-

Posts

863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Rodavan

-

-

-

-

-

I use Rhino3D , and I model in NURBS , old school . Try Blender it is free, a very good polygon modeler.Lots of help videos and lots users .

I come from an engineering back ground , so I like CAD tools . I use Cinema4D to render .

I also do a lot 3D printing , more engineering stuff .

-

-

On 7/11/2017 at 6:34 PM, peter said:

That's a shame to hear. Would have been nice to see this thing through.

Holy crap, 7 years ago though.

Wow time flies

-

Cool Lego's

Cool Lego's

-

Wow big print , I like ABS much smaller prints that you "glue " together .

-

Great work

- I would suggest work a parametric model program to make changes a bit easier . I have done some stuff on FreeCAD not too bad for a free parametric model software , once you get the hang off it quite easy to model and edit .

- I would suggest work a parametric model program to make changes a bit easier . I have done some stuff on FreeCAD not too bad for a free parametric model software , once you get the hang off it quite easy to model and edit .

-

Nicely done

-

Very cool models

Just remember to make plan for sanding as the end product is a bit rough and will need to be sanded down .Is the models thin walled or solid ? What scale do you intend to use for print ?

-

Send me your mail address and what format you want it in - currently in Rhino 3D

-

Cool design

-

Maybe you can print a version of arm - I still have CAD version of that arm some where ...

-

-

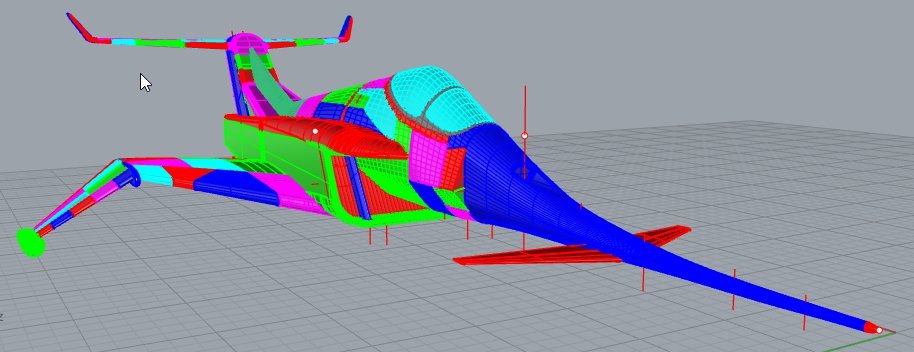

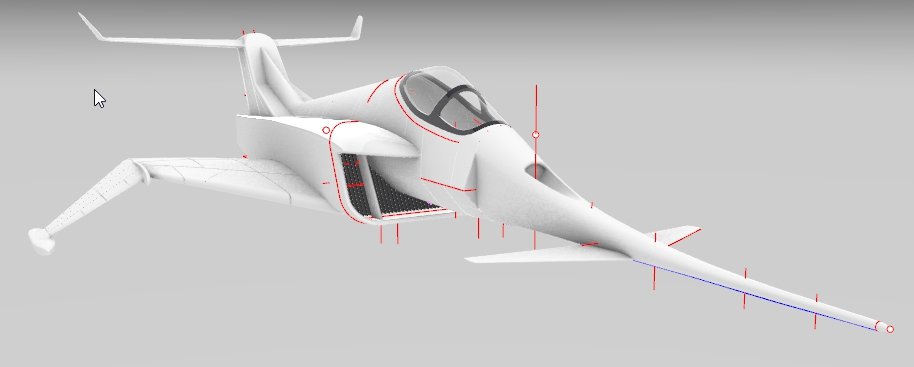

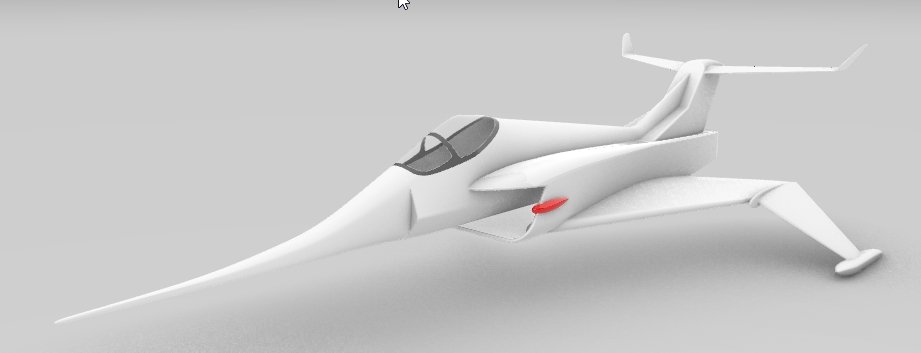

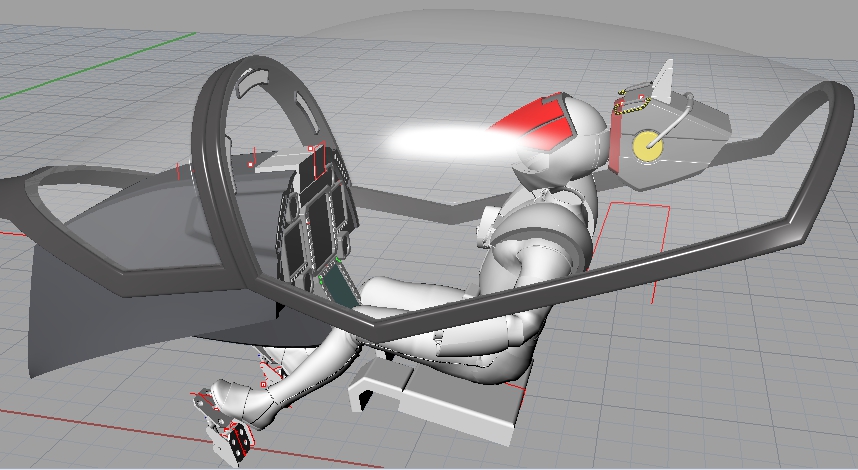

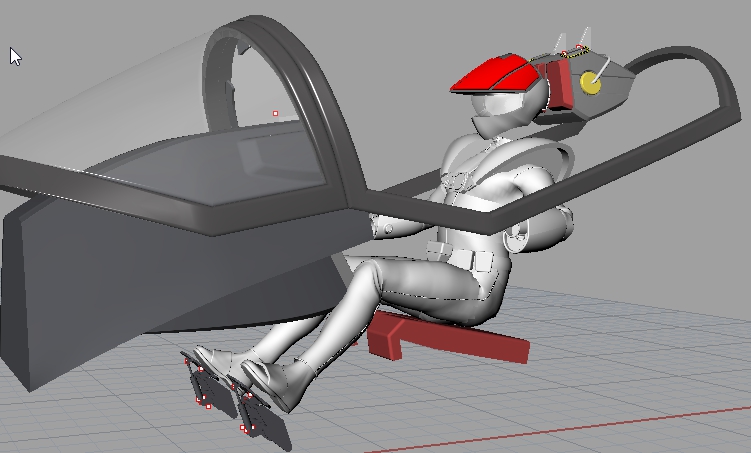

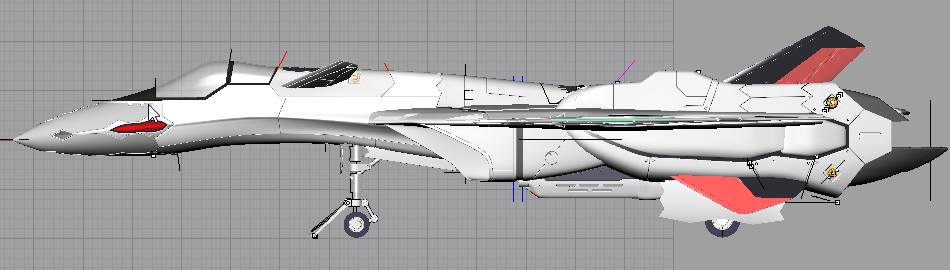

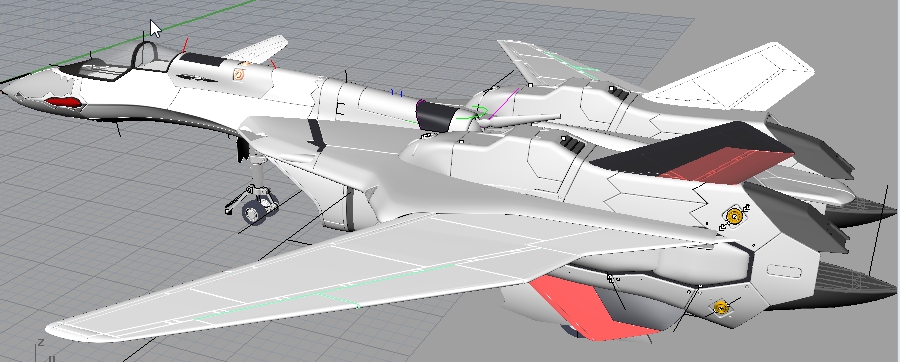

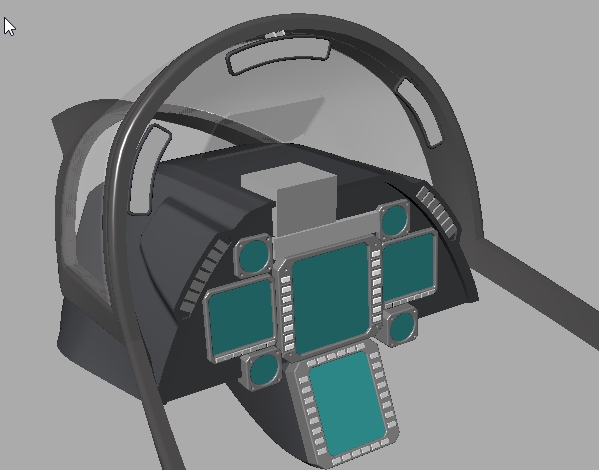

Hi 3D- Brainx

Nothing that fancy , they are CAD points , like lines and surfaces , they are place holders ( ref points ) I reuse while working or measure from .These are pics from Rhino3D , everything except for pilot is surface model ( CAD), not polygons.

Once I have modeled it all , I will convert to polygons then export to Cinema4D or Blender.

-

-

The whole process is based around the mold - how good it is and the process around it .

Maybe slightly off center to this topic - Arcadia and Other companies uses old established methods of production that has not changed in many years same process , same waste and same issues . We , us the customers pay for all the processes used even hidden ones - R&D , mold design and even the guy that removes the waste is factored in by a "bean" counter ( financial ). They would not start a project if there was any indication of marginal profit , we still pay for injection molding machine , even if it is paid for because it then becomes cheap profit .

What would be interesting would be to look at the old versus something like 3Dprint , manufacturing on demand ... That is future where small companies will manufacture on demand. Any just my thought.

-

Will think about it - I have a old Rapman 3.2 3D printer , but real world pressure has been bad last year so only did a tests . Maybe after Sep 2017 when most my real world projects finish . What printer do you use and what scale are you thinking off . I will need to tinker with this model of course

-

-

-

-

Great then modeling is all sorted

-

Doing the 3D model is easy , getting the sizes correct is the issue . If somebody can do a small sketch with some sizes or supply some reference material that will help .

Not Macross - Holiday modeling

in Fan Works

Posted