-

Posts

509 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by THOR

-

-

Hello,

This project is sooo cool. Can't wait to get my copy.

I have a question for John.

How did you create those curves?

I can cut out the blocky parts easy. It's the compound curves that give me fits and make me throw up my hands to solid modeling and cnc stuff. I'm going to run into this problem on the "calves" of the Tomahawk I'm going to start once I wrap up my Spartan.

Any tips?

Thanks for doing this wonderful kit, btw.

-Thor

-

Sweet!

Keep it up! It looks great!!!

-Thor

-

Hello Everyone!

I'm in the middle of moving into a new house. I'll be back to work on the Spartan in the middle of July once all of my stuff is settled down into my new home.

The arms, knee/hip joints, missile bays, weapons, and cockpit are what's left for me to do.

-Thor

-

Sweet-1

Yes, this could be done but I believe there are VF-11 kits and toys already out there in 1/72.

-

MAN OH MAN!!! You had me at hello!!! A 1/32 Cats Eye!?!? Sign me up.... (and I know a doner...named...me ...how about we start with the Fan racer though...mmm..1/48 Fan Racer...must make everything 1/48!!! )

Hey Jesse,

I love this stuff and doing the Fan Racer would be an excellent choice. We should definately work out the details and a schedule once I buy a CMM arm or convince another friend of mine to loan me his. Then we can make any scale we want of anything we want once I generate a solid model.

Holy crap, you're living my dream!How much does a machine like that cost?

Damn, if only my school is rich enough to be able to afford one of those for its students. I could spend my life in there and not get bored.

Stamen,

The sky is the limit on the price for these things. I'd say $2K-$30K depending on options. The coolest option is a laser scanner attachment.

-

Hello,

Wow! Please don't forget me when these kits become available... Thanks for all of this hard work!!!!

-

Wow,

I made the list!!!!

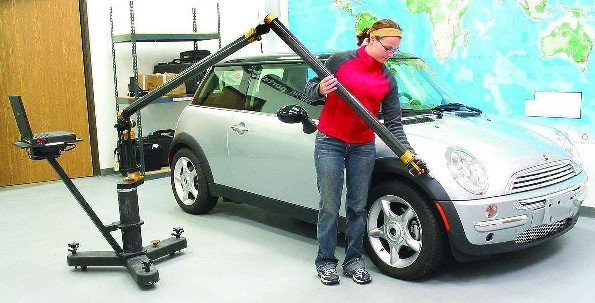

The Spartan is in a shoebox until I get moved into my new house/job in Sarasota. I'll hit it full force in July. BTW I'll be looking for a small CMM (coordinate measuring machine) arm this year like this photo to reverse engineer some of the rarer kits.

Basically I could trace the arm over say a Cat's Eye model or peices and build a 3D model in the computer to later cut out on the CNC in ANY scale!!! My dream is for a 1/32nd, but 1/48th would probably be wildly popular. I'd just need a donor Tanmen kit.

-

sweet!

-

Looks like I'll have to do the YF-23 next along with the A-12A Avenger II and Monogram's F-19 Stealth Plane from the 90's.

-

I bought my blower from a Industrial Supply company in Fort Myers, FL. I think it cost me ~$65 brand new. Look for at least 250 CFM (cubic feet per minute), 110/115V and you can put it on a dimmer switch to slow down the air. Also remeber to find a blower with the motor outside the exhaust stream.

Brand New from www.grainger.com:

http://www.grainger.com/Grainger/searchresults.jsp

You might be able to find something similar on Ebay:

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewI...3818888721&rd=1

As far as the plans, I'd have to dig up that old Model Railroader magazine and scan the pages. I'll see if i can do that because the article had great information about the electrical hookup, etc.

Hope this helps...

-

I don't think there is an "official" designation yet.

http://www.globalsecurity.org/military/sys...rcraft/x-44.htm

http://www.lowobservable.com/usprotos.htm

http://www.globalsecurity.org/military/sys...craft/fb-22.htm

http://www.popsci.com/popsci/aviation/arti...,262063,00.html

-

Nied,

You read my mind...

-

-

-

-

-

-

-

-

-

The Tomahawk is definately next since it is the bad@ss of the group. The Defender and Phalanx are natural follow ups since they share almost identical legs with the Tomahawk. If I did my math right, a 1/35th Monster body would stand ~25" tall, ~13" wide, and ~22" long. The barrels would be 1.8" in diameter and ~28" long! Muuuaaahhhaaaahahhaaaaaa! Sorry, a maniacal laugh can be heard from my house every so often as I work on these Mecha.

Those pieces would definately weigh a ton. To reduce weight by making hollow pieces, somone would have to look into rotational molding to cast pieces of that size.

I think that Cheyenne from Macross Zero would be cool. I love the destroids in Macross II as well. The VF-2SS SAP, armored VF-O, VF-1, and VF-11 kick major booty as well.

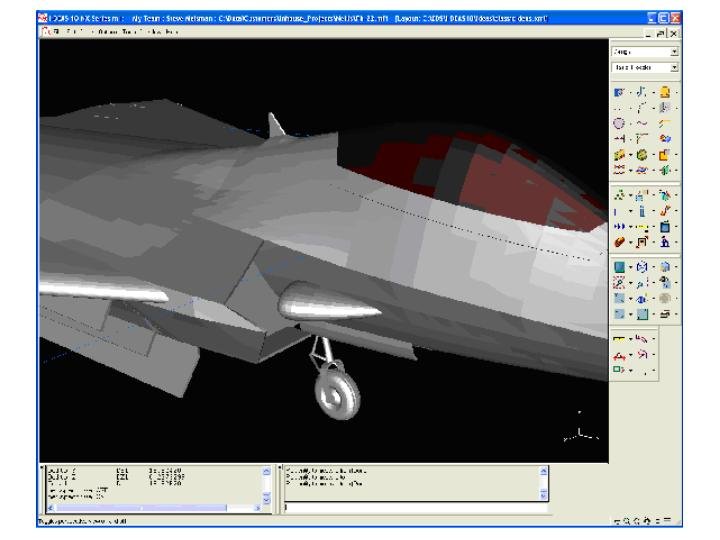

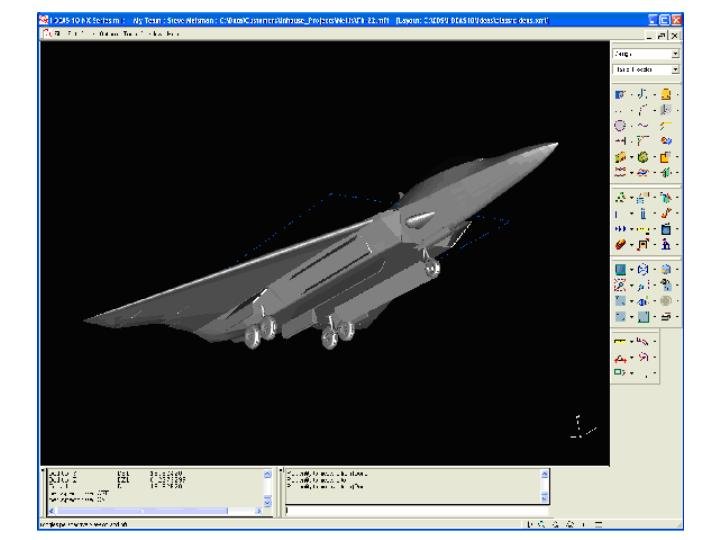

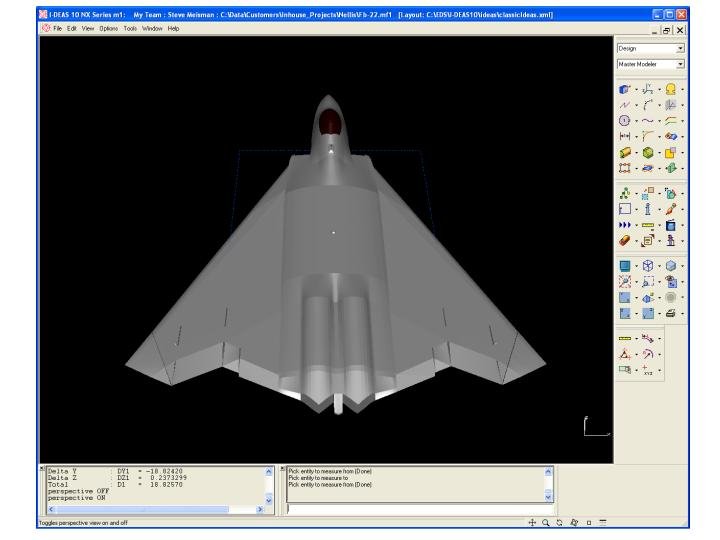

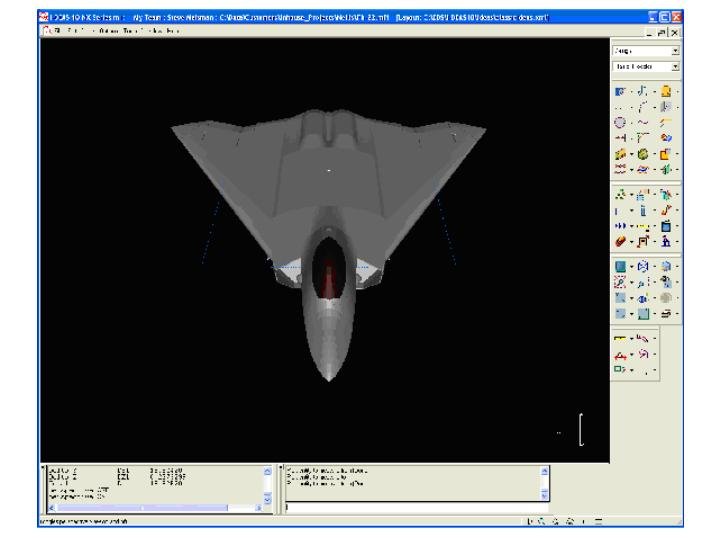

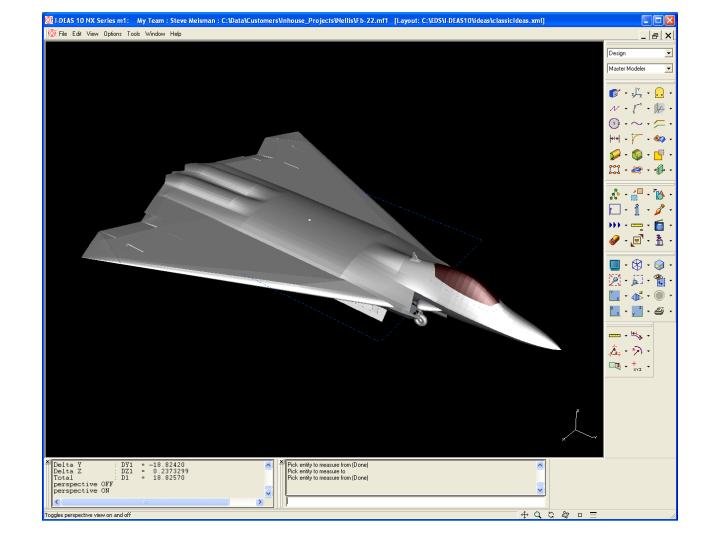

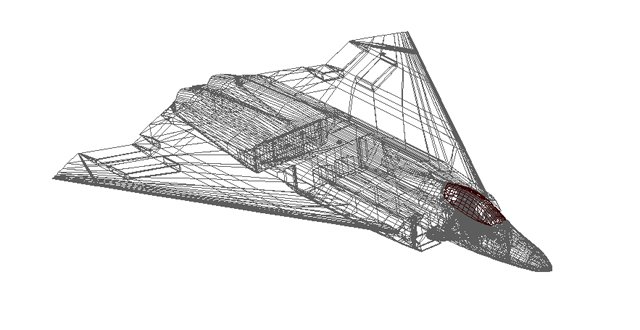

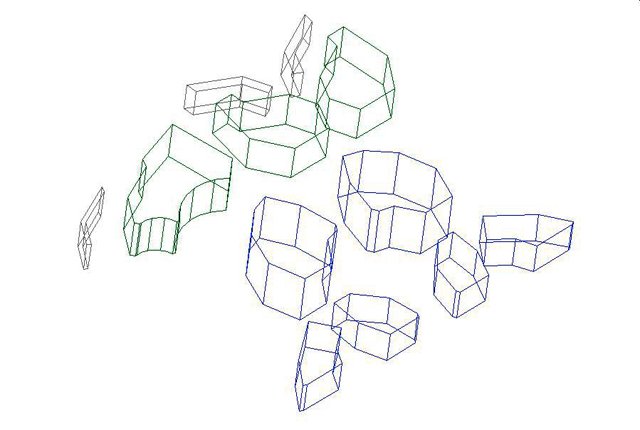

Check out my 1/32 FB-22 Manta (B is for bomber) I'm doing for a DoD friend:

-

mbs357,

The CNC router is actually a close friend's machine. I do consulting work with/for him when I'm not at my regular engineering job. I help him with various technical and business problems and he helps me with various projects I do.

The bridgeport was actually mine until a few days ago. I bought it 3 years ago for a great price and set it up at my employer's shop with the deal that my company could use it and I'd have a place to store it/use it. My garage is just too small and not hooked up for 220V 3 phase power... Since I'm currently changing jobs my old boss asked if they could buy my bridgeport and keep it since they've become dependant on it. I'll just buy another bridgeport or just use my smaller bench top unit when I get into my new job/house. My plan is to do most of the larger pieces with my buddy's CNC and do detail machining on my bench top unit.

I'm eager to get my Spartan done in a few months and start working on the other destroids. After that, who knows. There's a ton of other sweet Macross mecha to do and other projects I have in mind. I just wish this was my full-time job. Oh well, I'll just have to start playing the lottery.

-

-

Can somebody ID this mecha from 'Perfect Memory'?

in Model kits

Posted

Please ad me to the list if there's a recast. Please!

everyone keep their fingers crossed that hurricane Charley misses my new home in Sarasota.