-

Posts

570 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by tundrayeti

-

-

My wife said that's her job!

My wife said that's her job!

Just don't use automotive polishing compounds. They can be petroleum based, can melt or crack the plastic, and may have wax in them making painting impossible.

I'm gonna try my wife's shirt with her in it next... - MT

be careful. That can lead to other things.

-

crocus cloth works well too! There are also tons of plastic polishes out there depending on what it is. Be cautious, the wrong polish can end....badly.

-

Wow that came out AWESOME!!! Always knew there was a reason all the bridge crew were female...Global was such a letcherous old man.

-

Got it from a recycling place. Got a good deal on it. Needed it for the 1:1 gallant parts.

-

Nah, spellcheck on the ipad is weird sometimes.

-

Lol ive actually hired 2 workers. I will have everything including my new kids ready to go by mid may. Bought a huge new pressure pot and im casting like mad to get all the new parts for kit done. Ill keep everyone informed. Im also working on the instructions.

-

Blender will import max files

-

Interesting. I may be willing to part with a modified version of some of my 3d models. I set them up for 3d printing, but i can convert them to 3d studio max or whatever.

-

Well the pistol kit will go for $125 and the rifle stock and barrel extensions ( shoulder strap included ) will be $200. Painting will be extra so please send me a PM

-

I will have one painted up for display at Wonderfest.

-

I always wanted one too!

as for the why 1/350th? Ill let Neptune answer that one, but i know 1/350 is pretty popular. And the main body is over 10 inches at 1/350th. So 1/72 would be the size of a minivan.

as for the why 1/350th? Ill let Neptune answer that one, but i know 1/350 is pretty popular. And the main body is over 10 inches at 1/350th. So 1/72 would be the size of a minivan. -

Oh yeah! already been getting inquiries. I'm getting ready for Wonderfest. I have been working with Neptune Survey on a few things and some other goodies as well. So I wont start until after mid May. There

was mention of an ARMD launch bay hanger type ot diorama.....

-

This will be avaliable for sale. I'll have them at Wonderfest and you too can have one of your very own. The gallant too.

-

-

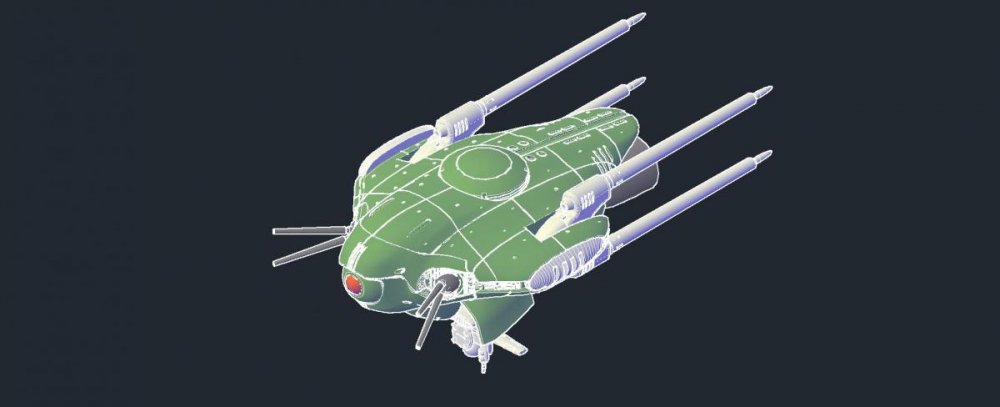

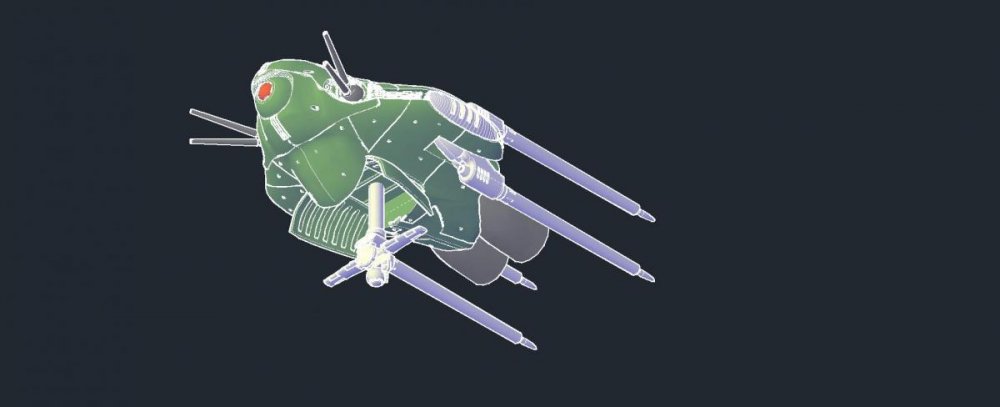

Wow very cool. This might be appropriate then. Neptune Survey has commissioned me to do a Bug Eye scout in 1/350. here is the 3d model. I'll post pics of the master when it is finished in a few weeks. Also another upcoming goody for Wonderfest. A 1:1 gallant H-90 sidearm. Almost done. This will be casted soon. pics were taken with my iphone so be gentle lol.

Enjoy!

-

Still getting everything boxed up for shipping. I want a few of these for Wonderfest as well.

-

-

Well Its about 6 weeks till Wonderfest in Louisville kentucky. I know there will be several macross World members in attendance and a few of us will have some new Macros and other various new items.

I figured we could maybe schedule a get together, and let some folks see some of what's coming.

I'll have some items of interest her to show soon as well as finishing my backlog of projects.

See some of you there

-

Nice Alaska base 1A! - hopefully Tundra Yeti will do the Kitchen Sink in 1/60 to go along with it...

Eventually. Sometime this year. 1/100 scale is up next but not until I get the 1/72 finished. Wonderfest is in 6 weeks and Got some really great goodies coming for that too. I'll be posting in another thread.

-

I have looked into getting my own 3d printer for a long time now. With the costs involved and the maintainence, it is much more cost effective for small guys like us to get the prints done. The build materials are expensive and larger companies can buy in bulk and get discounts. etc etc. I still hope to get one someday, but i have found some really excellent 3d printers that do high quality work with no steps. They may be more expensive than shapeways, but the time I save with finishing makes it worth the extra cost. All I have to do is throw them in rubber and start casting!

-

TER-OR, one of the best things about this site is that folks do understand that life happens. Thanks for making this kit so much better.

-

Kurisama, have you considered just 3d printing your models as masters and casting them? Trust me i use this process and it's much more cost effective and easier to keep track of your sales. Dont get me wrong, i used to love shapeways, but their quality and pricing has undergone tqoo many radical changes over the last few years for my taste. There are far better 3d printing companies out there, that make a part that needs no cleanup. All you have to do is throw it in some silicon rubber and make your resin copies. This allows you to use 3d printing to make high quality prototypes and then copy them using resins that are much stronger. Just my 2 cents but its working well for me. If you dont have the skills or knowledge, hit up some of the members on this forum, usually everyone is eager to help.

-

Final price will still be $115 plus shipping. Let me get out the prepaid guys first and then I'll stgart taking money again. If anyone will be at Wonderfest in Louisville, I'll have them there too. I'll also have some other goodies as well

-

Love those vehicles! Nice to see they found a new home.

1/350 scale Zentran Bug Eye Scout model kit

in The Workshop!

Posted · Edited by tundrayeti

Hey everyone. I have been Collaborating with NeptuneSurvey on a 1/350 Bug Eye theater scout. Well i am now in the casting process, and will have this avaliable at Wonderfest this year. Anyone interested in getting one please PM either Neptune or Myself. Below are some of the cad pics and the Master before finishing work has been done. I will post some updated pics this weekend.

Prices for this will be posted once Neptune and I get everything sorted out.

Enjoy!