with large needles like that for applying different substances.

i would suggest you search on Amazon for Industrial Syringes with Blunt Tip Needle

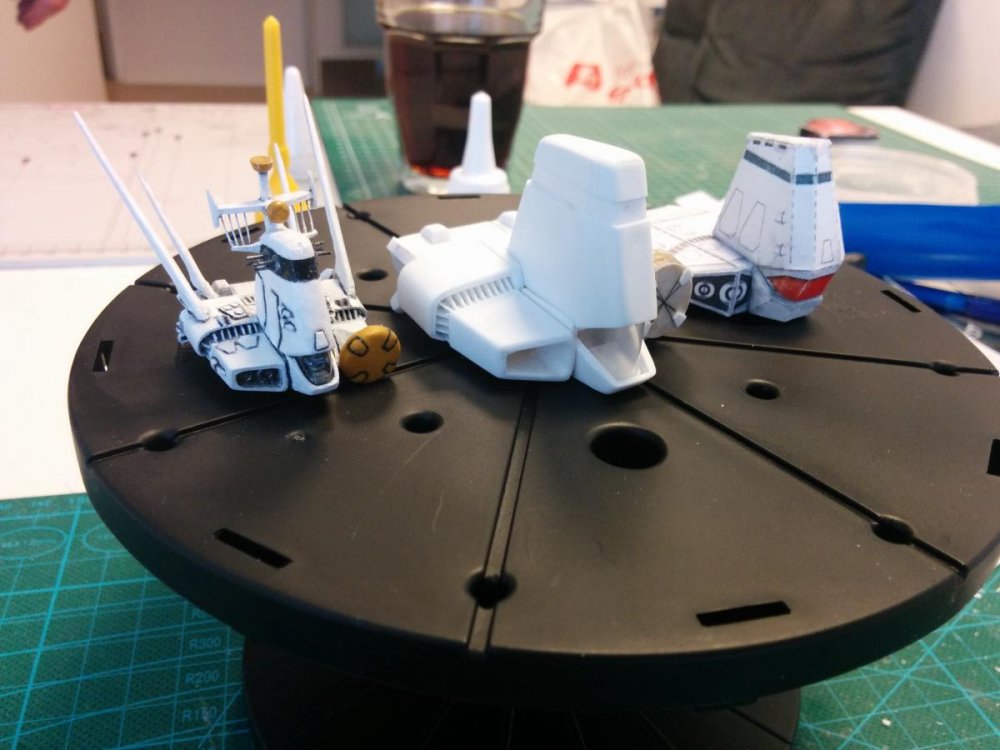

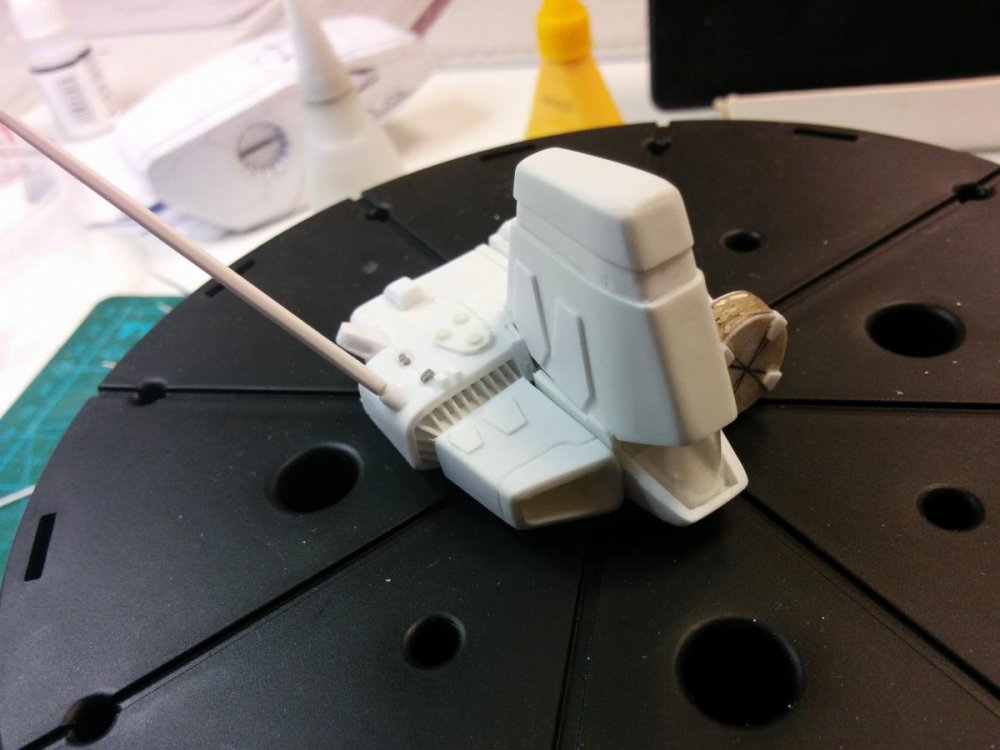

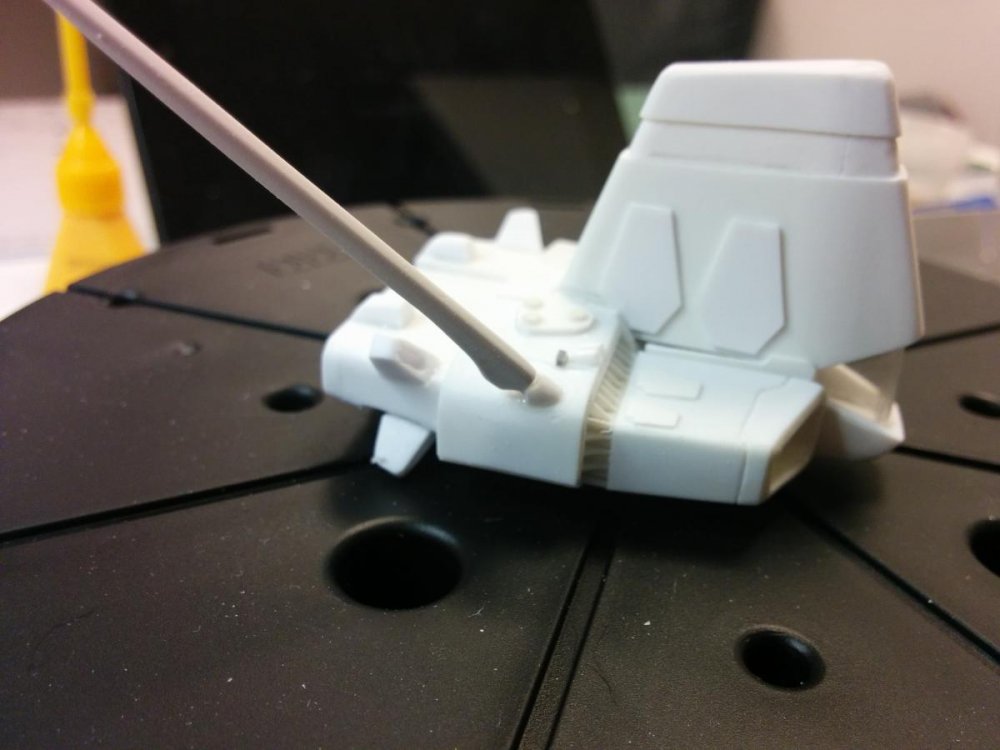

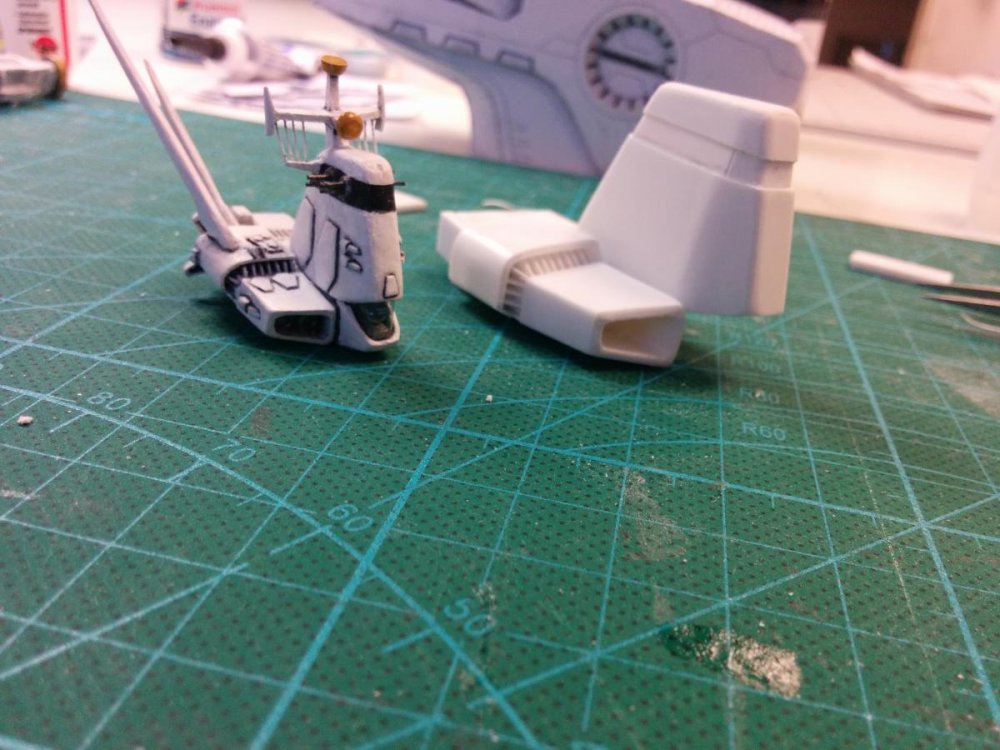

Evolution Toy - VF-2SS Valkyrie I 《MACROSS II ~LOVERS AGAIN~

in Toys

Posted

ordered mine from HLJ

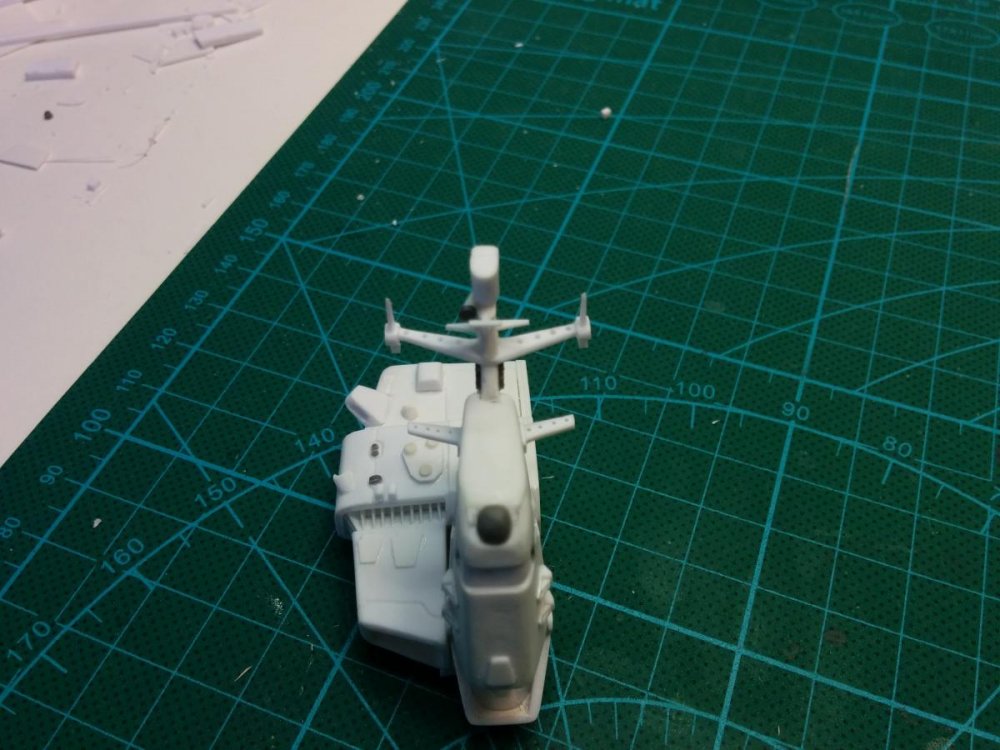

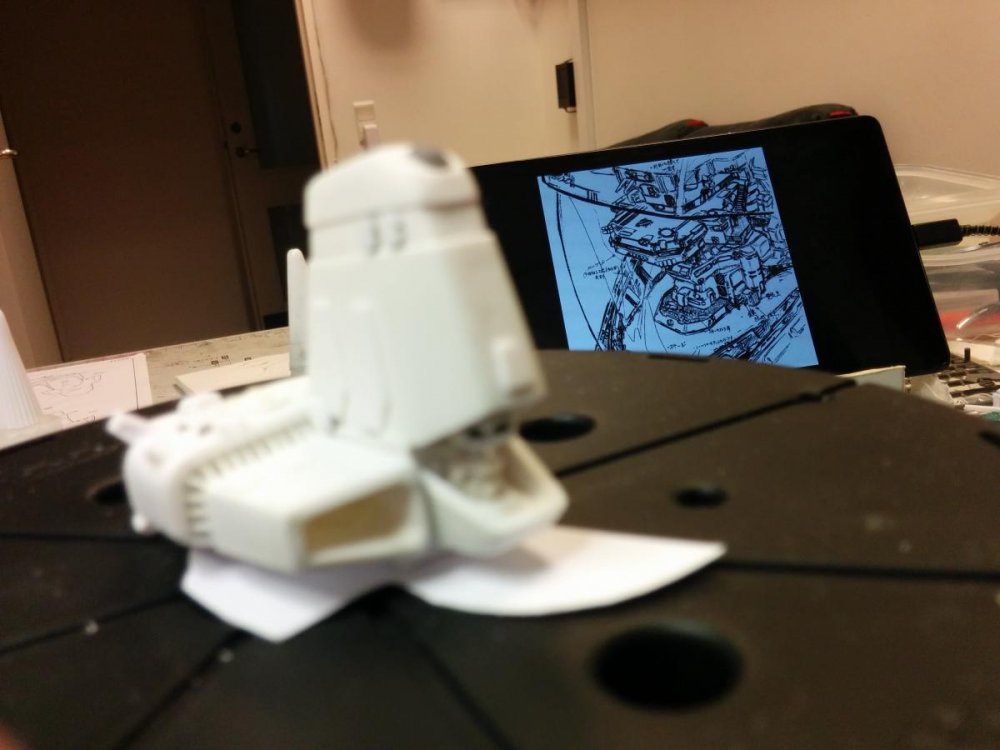

gonna redo some things on it though, and make a SAP for it!!!

also ill give it a proper paint job w/ weathering