-

Posts

267 -

Joined

-

Last visited

About Aztek

- Birthday 05/24/1976

Previous Fields

-

Old MW Name

aztek

Contact Methods

-

Website URL

http://

-

ICQ

0

Profile Information

-

Gender

Male

-

Location

Misawa, Japan

-

Interests

Macross!

Recent Profile Visitors

3434 profile views

Aztek's Achievements

Sharon Apple Concert Attendee (4/15)

16

Reputation

-

Hmm. I’ll check into that. Thanks!!

-

I have SLA for small and detail parts and FDM for the large structural parts. These joints look great. I just need ball joints/sockets that are 2.5mm diameter max to fit

-

Thanks! I’ll try those.

-

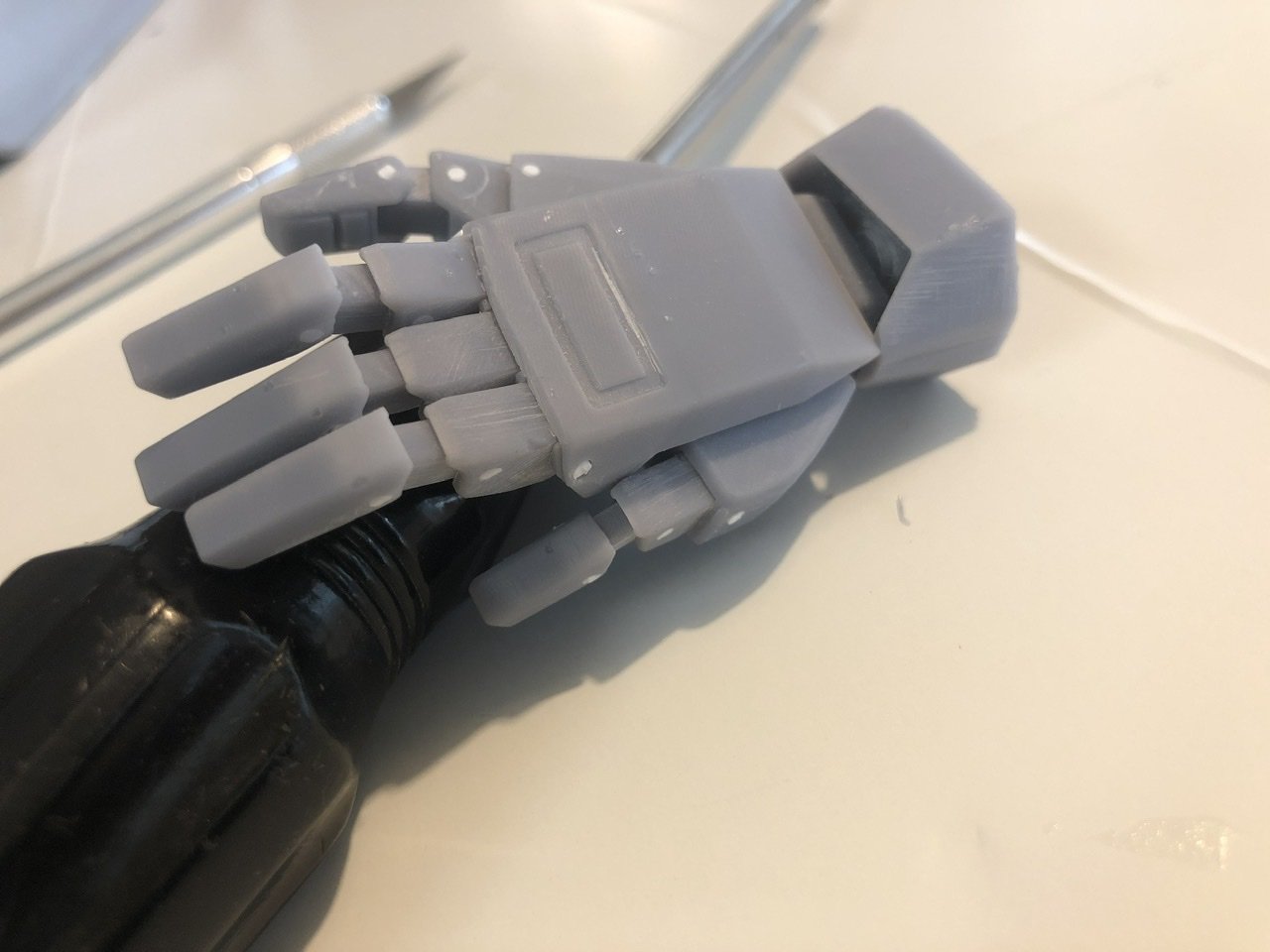

Minor update. Kinda Spent some time working on Hikaru to pilot this beast. I wanted a fully articulated action figure style pilot I could put in the cockpit or have standing outside. Trying to engineer the joints on such a small scale with a strong but brittle medium is a challenge. The stl is a static statue of Hikaru I got online but I split it and re worked the mesh at all the joints in an attempt for poseability. Hikaru stands at 8.9cm which is 1/20 of his canon 178cm hight. The hinge joints in the knees could work but be brittle. The elbow hinge joint is extremely small. Need to try a different approach. I have a small pin in the hand to attach to the forearm. It rotates ok. May upsize the hand a bit for strength. One of the photos has the pilot being held in my VF-1 hands. These are the old resin ones I did a while back. I’m still reworking the forearm mesh to account for the 8ish percent increase I scaled the hands based on the forum’s feedback. Do you guys have any ideas on the ball joint style that are in the shoulders, hip, neck and ankles?

-

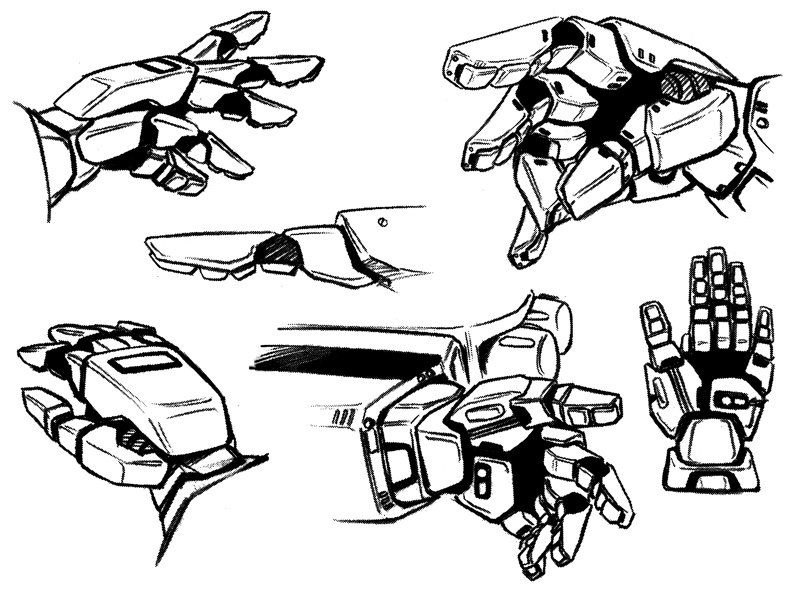

I’ve been struggling to make time with work/family/holidays lately but there may be some opportunity to work on some updates soon. I’d like to move past the hands/storage/size issue right now. Thx for the line art@nightmareB4macross but I’m torn with the way to go on this. Can definitely make the hands slide out vs. rotate, might even open some space for a larger hand. Just can’t get past there not being an environmental door or hatch that keeps the hands sealed inside. Does anyone have any screenshots or line art that shows forearms with hands stowed from the rear? I searched a few episodes from Macross and DYRL. Was hoping for a shot of the 3D valks in Delta but the angles were off. Thoughts? -Az

-

I did a quick adjustment with the mesh. Will also post a render tomorrow. One question, in the cutaway schematic, left arm, the backhand faces outward, which way is the thumb? Up or down?

-

Thanks for all the references and input. Need to go back and look at the joints and see if its possible. The thumb and pinky will be the challenge.

-

@nightmareB4macross do you have a link to the poster you are talking about?

-

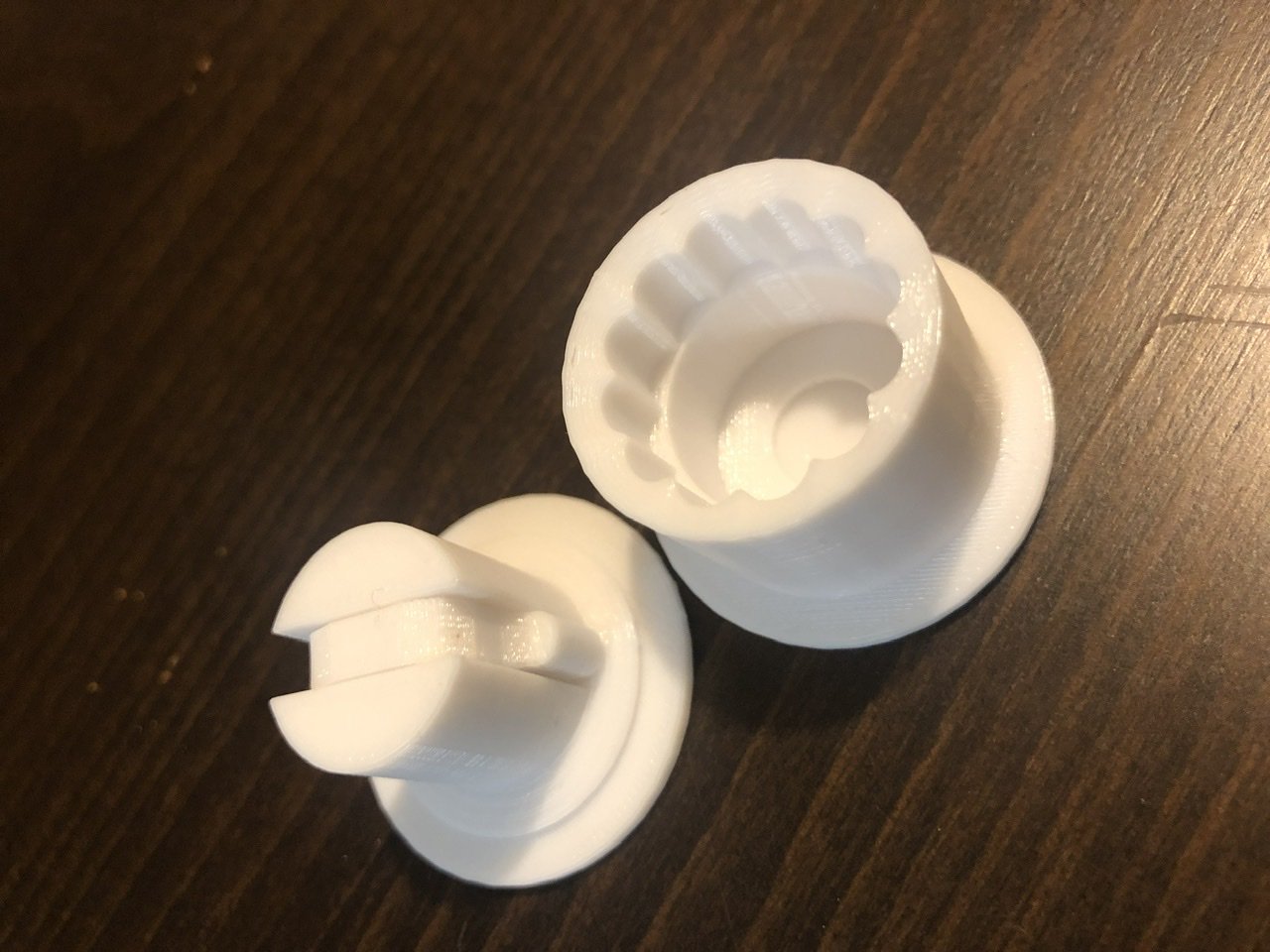

Man I’m trying really hard to see how that would work? I think I have an idea but think the washer contact area is too small for let’s say an elbow joint. It might need to be a rubber spacer 1cm wide or so.

-

@Sanity is Optional I’m not quite understanding that? Do you have a diagram or break down of one installed? I’ve taken apart a bunch of toys over the last several months and I’m not sure I’ve seen that yet.

-

Thanks all! The pins in the fingers are 1.6 mm and interference fit. Might not be able to get a nut/bolt in there. I'm thinking of draft printing the nose section next. So may be a short while before I get an update as there are multiple tweaks to the mesh I need to do for the pivoting radome, leg connections, canopy, etc.

-

-

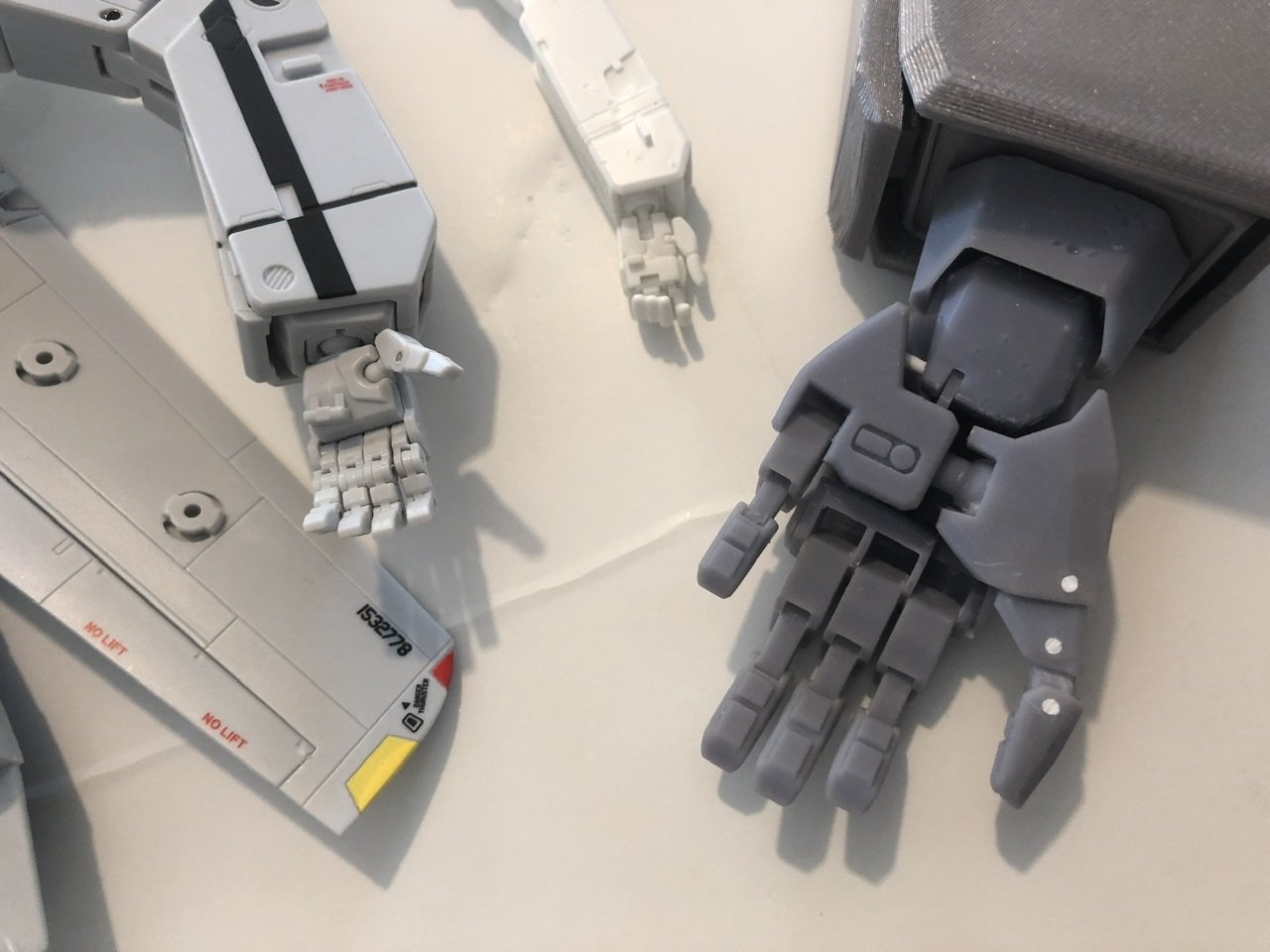

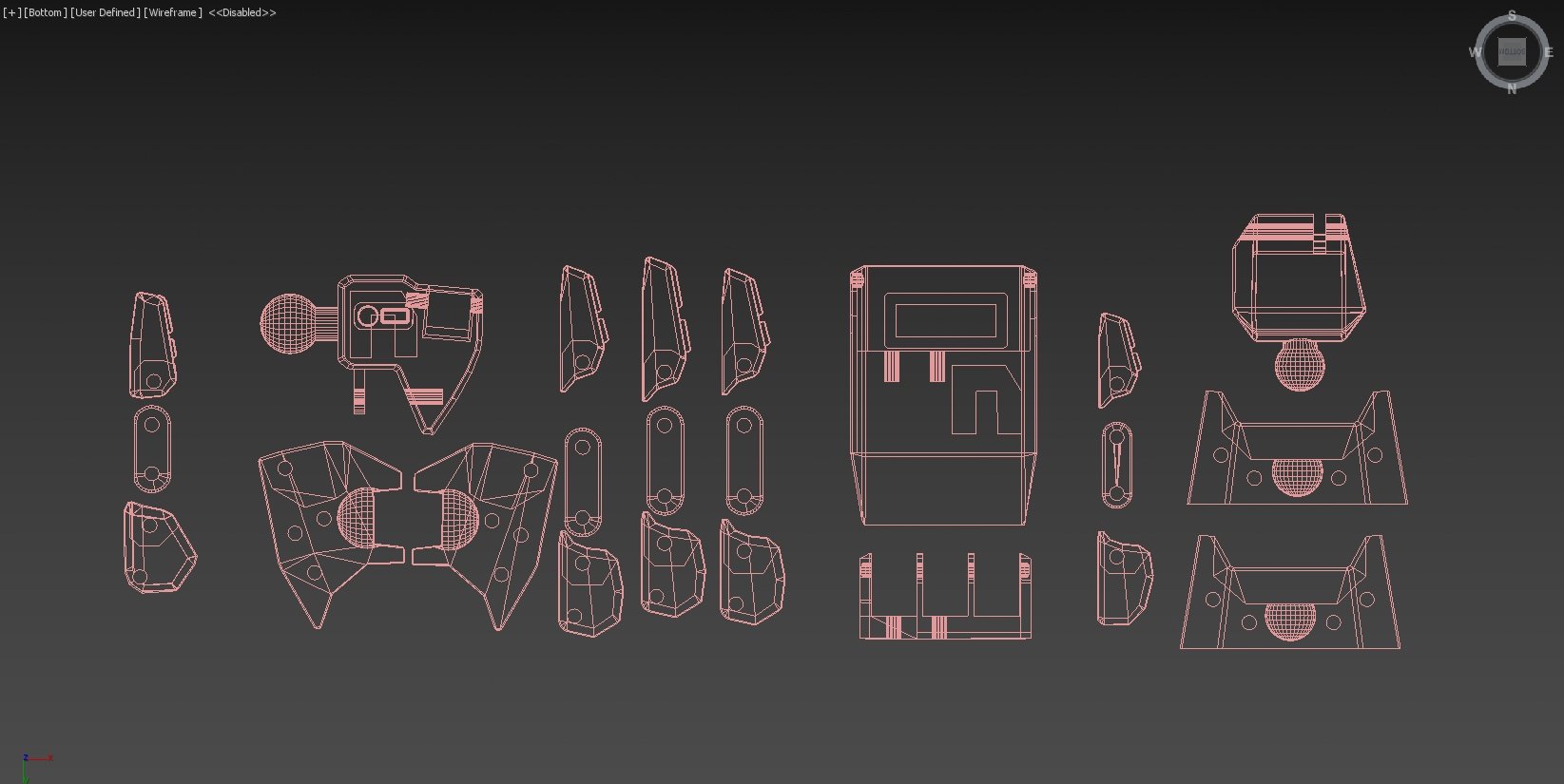

@MechTechnice! I'll post some prototyping below off I did off your original photos. I took a stab and instead of doing the flange pressing against the center housing I double flanged it. Printed in PETG, cycled a few hundred times bu hand. Great tension and no sign of serious wear! This joint will be perfect for the knee and may try to adapt for the shoulder joint. Your work is amazing. How strong is the styrene? The smoothness looks great in the photos. With FDM I'll spend a fair amount of time post processing. The SLA is awesome but not structurally consistent enough nor strong enough for the main structure. Today is a small but proud update. I got my SLA printer back up and wanted to do a detail test. I wasn't sure where to start. Since the hands are one of the more daunting things to get right (for me) I said screw it and jumped in to these over the 4-day weekend. The proud part is I used the attached line art to draw the original mesh back in '03 while deployed. The hands have hardly changed over the years and are one of my favorite creations. On the 1/20 scale I'm trying to get as close to DYRL canon as possible. Some things like the visible ball joints are required for function but the details like on the palm and back hand are critical. The mock up below has the 1/72 and 1/48 for comparison. The gray PLA arm assembly was the draft I first did so there are gaps and loose joints. The mesh is fixed but I don't want to print it again until I start panel lining, More photos following this post since I'm having a hard time not getting errors when uploading on my PC.

-

@MechTech would you mind taking a couple more pictures of that from an angle that can show me the way it’s built? I can almost make it out but would want to see the male and female pieces better.

-

@MechTech that joint looks awesome! I planned on nylon washers and metric screws with nylock nuts. How does it work for you? Strong enough? Does it break/chip? Is that SLA printed or FDM? I’ll look to reverse engineer. ☺️ I got my SLA back yesterday and have resin on its way. @Chronocidal I have an stl for a sliding/friction hinge and since the leg is so big I may go back and look at that as an option. Right now the model is easily over 500 objects. I’d like to optimize much lower and that just might help. Also I have the ratchet/nub inside the upper thigh portion to ‘notch” in the upper accordion grooves. Thanks!