-

Posts

509 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by THOR

-

-

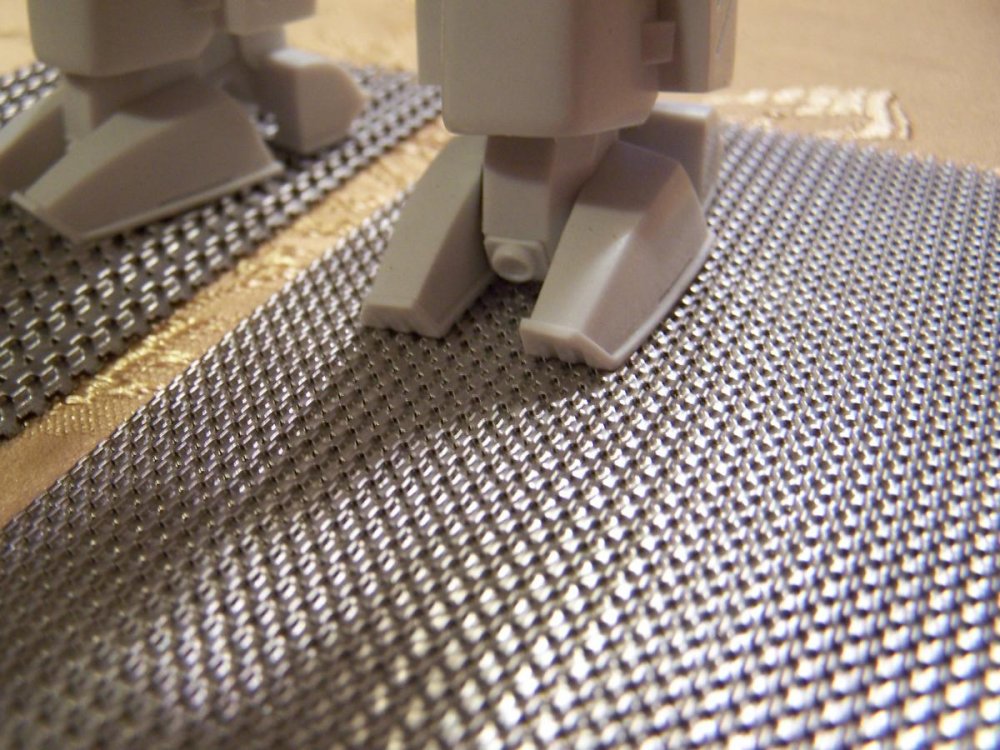

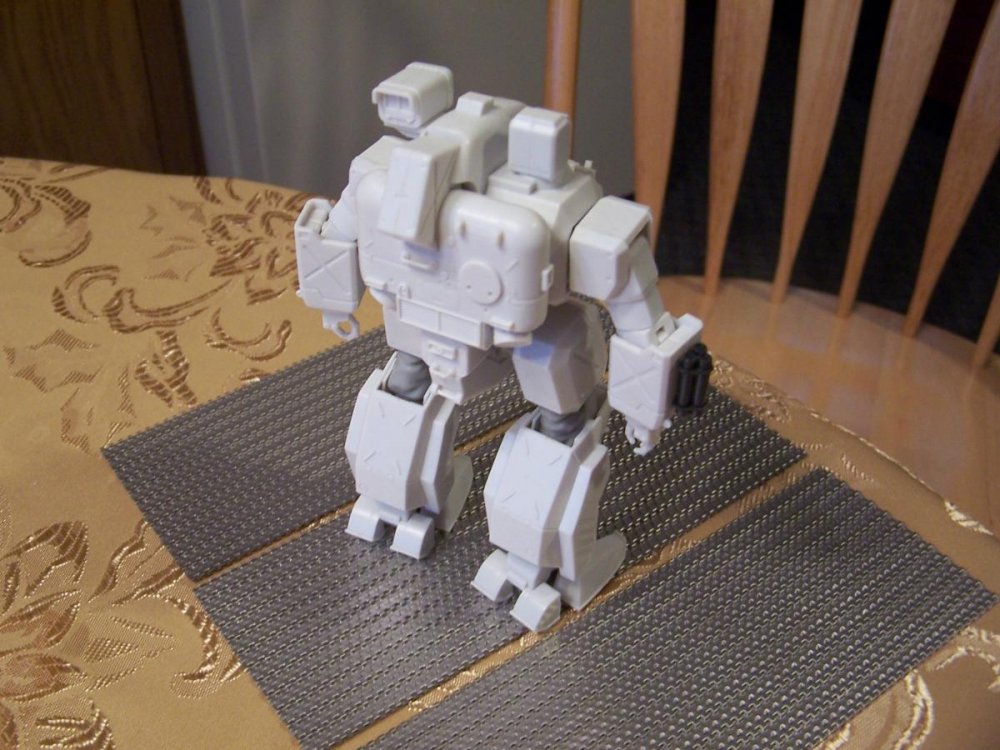

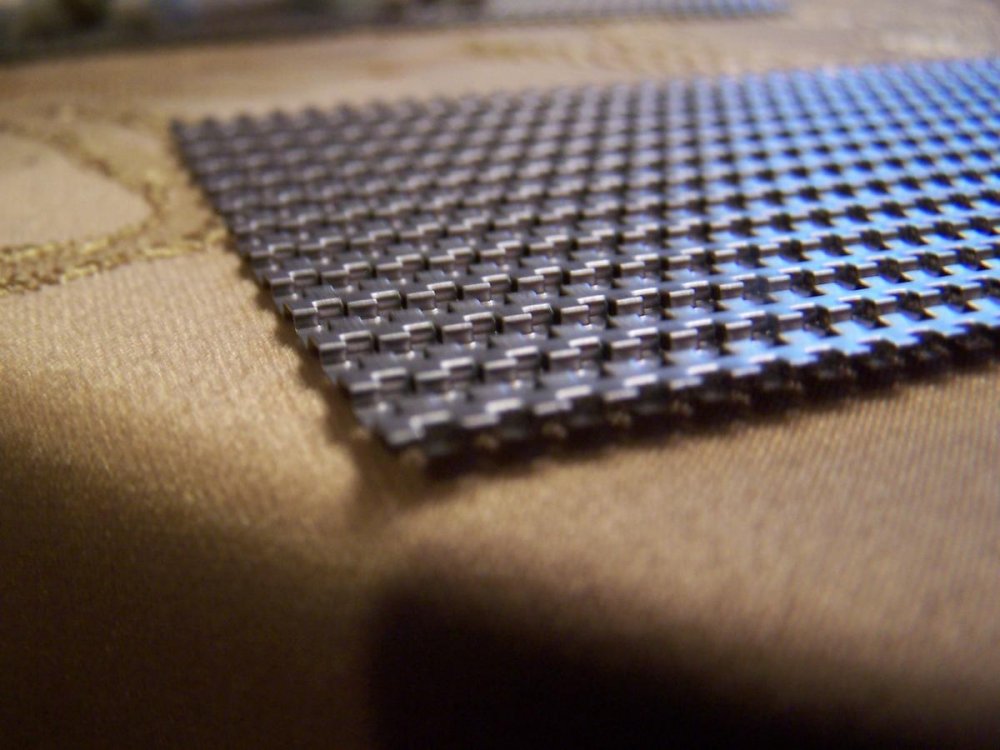

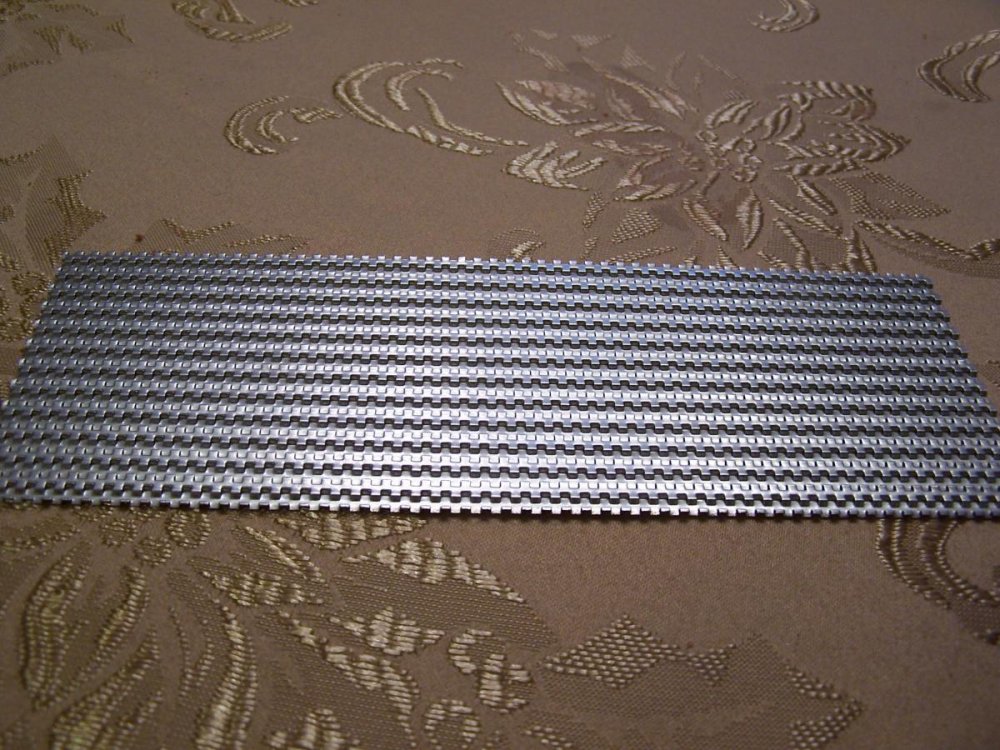

Got these stamped metal sheets that I thought you might be able to use for:

tread plate?

custom armor panels?

custom walls?

$1.50 per sheet paypal: (michaelwaynenellis@yahoo.com)

Free Shipping in the US! I can quote elsewhere. UK: 30-40 piece quantities will ship for free

7.0625" x 2.5625" x 0.047" (decimal)

or

179.387 mm x 65.087 mm x 1.2 mm (metric)

LET ME KNOW SMALL OR LARGE TREAD

-

the "sensor wing" was an epic fail. it basically was too thin and drooped within a few weeks. sending the file this week to our frend yeti to machine out of thick plastic or metal on his cnc router

-

please sign me up for a purple trooper!

-

i need purple accessories! and a v2!

-

I am finally back in business. I'll hope to cast up as much as I can over the holiday. Parts lost et. and re-made...

-

let me know if i can help, too. i just got back in the saddle with my computer and software so i'm back to doing 3d stuff again.

-

killer coolness!

-

For general knowledge...Yeti and I used the Badger sand blaster and an enclosed blasting cabinet. Sand (straigth from the beaches of Sarasota) seemed to leave pock-marks in our test piece. The aluminum oxide from badger is 220 grit and seems to work well with smoothing kits out. You can get the aluminum oxide in 220 grit much cheaper online than badger sells it.

-THOR

-

We bought a hobby media blaster....looks like an airbrush....gonna try and see if it takes down the roughness on that shapeways nylon...ill let you know if it works....will that fuselage fit in your tumbler? (i think you got a tumbler right?)

i'm gonna try fine glass beads, aluminum oxide, garnet sand, and baking soda...i'm guessing baking soda will be the mildest but that nylon is tough.

-

Nice work Yeti! Looks killer!

-

Gonna have to get this one to match my enemy pod!

-

what!? thats just crazy! what's next...a 1/24 MONSTER!

-

so fresh so clean

-

very nice...

-

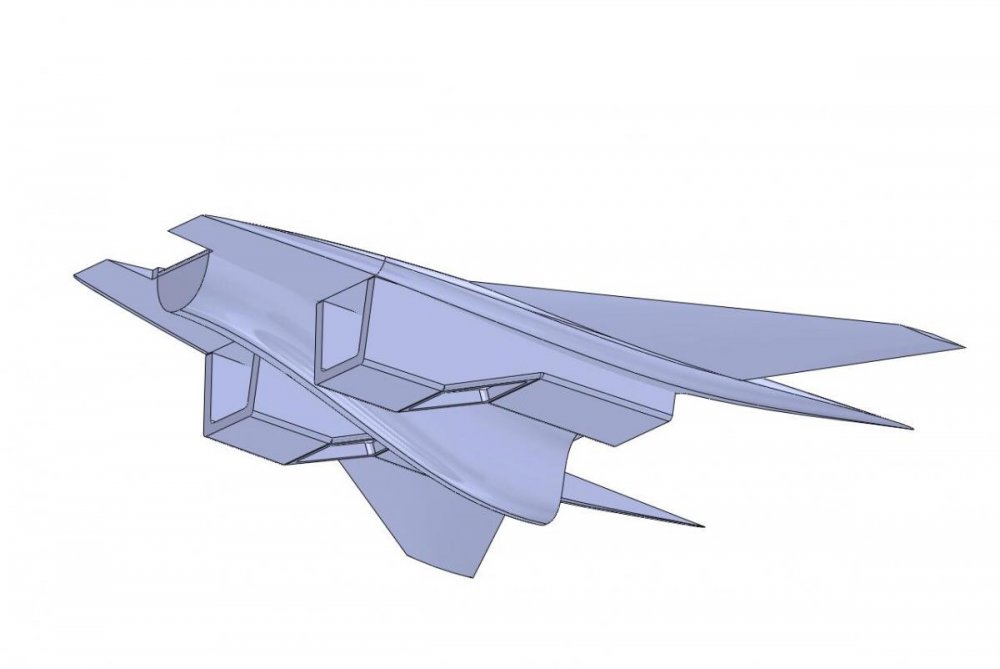

once in the computer i can scale the file to any size we want.

so yes...maybe a 1/48 scale dragon. let me cut my teeth on this lancer, first.

-

-

head looks great!

-

I've been working a lot over the weekends. I'm finally getting back in the saddle for this. Expect pics this weekend.

Hopefully you will like my landing gear and cockpit.

Reworked the vernier? thrusters to match the 1/48 Hase kit.

Had to thicken up the radar "wing" and will have to throw in a rod the keep it from drooping on you.

-

I know I'll probably do the blue/white version with mine but I wonder if anyone is planning to do the red or green or something else?

Gloss red would really pop on the table.

-

yes, make a monster for me!

-

awesome!

-

shweet!

-

all heck...add me to the buyers list!

-

That's a tough piece to fix because there is little bonding area between the two broken pieces and the whole unit is subject to multiple forces of tension and bending stresses. I would superglue or epoxy the two pieces together and then i would back up the whole side with a new sheet of plastic to stiffen that whole side. (if it didn't affect the function/design)

Cool Chem makes some great stuff...basically a hybrid super glue and epoxy.

Tech Bond is similar.

I could print out a whole new piece for you. Send exact dimensions and we can make it out of nylon or even metal.

-THOR

Custom Stamped Metal Sheets for your Diorama

in For Sale & Trade

Posted

Free in the US. Sorry.

I can get you a quote outside the US.

The USPS has a flate rate box the size of an old vhs tape. I quoted someone in the UK 30 pcs for free. Less than that, I lose.